8 help with faults, 1 faults, possible causes and remedies, 8help with faults – BUCHI Rotavapo R-100 User Manual

Page 42

8 | Help with faults

BÜCHI Labortechnik AG

42/60

Operation Manual Rotavapor® R100

8

Help with faults

8.1

Faults, possible causes and remedies

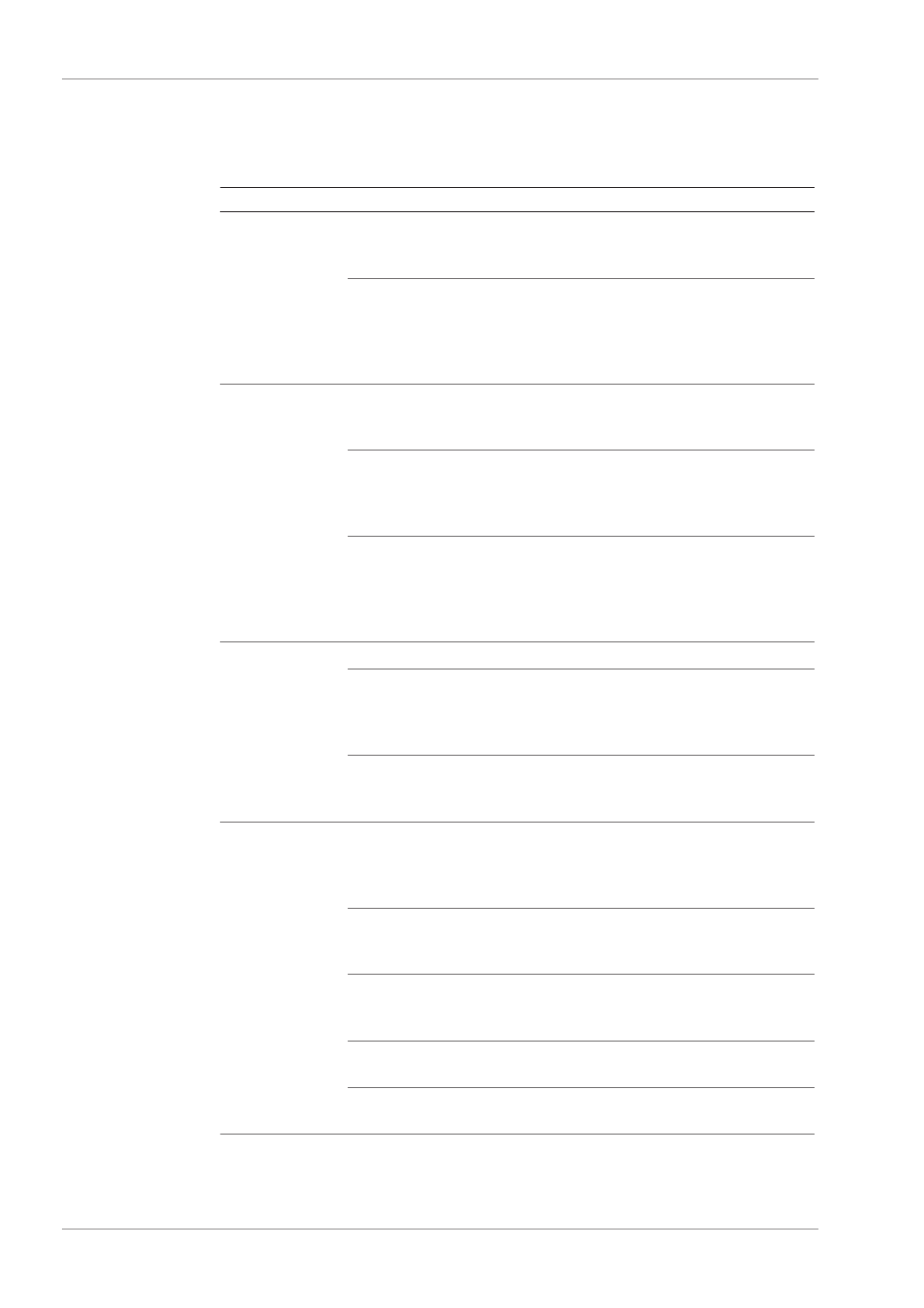

Fault

Possible cause

Remedy

Device does not

work

Device is not connected to

power supply

u

Check power supply (see

Chapter 5.6 "Electrical con

nections", page 25).

Fuse blown

u

Replace fuse (see Chapter

8.2.2 "Replacing the fuse",

page 45).

u

If fault recurs, contact

BUCHI Customer Service.

Heating bath

fails to heat up

Device is not connected to

power supply

u

Check power supply (see

Chapter 5.6 "Electrical con

nections", page 25).

High temperature cutout has

tripped

u

Reset the overheat safety

cutout (see Chapter 8.2.1

"Resetting overheat safety

cutout", page 44).

Fuse blown

u

Replace fuse (see Chapter

8.2.2 "Replacing the fuse",

page 45).

u

If fault recurs, contact

BUCHI Customer Service.

System leaking

Ground glass joints not greased

u

Grease ground glass joints.

Tubing leaking

u

Replace tubing (see Chap

ter 5.5 "Connecting the vac

uum and cooling media tub

ing", page 24).

Seal defective

u

Replace seal (see Chapter

7.3 "Checking seals", page

40).

Vacuum is not

achieved

Backevaporation from the re

ceiving flask

u

Empty the receiving flask

(see Chapter 6.3.2 "Remov

ing the receiving flask",

page 38).

Temperature difference be

tween evaporating flask and

condenser less than 20 °C

u

Increase cooling (see Chap

ter 6.2.2 "Adjusting distilla

tion conditions", page 34).

System leaking

u

Check system for leaks (see

Chapter 7.2 "Checking the

system for leaks", page 39).

Water pressure of glass filter

pump too low

u

Increase water flow (see

pump operating instructions).

Vacuum pump too weak

u

Use suitably dimensioned

vacuum pump.