8 .2 pulsation of a pump module – BUCHI Pump Module C-605 User Manual

Page 42

8 Troubleshooting

42

Pump Combinations Operation Manual, Version E

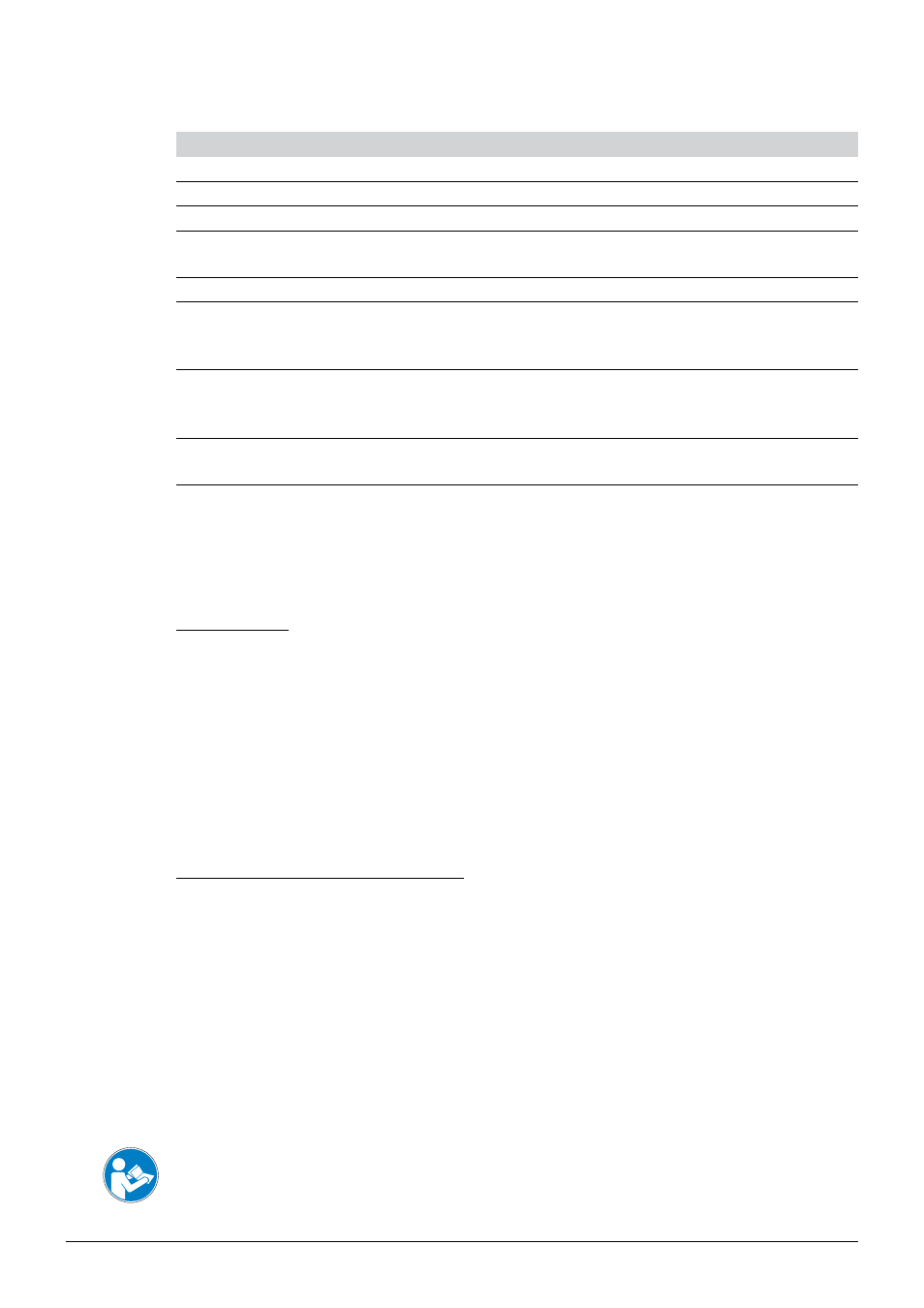

Table 8-2: Error messages of the Pump Manager C-615 (cont.)

Error number

Possible cause

Remedy

22

Cooling fan in pump B not working.

Contact Customer Service.

23, 24

EEPROM C-615.

Contact Customer Service.

26

Pressure higher than max. pressure settings.

Lower the flowrate, if possible, increase the max.

pressure

27

Unexpected restart.

Restart.

28

Check solvent level A.

Refill solvent bottle A.

Check level sensor position.

Check level sensor adjustment.

29

Check solvent level B.

Refill solvent bottle B.

Check level sensor position.

Check level sensor adjustment.

30

No pressure sensor connected.

Check connection; otherwise, contact the BUCHI

customer service

8 .2

Pulsation of a pump module

A repeated strong pulsation of the pumps suggests that the opening or closing times of the inlet or

outlet valves are not correct.

Possible causes:

Improper use:

• The solvent filter is not used. When the filter is not used, particles, dust and fibers can enter the

valves and affect their functionality.

• The sample mixture is introduced to the separating column with the pumps. The pumps are exclu-

sively designed to pump solvents.

Using technical solvents:

Technical solvents are normally not free of polar residues. Especially during extended standstill periods

these residues can adhere to the polar surface of the sapphire valve seat or the ruby valve ball and

influence the closing speed. In the worst case the valve can jam.

Possible sealing abrasion in the outlet valve

Each sealing is subject to a permanent abrasion during its service life. This abrasion is especially high

at the beginning during the so-called running in phase of the sealing. For small flow rates the flow

speed within the valve might be too low for a self-purification of the valves. For continuous flow rates

of under 10 ml/min we recommend to rinse the pumps at least once a week according to the proce-

dure described below.

Solving the problem:

• Rinsing the pump module:

– Disconnect the pressure tubing between the pressure sensor and the injection system, so that

the rinsing solution does not contaminate the separating column.

– Rinse the pump module with a high flow rate with ethanol or chloroform ( >150 ml /min for two

minutes).

ATTENTION

Do not pump the solvent round in circles. The solvent may only be reused after distillation.