Step 6 — install accessories, Step 7 — complete electrical connections – Carrier 38AU User Manual

Page 14

14

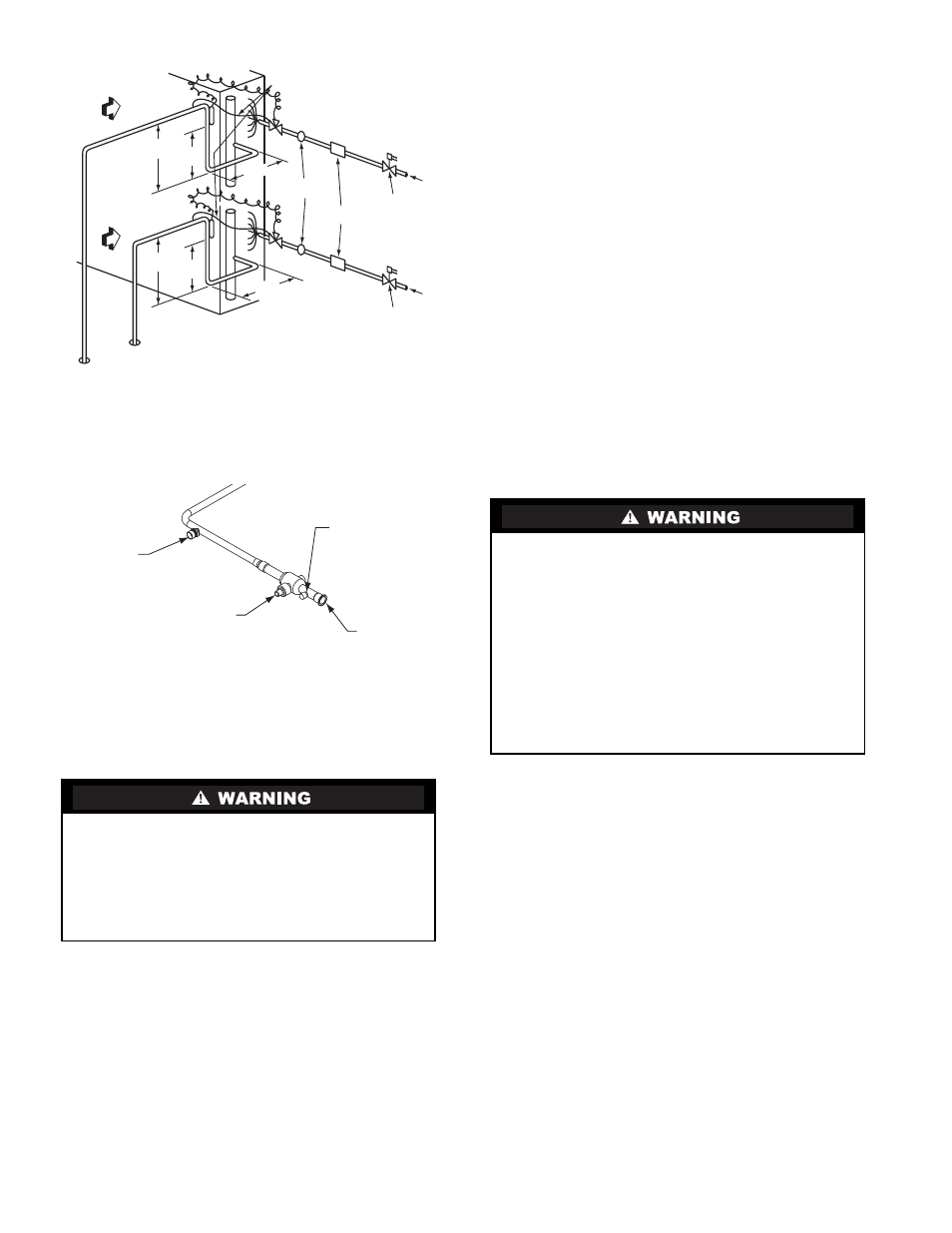

Fig. 8 — Location of Sight Glass(es) and Filter Driers

Typical 38AUD Systems

Fig. 9 — Typical Piping Connection Assembly

EVACUATION/DEHYDRATION — Evacuate and dehydrate

the connected refrigeration system(s) (excluding the 38AU

unit) to 500 microns using a two-stage vacuum pump attached

to the service ports outside the 38AU service valves, following

description in GTAC II, Module 4, System Dehydration.

PRELIMINARY CHARGE — Before starting the unit, charge

R-410A liquid refrigerant into the high side of each 38AU

circuit through the liquid service valve(s). The amount of

refrigerant added must be at least 80% of the operating charge

listed in Tables 5 or 6 for LINEAR line length LESS the

factory charge quantity (if factory shipping charge has not been

removed). See example below.

Allow high and low side pressures to equalize. If pressures do

not equalize readily, charge R-410A vapor (using special

service manifold with expansion device) into the suction line

service port for the low side of system to assure charge in the

evaporator. Refer to GTAC II, Module 5, Charging, Recover,

Recycling, and Reclamation for liquid charging procedures.

Example:

38AUZ*08

60-ft (18.3 m) linear line length

Equivalent line length 90-ft (27.4 m)

Liquid Lift: 20-ft (6.1 m)

Select line sizes from Table 5 (38AUZ):

Liquid

1

/

2

in

Suction 1-

1

/

8

in.

Charge 12.9 lbs (at 75-ft linear length)

80% of Operating Charge:

0.80 x 12.9 = 10.3 lbs

Factory Shipping Charge: 4.9 lbs

Field-charge quantity: 10.3 lbs – 4.9 lbs = 5.4 lbs

For applications with linear line lengths greater than 100 ft

(30.5 m), contact your local Carrier representative.

Step 6 — Install Accessories

Accessories requiring modifications to unit wiring should be

completed now. These accessories may include Winter Start

controls, Low Ambient controls, phase monitor, Compressor

LOCout. Refer to the instructions shipped with the accessory.

Step 7 — Complete Electrical Connections

NOTE: Check all factory and field electrical connections

for tightness. Field-supplied wiring shall conform with the

limitations of 33°C (63°F) rise.

Field Power Supply —

If equipped with optional Powered Convenience Outlet: The

power source leads to the convenience outlet's transformer pri-

mary are not factory connected. Installer must connect these

leads according to required operation of the convenience outlet.

If an always-energized convenience outlet operation is desired,

connect the source leads to the line side of the unit-mounted

disconnect. (Check with local codes to ensure this method is

acceptable in your area.) If a de-energize via unit disconnect

switch operation of the convenience outlet is desired, connect

the source leads to the load side of the unit disconnect. On a

unit without a unit-mounted disconnect, connect the source

leads to compressor contactor C and indoor fan contactor IFC

pressure lugs with unit field power leads.

All units are factory wired for the voltage shown on the name-

plate. Refer to unit label diagram for additional information.

Field power wires are connected to the unit at line-side pres-

sure lugs on compressor contactor C and TB1 (see wiring dia-

gram label for control box component arrangement) or at facto-

ry-installed option non-fused disconnect switch. Use copper

conductors only.

UNIT OPERATION AND SAFETY HAZARD

Failure to follow this warning could cause personal injury,

death and/or equipment damage.

Puron® (R-410A) refrigerant systems operate at higher

pressures than standard R-22 systems. Do not use R-22

service equipment or components on Puron refrigerant

equipment.

INDOOR

COIL CKT 2

AIRFLOW

SUCTION

CIRCUIT B

SUCTION

CIRCUIT A

AIRFLOW

15 DIAMS

MIN

10

DIAMS

8 DIAMS

MIN

TXV

SENSING

BULB

EQUALIZER LINE

SIGHT

GLASSES

TXV

CKT B

FILTER

DRIERS

DROP CONTROL

SOLENOID VALVE

CIRCUIT B

FLOW

DROP CONTROL

SOLENOID VALVE

CIRCUIT A

FLOW

TXV

SENSING

BULB

TXV

CKT A

8 DIAMS

MIN

15 DIAMS

MIN

10

DIAMS

Dual Circuit Coil Piping Configuration

For two circuit condensing units

LEGEND

TXV — Thermostatic Expansion Valve

Factory

High-Flow

Access Port

Service Valve

with Stem Cap

Field Service

Access Port

(Schrader core)

Sweat

Connection

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Do not use gas piping as an electrical ground. Unit cabinet

must have an uninterrupted, unbroken electrical ground to

minimize the possibility of personal injury if an electrical

fault should occur. This ground may consist of electrical

wire connected to unit ground lug in control compartment,

or conduit approved for electrical ground when installed in

accordance with local electrical codes or in absence of

local codes, it is recommended that the U.S.A. standard

ANSI/NFPA 70, National Electrical Code (NEC), be

followed.