Carrier 38AU User Manual

Page 13

13

Table 9 — Refrigerant Specialities Part Numbers.

Refer to Table 9 for recommendations on refrigeration

specialties.

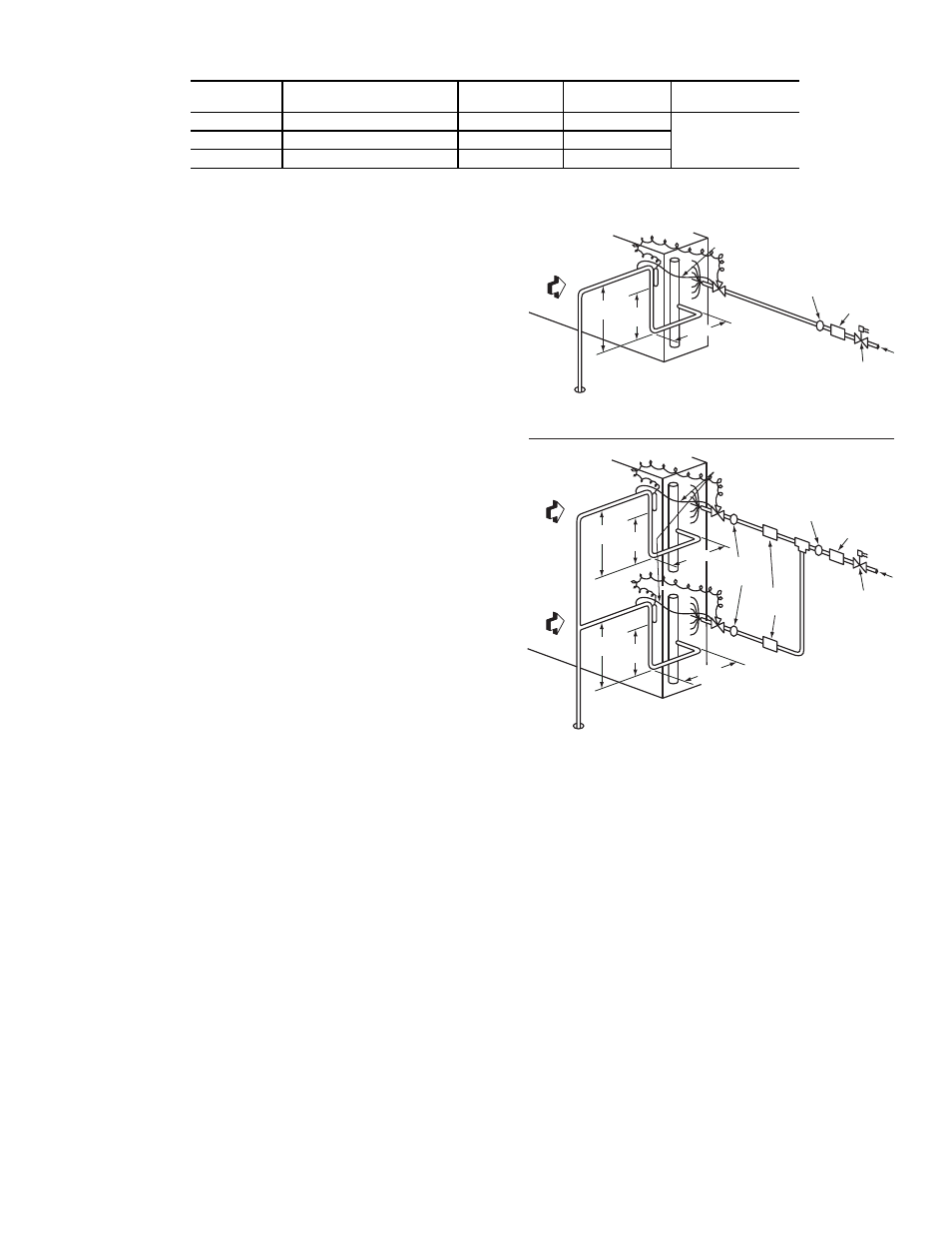

In some applications, depending on space and convenience re-

quirements, it may be desirable to install 2 filter driers and sight

glasses in a single circuit application. One filter drier and sight

glass may be installed at A locations in Fig. 7, or 2 filter driers

and sight glasses may be installed at B locations.

Select the filter drier for maximum unit capacity and minimum

pressure drop. Complete the refrigerant piping from the indoor

unit to the outdoor unit before opening the liquid and suction

lines at the outdoor unit.

INSTALL LIQUID LINE SOLENOID VALVE —

It is recommended that a solenoid valve be placed in the main

liquid line (see Fig. 7) between the condensing unit and the

evaporator coil. Locate the solenoid valve at the outlet end of

the liquid line, near the evaporator coil connections, with flow

direction arrow pointed at the evaporator coil. Refer to Table 9.

(A liquid line solenoid valve is required when the liquid line

length exceeds 23 m [75 ft].) This valve prevents refrigerant

migration (which causes oil dilution) to the compressor during

the off cycle, at low outdoor ambient temperatures. Wire the

solenoid in parallel with the compressor contactor coil (see

Fig. 7). This means of electrical control is referred to as sole-

noid drop control.

CAPACITY CONTROL LIQUID LINE SOLENOID VALVE

Evaporator capacity control via liquid solenoid valve is not rec-

ommended for use with 38AU models.

MAKE PIPING CONNECTIONS — Piping connections at

the 38AU unit are ball valves with stub tube extensions. Do not

open the unit service valves until all interconnecting tube braz-

ing as been completed.

The stub tube connections include ¼-in SAE service fittings

with Schrader valve cores (see Fig. 9). Before making any

brazed connections to the unit service valves, remove both

Schrader valve caps and cores and save for re-installation. Con-

nect a source for nitrogen to one of these service fittings during

tube brazing to prevent the formation of copper oxides inside

the tubes at brazed joints.

When connecting the field tubing to the 38AU service valves,

wrap the valves in wet rags to prevent overheating

Pressure-test all joints from outdoor unit connections over to

the evaporator coil, using nitrogen as pressure and with soap-

and-bubbles.

When pressure-testing is completed, remove the nitrogen

source at the outdoor unit service valves and re-install the two

Schrader valve cores. Torque the cores to 23-34 N-cm

(2-3 in-lbs).

Fig. 7 — Location of Sight Glass(es) and Filter Driers

Typical 38AUZ Systems

LIQUID LINE

SIZE (in.)

LIQUID LINE

SOLENOID VALVE (LLSV)

LLSV

COIL

SIGHT

GLASS

FILTER

DRIER

3

/

8

ALC-066208

AMG-24/50-60

HMI-1TT3

Provided with unit

See Table 8

1

/

2

ALC-066209

AMG-24/50-60

HMI-1TT4

5

/

8

ALC-066212

AMG-24/50-60

HMI-1TT5

38AUD units require TWO sets of parts.

INDOOR

COIL CKT 2

AIRFLOW

INDOOR

COIL CKT 1

AIRFLOW

15 DIAMS

MIN

10

DIAMS

8 DIAMS

MIN

TXV

SENSING

BULB

EQUALIZER LINE

SIGHT GLASS

A LOCATION

SIGHT

GLASSES

B LOCATION

TXV

CKT 2

FILTER DRIER

A LOCATION

FILTER

DRIERS

B LOCATION

DROP

CONTROL

SOLENOID

VALVE

FLOW

TXV

SENSING

BULB

TXV

CKT 1

8 DIAMS

MIN

15 DIAMS

MIN

10

DIAMS

Single Circuit Coil Piping Configuration

For single compressor condensing units

Dual Circuit Coil Piping Configuration

For single compressor condensing units

15 DIAMS

MIN

10

DIAMS

8 DIAMS

MIN

INDOOR

COIL CKT

AIRFLOW

TXV

SENSING

BULB

EQUALIZER LINE

SIGHT GLASS

A LOCATION

TXV

FILTER DRIER

A LOCATION

DROP

CONTROL

SOLENOID

VALVE

FLOW

LEGEND

TXV — Thermostatic Expansion Valve