3 checking seals, 4 cleaning the condenser – BUCHI Rotavapo R-100 User Manual

Page 40

7 | Cleaning and servicing

BÜCHI Labortechnik AG

40/60

Operation Manual Rotavapor® R100

7.3

Checking seals

Seals are wear parts. They have to be regularly inspected, cleaned and, if necessary,

replaced. The life of a seal depends on much it is used and how well it is looked after.

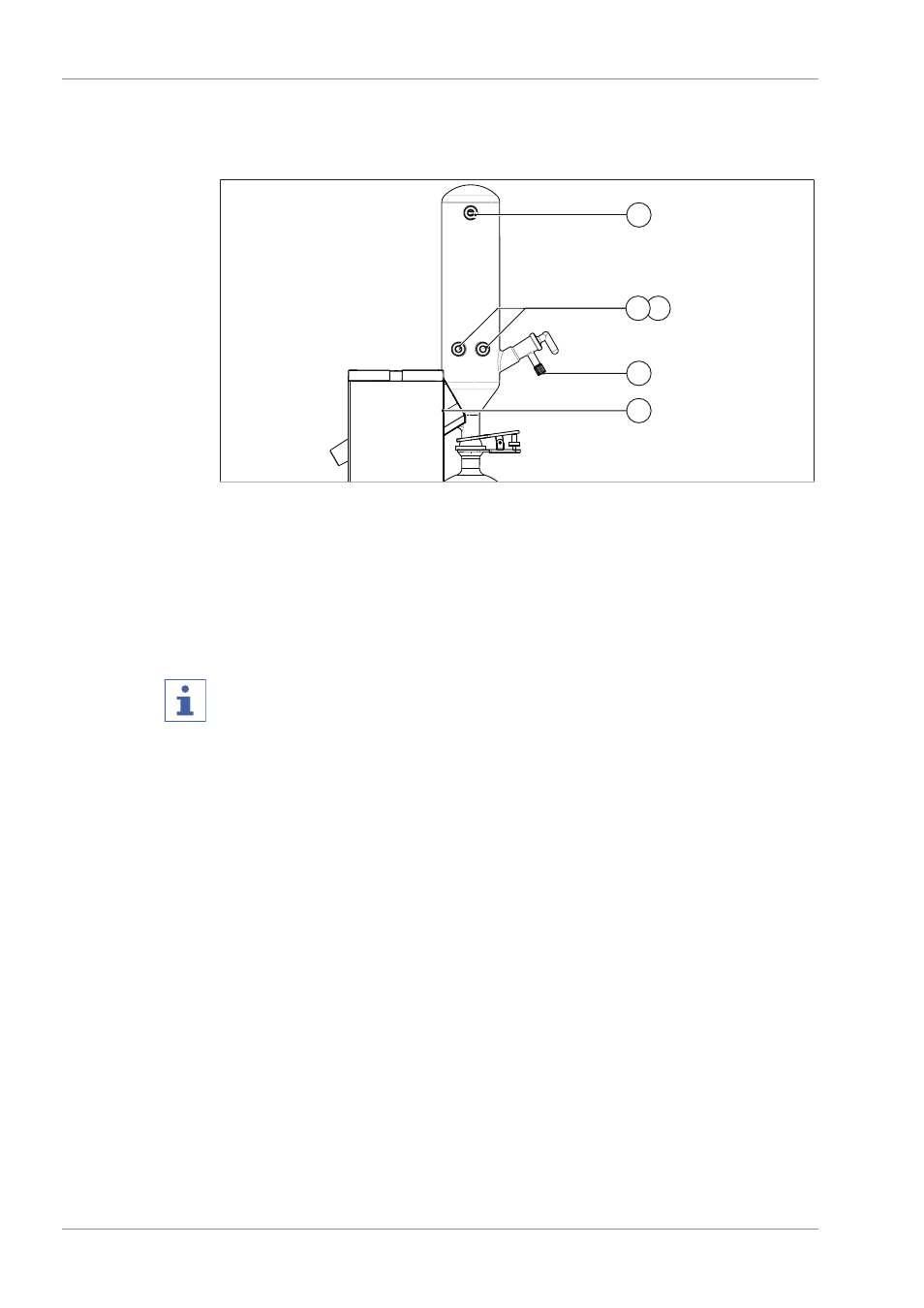

4

2

1

3

5

1 Vacuum connection seal

4 Feed tubing seal

2 Coolant seal

5 Vacuum gasket (not visible)

3 Coolant seal

u

Remove seals and inspect for damage and cracks.

u

Rinse intact seals in water or ethanol and dry with a soft cloth.

u

Replace damaged seals and check the corresponding glass contact faces for dam

age (e.g. wear marks).

NOTE

New PTFE seals require approx. 10 hours to achieve an optimum seal.

7.4

Cleaning the condenser

u

Using a wash bottle, squirt ethanol into the vacuum connection of the condenser

and rinse it out.

u

After rinsing allow the ethanol to drain out at the bottom.

u

Use an alkaline cleaning agent to remove stubborn dirt (e.g. algae).