BUCHI Pump Module C-605 User Manual

Page 23

5 Putting into operation

23

Pump Combinations Operation Manual, Version E

Pressure tubing 1/8” x 1/16”:

1

2

Cut the pressure tubing to the desired length. Attach

the fitting and the ferrules to one end of the tubing

as described.

Screw the fitting into the upper output of the

separator head a. Make sure that all fittings are

hand-tight.

Inlet b is only needed if two pump modules are

used. If only one pump module is used it has to be

shut with a blind plug.

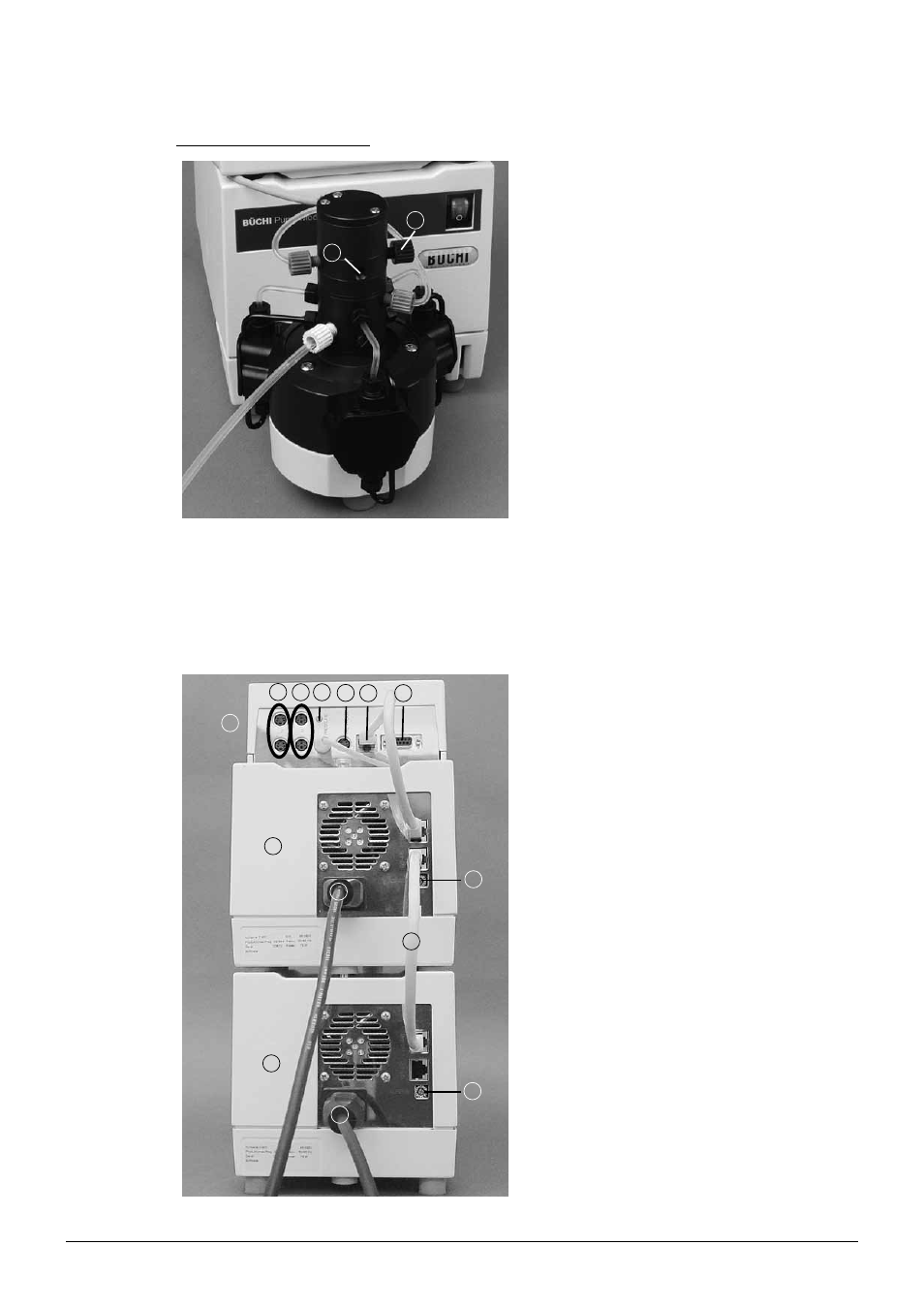

Fig. 5.13: Pump head with connected pressure tubing

5 .3 .4

Pump system 3: Pump Manager C-615 and 2 Pump Modules C-601 or C-605

NOTE

You can connect two pump modules to the pump manager if both modules are of the same type.

5

7

1

3 4

8

6

2

11

11

7

9

10

12

One pump module has the address selector switch

set to A (factory setting), the other has the selector

switch set to B.

Place the first pump module l on a level surface.

Make sure the address selector switch is set to B

j. If not, take the screwdriver and turn the small

white dot to B. Make sure the selector switch of

the second pump module l is set to A i. Place

the pump module on top, and press firmly from the

back, or place it next to the other. Connect both

pump modules to the power supply k.

A holding angle is located in the center back of the

pump manager b. Remove it.

There is a rail located at the bottom of the pump

manager. Slide it from the front to the end of the

stop on the pump module. Attach the holding

angle.

Connect the two pump modules l a to the pump

manager b by means of the cable RJ45 g.

c

LEVEL: Port for optional solvent level sensor

d VALVE: Port for optional solvent valve

e PRESSURE:

Port for level sensor

f TTL IN/OUT: TTL connection

h RS 232: Serial output signal

Fig. 5.14: Electrical installation