8 troubleshooting, 8 .1 malfunctions and their remedy – BUCHI Pump Module C-605 User Manual

Page 40

8 Troubleshooting

40

Pump Combinations Operation Manual, Version E

8 Troubleshooting

The following chapter describes how to resume operation of the instrument in the event of any minor

problem. It will list some possible occurrences, their probable cause and suggests how to remedy the

problem. The troubleshooting table below lists possible malfunctions and errors of the instrument and

describes operator enabled courses of action to correct some of tubing problems by him or herself.

The appropriate course of action is listed in the column “Corrective measure”.

The elimination of more complicated malfunctions or errors is usually performed by a BUCHI technical

engineer who has access to the official service manuals. In this case, please refer to your local BUCHI

customer service agent.

In the event of an error, the pump will stop and an acoustic alarm will sound. The acoustic alarm can

be stopped by pressing the START or STOP button once. If the error has been eliminated, the alarm

can be stopped by pressing the START or STOP button twice.

The beeping noise will not sound if the system has been externally stopped by the Fraction Collector

C-660 or the TTL input.

The Pump Module C-610 shows the error message on the display in the form “Exy” whereby “xy”

stands for the error number.

Error “01” of the pump module can either be confirmed with the START or the STOP button. When

the START button is pressed, the error message display disappears, and the pump restarts with the

current value. If the STOP button is pressed, the error message display disappears, and the current

value is shown, as usual. If the flow rate has still not been achieved, error “01” will be displayed again.

If the waste container is full or the connected Fraction Collector C-660 shows an error, the pump

will stop without displaying an error. The error message will be displayed on the fraction collector.

The pump cannot be switched on again until the cause has been eliminated and the error has been

confirmed at the fraction collector.

8 .1

Malfunctions and their remedy

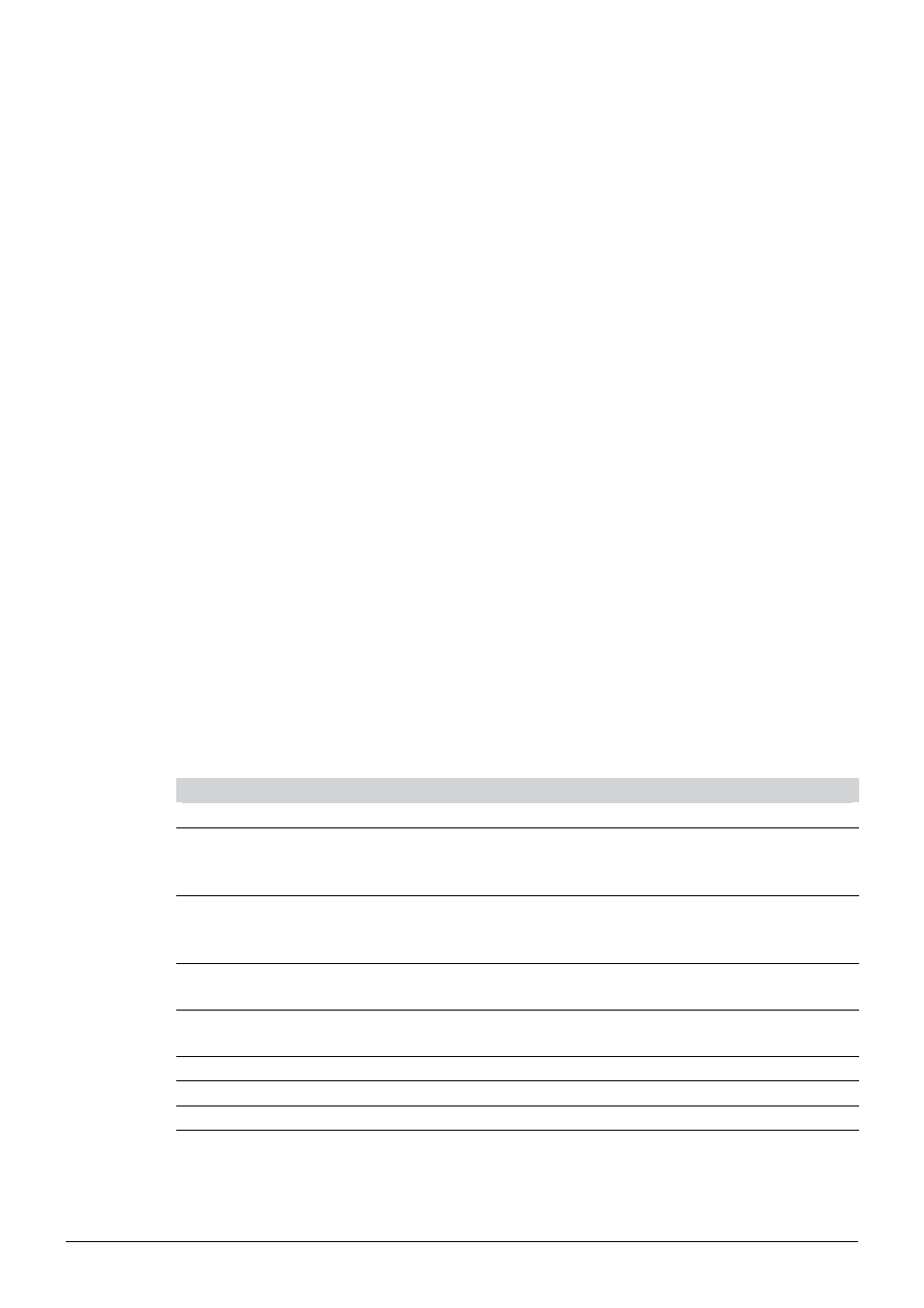

Table 8-1: Error messages of the Pump Controller C-610

Error number

Possible cause

Remedy

01

Pump cannot reach desired flow rate. The

pump electronics have switched off the pump,

since the pressure is too high.

Control backpressure

Contact the BUCHI Customer Service.

02

No connection to pump (timeout).

Check RJ 485 connections. Check main power.

Check switch + connections. Check selector

switch at the back side of pump module.

03

Check sum false or unintelligible response

from pump.

Contact the BUCHI customer service

04

Error while writing in the pump electronics

EEPROM.

Contact the BUCHI customer service

05

Temperature of pump electronics too high.

Contact the BUCHI customer service

06

Line voltage too high.

Contact the BUCHI customer service

07

Line voltage too low.

Contact the BUCHI customer service