Checkline ETW User Manual

Page 4

Electromatic Equipment Co., Inc.

-4-

2.0

PCFE DESCRIPTION

Select port:

select communication port you wish to use to communicate

with the wrench

Change password:

Type current password. Type new password. Confirm new

password

Current mode :

Select mode you wish wrench to operate in. Selection will

take effect after data is stored using ‘store to wrench

button’

Current units:

Select the units you wish wrench to operate in. Selection

will take effect after data is stored using ‘store to wrench

button’

Current language:

Select the language you wish wrench to operate in.

Selection will take effect after data is stored using ‘store to

wrench button’

Wrench span:

The span of measurement of the wrench for example Span

100Nm would have a range of 2-100Nm.

Period of calibration: Set number of days to next calibration or it can be set by

number of measurements.

Calibrated on:

Date of last calibration.

Activate calibration:

Acti vates the calibration option in the wrench menu. You

must begin calibration before the wrench powers down.

Default calibration:

Allows wrench reset. All data/settings stored in the wrench

will be cleared and default calibration values for the

wrench’s specific calibration span will be programmed.

Power off wrench:

Allows soft power down of the wrench.

Store to wrench:

Store all current pc front settings to wrench. Wrench will

automatically power down after store.

Load from file:

Loads a previously created file containing preset data, into

the PCFE front preset window (top left).

Save to file:

Saves PCFE displayed preset data to file.

Clear all presets:

Clears presets from the PCFE presets window.

Set a preset:

Click on any preset location number in the PCFE presets

window. Set the required nominal, min, max Tolerance and

units. Store settings to the wrench.

Continuous upload:

Allows real time communication of measurements to the

PCFE. Wrench must be connected to the PC.

Electromatic Equipment Co., Inc.

-17-

5.3

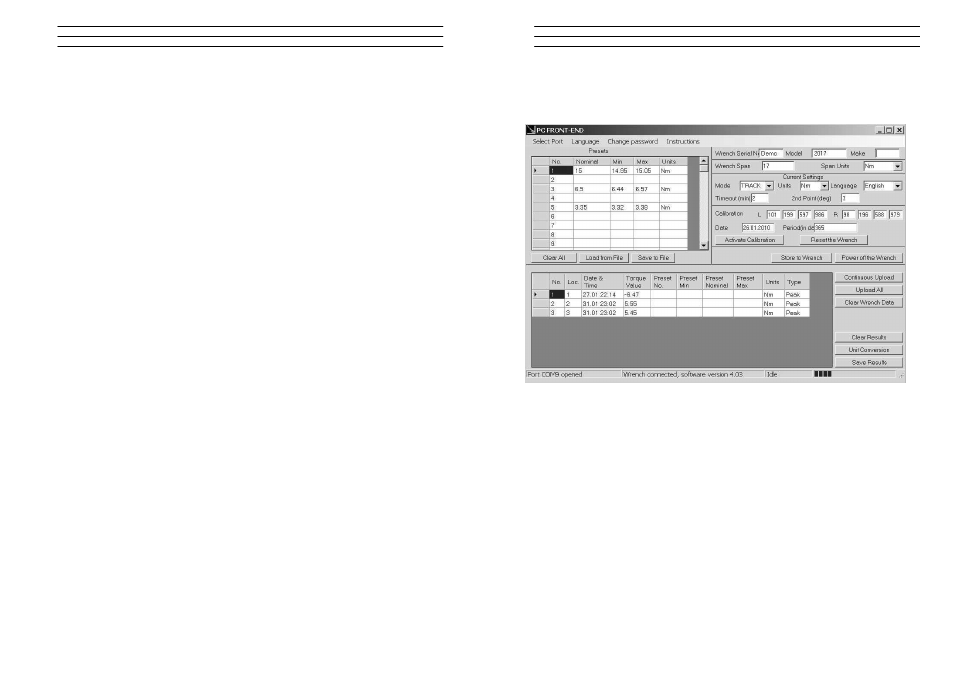

PCFE Window

The Top half of the PCFE displays Wrench Configuration data, the Bottom section

allows the user to manage the stored wrench data.

The right upper half of the PCFE windows, displays data such as Wrench serial

Number, Make, Model, Wrench Span and Units of measurement. The date of

calibration and the period of calibration are also shown in this section.

The left upper section displays the Presets stored in the wrench - the user can

choose to use the PCFE to set the preset's or it can be done manually on the

wrench.

The bottom half of the PCFE window displays any stored measurements on the

wrench It displays wrench location number, date and time of reading, Torque

readings, Preset data, units of measurement and the mode that was used to take

the torque measurement.