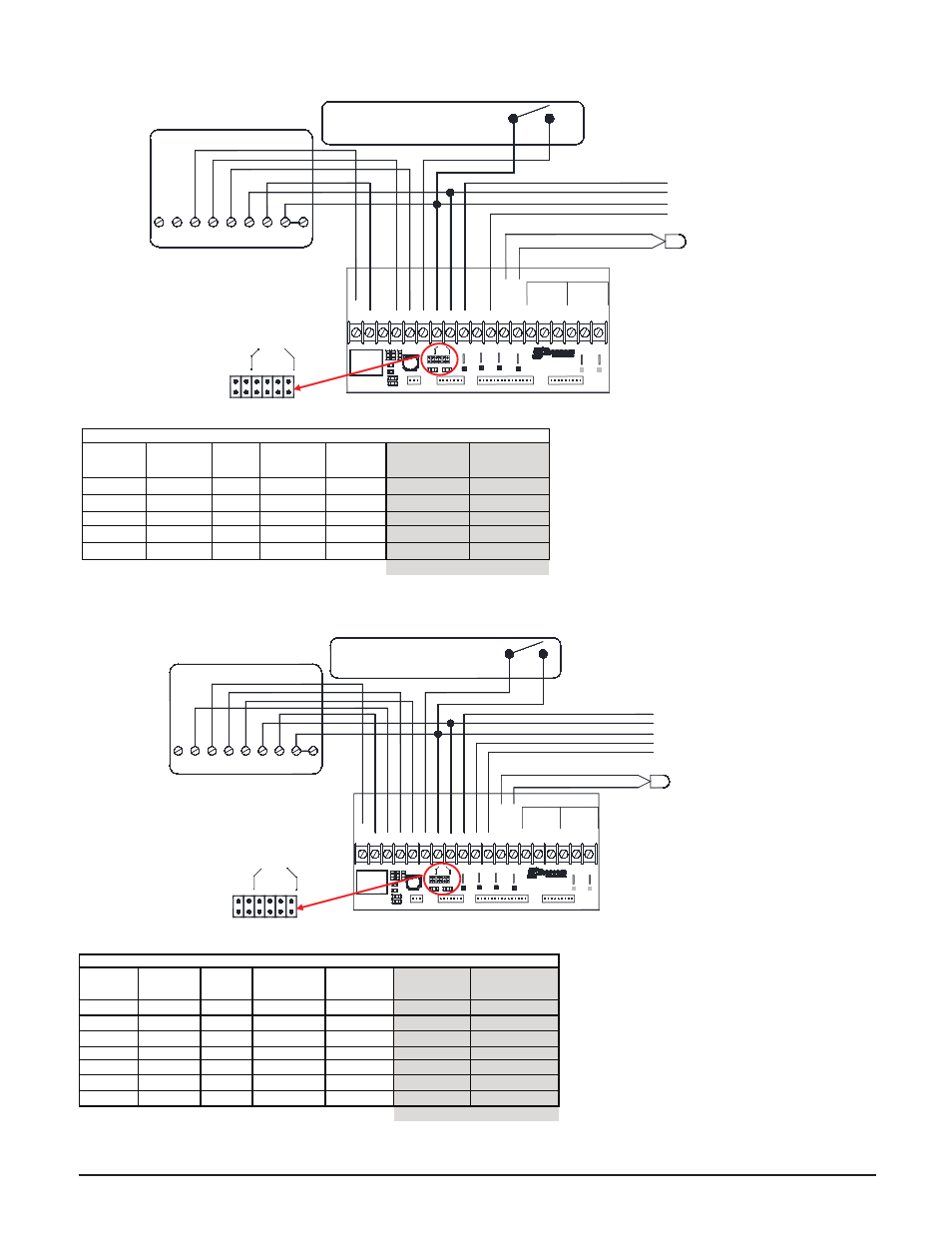

Two stage heat pump application figure 15, Single stage heat pump application figure 14, Comfort plus hydronic installation – Steffes 5140 Owner & Installers Manual User Manual

Page 19: W - not used, Outdoor sensor

The W/E Jumper must be removed

The Y1/Y2 Jumper must be removed

Inputs

Peak

P7

LV Circuit Board

Comfort Plus

To Control Board

P10

Fid 2

RLY1

D4

D6

R2

R1

P11

D3

D7

D5

W E

Y1 Y2

Water

A

ir

P6

D1

P5

Blower

J3

J1

J2

J4

D2

To Control Board

P3

C

Blower

Speed

A

B

J5

J6

C3

D

P4

P2

P1

O

W/

Y1

AUX

Y2 G

Outdoor

Outdoor

Y2

R

H/E

2

Y1

C

O

2

2

RP P

R

C

P8

P9

Aux.

COM

NC

AP

NO

Relay

Honeywell TH5320D

Aux

L Y2

G

C

O/B

Hydronic Heat Thermostat, Zone

Valve End Switch, or Pump Control

R

Y R

c

C - Low Voltage Common

Outdoor Sensor

O - Reversing Valve

R - Low Voltage Hot

To Heat Pump

Y1 - Compressor

Y2 - Compressor Stage 2

W - Not Used

H/E

R C

Outdoor

Outdoor

COM

NC

NO

W/

D6

RLY1

To Control Board

D4

Fid 2

Blower

To Control Board

A

ir

C3

P10

R1

R2

P11

D5 D7 D3

Water

Y1 Y2

W E

D2

J3

J2

J1

P5

D1

J4

P6

P4

Speed

Blower

J6

J5

C

B

A

D

P2

P3

Y1

AUX

O

G

Y2

Y1

2

Y2

2

2

O

C

R

Comfort Plus

LV Circuit Board

P7

W - Not Used

AP

P

RP

Peak

Aux.

Inputs

Relay

The Y1/Y2 Jumper must be installed

Honeywell TH5220D

Aux

E

L

C

G O/B

R

Y

R

c

Hydronic Heat Thermostat, Zone

Valve End Switch, or Pump Control

C - Low Voltage Common

R - Low Voltage Hot

O - Reversing Valve

Y - Compressor

To Heat Pump

Outdoor Sensor

The W/E Jumper must be removed

P9

P1

P8

Comfort Plus Hydronic

Installation

n

3.10

TWO STAGE HEAT PUMP APPLICATION

FIGURE 15

*

If multiple inputs are active, system will

display highest Heat Call values. "COOL"

overrides all inputs and stops all heating

operations.

** Systems built before 1/1/2011 are con-

fi gured for 50% airfl ow in Stage 1. For

more information, refer to Instruction

#1200601-High Speed Stage 1 Relay

Installation.

*** Thermostat must be programmed to

energize reversing valve for cooling. If

outdoor unit used requires the reversing

valve be energized for heating, see Con-

fi guration Menu on pages 3.14-3.15.

IMPORTANT

SINGLE STAGE HEAT PUMP APPLICATION

FIGURE 14

* If multiple inputs are active, system will

display highest Heat Call values. "COOL"

overrides all inputs and stops all heating

operations.

** Thermostat must be programmed to energize

reversing valve for cooling. If outdoor unit

used requires the reversing valve be ener-

gized for heating, see Confi guration Menu on

pages 3.14-3.15.

IMPORTANT

A

B

C

D

W / E

Y1 / Y2

J1

J2

J3

J4

J5

J6

Blower

Speed

A

B

C

D

W / E

Y1 / Y2

J1

J2

J3

J4

J5

J6

Blower

Speed

Single Stage Heat Pump with Auxiliary Heat / Single Stage Cool **

Thermostat

Stage

Thermostat

Output

Heat

Pump

Stage

ECM Board

Output to

Heat Pump*

% of

Selected

CFM

Heat Call

Status on

Digital Display*

Discharge Air

Temperature

Target

1

Y/G

1

R/Y1

2

100%

HC1

L048/C010

Aux

Aux/Y/G

1

R/Y1

2

100%

HC2

L049

Fan

G

0

R

400 cfm

HCF

N/A

Cool

Y/G/O

1

R/Y1

2

/O

2

100%

COOL

N/A

Hydronic

Varies

N/A

N/A

OFF

HC3

N/A

Contractor Use Only

Two Stage Heat Pump with Auxiliary Heat / Two Stage Cool ***

Thermostat

Stage

Thermostat

Output

Heat

Pump

Stage

ECM Board

Output to Heat

Pump*

% of Selected

CFM

Heat Call

Status on

Digital Display*

Discharge Air

Temperature

Target

1

Y/G

1

R/Y1

2

50% or 70%**

HC1

L048/C010

2

Y/Y2/G

2

R/Y1

2

/Y2

2

100%

HC1

L048/C010

3

Aux/Y/Y2/G

2

R/Y1

2

/Y2

2

100%

HC2

L049

Fan

G

0

R

400 cfm

HCF

N/A

Cool 1

Y/G/O

1

R/Y1

2

/O

2

50% or 70%**

COOL

N/A

Cool 2

Y/Y2/G/O

2

R/Y1

2

/Y2

2

/O

2

100%

COOL

N/A

Hydronic

Varies

N/A

N/A

OFF

HC3

N/A

Contractor Use Only