7 cleaning and servicing, 1 inspecting and cleaning the vapor duct, 2 checking the system for leaks – BUCHI Rotavapo R-100 User Manual

Page 39: 7cleaning and servicing

BÜCHI Labortechnik AG

Cleaning and servicing | 7

Operation Manual Rotavapor® R100

39/60

7

Cleaning and servicing

NOTE

Users may only carry out the servicing and cleaning operations described in this sec

tion.

Any servicing and repair work which involves opening up the housing may only be

carried out by BUCHI service technicians.

u

Use only genuine BUCHI consumables and spare parts in order to ensure correct

operation of the device and preserve the warranty.

u

.

7.1

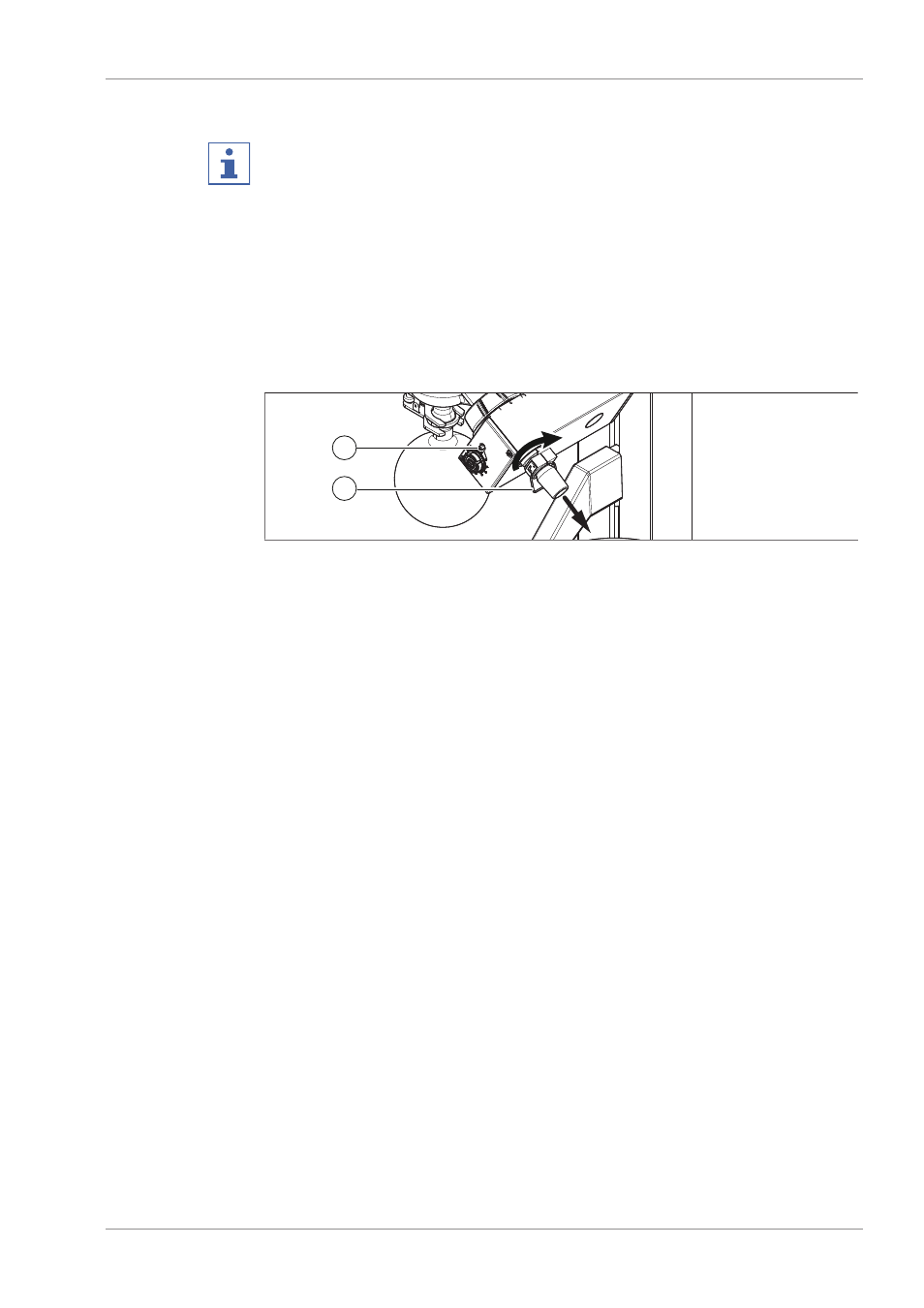

Inspecting and cleaning the vapor duct

1

2

u

Switch off the device.

u

Remove the evaporating flask (see Chapter 6.3.1 "Removing the evaporating

flask", page 37).

u

Press the lock release button (1) on the front of the rotary drive unit.

u

Firmly hold the vapor duct and turn the combiclip (2) clockwise until the vapor duct

is released.

u

Visually inspect the vapor duct for damage, wear marks and residues.

u

Clean the vapor duct with a paper towel and water or ethanol.

u

Refit the vapor duct (see Chapter 5.3 "Fitting the vapor duct and condenser", page

22).

7.2

Checking the system for leaks

Precondition:

R An external vacuum pump with a pressure gauge is connected.

u

Make sure that all flasks are fitted and the glass stopcock is closed.

u

Connect the vacuum pump and evacuate the R100 to a pressure of 50 mbar.

u

Switch off the vacuum pump. If necessary, disconnect the vacuum tubing so as to

exclude the vacuum pump as a possible source of a leak.

u

Check the pressure after one minute.

5 If the pressure has risen by less than 3 mbar after one minute, the system is air

tight.

If the system is not airtight:

u

Check all seals (see Chapter 7.3 "Checking seals", page 40).

u

Examine all tubing and replace if they are brittle or cracked.

u

Grease ground glass joints if necessary.