Magnetic fader rail cleaning – Rane TTM 57SL Manual for Serato Scratch Live 2.44 User Manual

Page 49

RANE TTM 57SL MIXER FOR SERATO SCRATCH LIVE • OPERATOR’S MANUAL 2.4.4

49

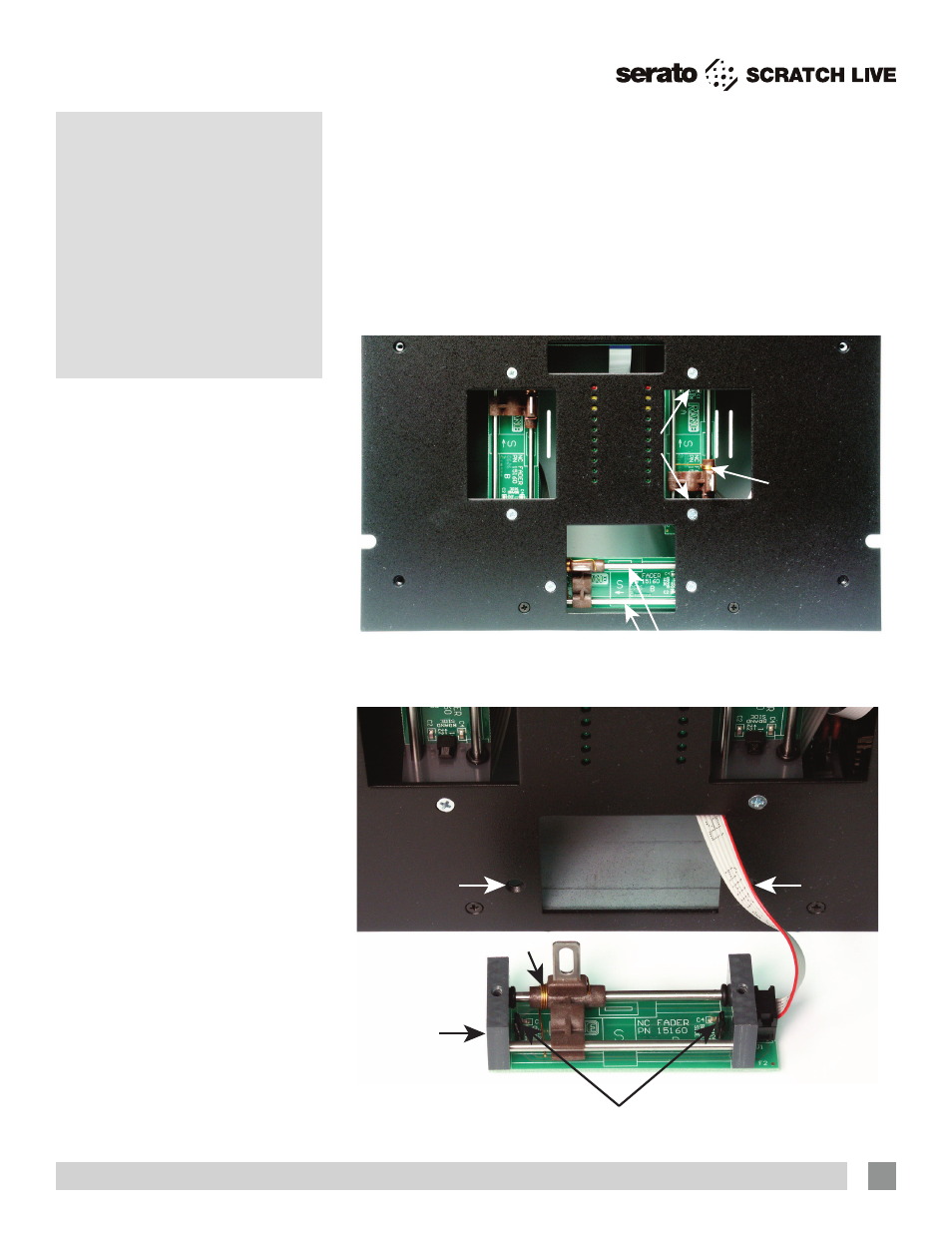

A. Move the carrier all the way to one

side.

B. Use a soft lint-free cloth to wipe off the

rails.

C. Add a drop of silicone lubricant (or

quick spray from aerosol) to the center

of each rail.

D. Move the carrier back and forth to

distribute lubricant.

E. Do not bend the torsion spring or touch

the sensors.

For more effective cleaning and

lubrication, follow the directions below:

1. Required Tool: #1 Philips screwdriver.

2. Disconnect the power.

3. Remove knobs from controls covered

by the Lexan faceplate.

4. Remove the four, 4-40 screws attaching

the Lexan faceplate.

5. Remove the Lexan faceplate. See the

picture and instructions below. The

rails of the fader are now accessible for

normal cleaning and lubrication.

6. Remove fader from mixer if more

thorough cleaning is required.

7. NOTE: Do not disturb the position of

the small sensors at each end of the

Fader. If you do, make sure the parts are

standing straight before reinstalling.

8. NOTE: In order to achieve the highest

possible accuracy, each magnetic fader

is factory calibrated for the location in

which it was shipped. If you remove the

faders for cleaning, make sure you mark

them. This helps you to put them back

in the correct location.

Magnetic

Fader Rail

Cleaning

Torsion

Spring

Sensors

Rails

Torsion spring

Sensors

Remove ribbon

Remove

#4 screw

Remove

#4 screw

Mark location before

disconnecting ribbon:

PGM 1

PGM 2

XFADER

9. Remove the fader by removing the two

#4 screws securing it. Then disconnect

the ribbon cable.

10. Sugary liquids spilled into a fader may

be removed by thoroughly rinsing the

part in hot water. Make sure the part

is clean and dry before lubricating or

reinstalling.

11. Removal of grease or other stubborn

debris may require alcohol or contact

cleaner. Make sure the part is clean and

dry before lubricating or reinstalling.

12. To reassemble, reverse the

disassembly procedure.

13. Problems? Contact Rane Corporation

customer service at 425-355-6000 or

email us at [email protected].