WEATHER GUARD Model 173-5-01 Pork Chop Box, Aluminum, Passenger Side, 3.4 cu ft User Manual

Page 3

FEATURE OPERATION

LOCK SYSTEM

The WEATHER GUARD® Extreme Protection™ Lock is designed to provide maximum security, while providing ease of

use and years of reliable service. When in the locked mode, the button remains retracted in a tamper-resistant position.

When the button is pressed in the unlock mode, the latch is activated and the cover opens.

LATCH SYSTEM

The WEATHER GUARD® Latch System utilizes an automotive grade latch in conjunction with a high strength latch striker

to ensure maximum security. The WEATHER GUARD® Latch System is designed to open with a single touch of the button,

and close securely. Expect years of reliable service from the WEATHER GUARD® Latch System with only minimal mainte-

nance: Bi-annually lubricate latch pivot points with white grease. If latch striker is accidentally knocked out of alignment,

simply use a mallet to re-align.

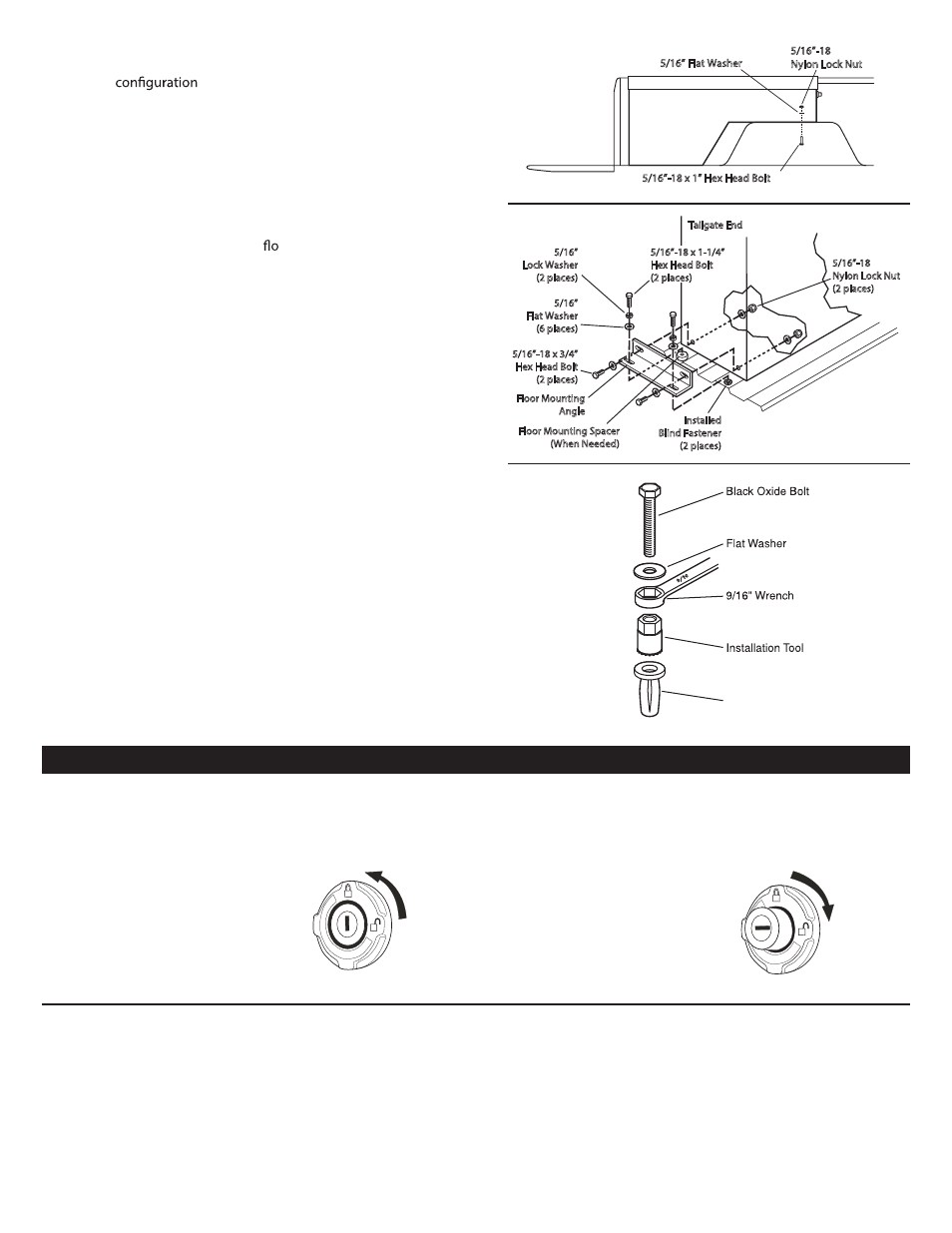

5/16” Flat Washer

5/16”-18

Nylon Lock Nut

5/16”-18 x 1” Hex Head Bolt

5/16”-18

Nylon Lock Nut

(2 places)

5/16”

Lock Washer

(2 places)

5/16”

Flat Washer

(6 places)

5/16”-18 x 3/4”

Hex Head Bolt

(2 places)

Floor Mounting

Angle

Floor Mounting Spacer

(When Needed)

Installed

Blind Fastener

(2 places)

Tailgate End

5/16”-18 x 1-1/4”

Hex Head Bolt

(2 places)

3

Figure 4

Figure 5

Figure 6

Alternate Mounting Method Figure 4

Use if truck

allows box to rest directly on wheel well.

• Mark, center punch and drill 3/16” hole in bottom of box and top

of wheel well as shown in Fig. 4.

• Re-drill holes with 3/8” drill bit.

• Install bolt per Fig. 4.

Note: Install bolts from underside when fastening Mounting Angle to

wheel well.

Step 4: ATTACH FLOOR MOUNTING ANGLE (see Figure 5)

• Place Floor Mounting Angle on or, centered behind the box.

• Mark, center punch and drill all four holes with 3/16” drill bit.

Note: If holes in Floor Mounting Angle are not positioned above rib,

use Floor Mounting Spacers provided.

• Re-drill holes in box with a 3/8” drill bit.

• Re-drill holes in truck bed with 1/2” drill bit.

• Install Blind Hole Fasteners in truck bed per Fig. 6

• Install Floor Mounting Angle per Fig. 5.

BLIND FASTENER INSALLATION

Note: Make sure there is enough hole depth before installing the

Blind Fastener.

Note: Black Oxide Bolt, Flat Washer, and Installation Tool are only

used to install Blind Fasteners.

• Install Blind Fastener using Fig. 6 as a guide.

• Place a drop of oil on black oxide bolt for lubrication.

• Insert Blind Fastener in the hole.

• Hold the “Installation Tool” with a 9/16” wrench while turning the

“Black Oxide Bolt” with a 1/2” wrench until fully seated.

• Turning “Black Oxide Bolt” will be hard until fastener “bulbs” out.

• When Blind Fastener is fully seated, continue with installation.

LOCK

Turn key counterclockwise to

locked position as indicated on

lock bezel. When the button is now

pressed, it will stay in the retracted

or tamper-resistant position until

unlocked.

UN-LOCKED

Turn key clockwise to unlock posi-

tion as indicated on the lock bezel.

Button will pop out and is now

ready to release the latches when

pressed.

Blind Fastener

- Model 173-0-01 Pork Chop Box, Aluminum, Passenger Side, 3.4 cu ft Model 172-5-01 Pork Chop Box, Aluminum, Driver Side, 3.4 cu ft Model 172-0-01 Pork Chop Box, Aluminum, Driver Side, 3.4 cu ft Model 171-5-01 Pork Chop Box, Aluminum, Passenger Side, 3.4 cu ft Model 171-0-01 Pork Chop Box, Aluminum, Passenger Side, 2.1 cu ft Model 170-5-01 Pork Chop Box, Aluminum, Driver Side, 2.1 cu ft Model 170-0-01 Pork Chop Box, Aluminum, Driver Side, 2.1 cu ft Model 166-3-01 Super Lo-Side Box, Steel, 9.2 cu ft Model 165-3-01 Lo-Side Box, Steel, Long, 6.2 cu ft Model 164-5-01 Lo-Side Box, Aluminum, Long, 6.4 cu ft Model 164-0-01 Lo-Side Box, Aluminum, Long, 6.4 cu ft Model 163-3-01 Pork Chop Box, Steel, Passenger Side, 3.4 cu ft Model 162-3-01 Pork Chop Box, Steel, Driver Side, 3.4 cu ft Model 161-3-01 Pork Chop Box, Steel, Passenger Side, Standard, 2.1 cu ft Model 160-3-01 Pork Chop Box, Steel, Driver Side, 2.1 cu ft