Alarm codes, Cpsm (customer preference selection mode) – Vintage Cellars Platinum MIni Split Tech Manual User Manual

Page 35

www.whisperkool.com | Page 33

Alarm

The Alarm symbol is shown and a audible buzzer will sound when the unit encounters an issue that

needs attention, the displayed alarm codes are explained below. To silence the buzzer press any but-

ton, the alarm code will remain displayed until corrected.

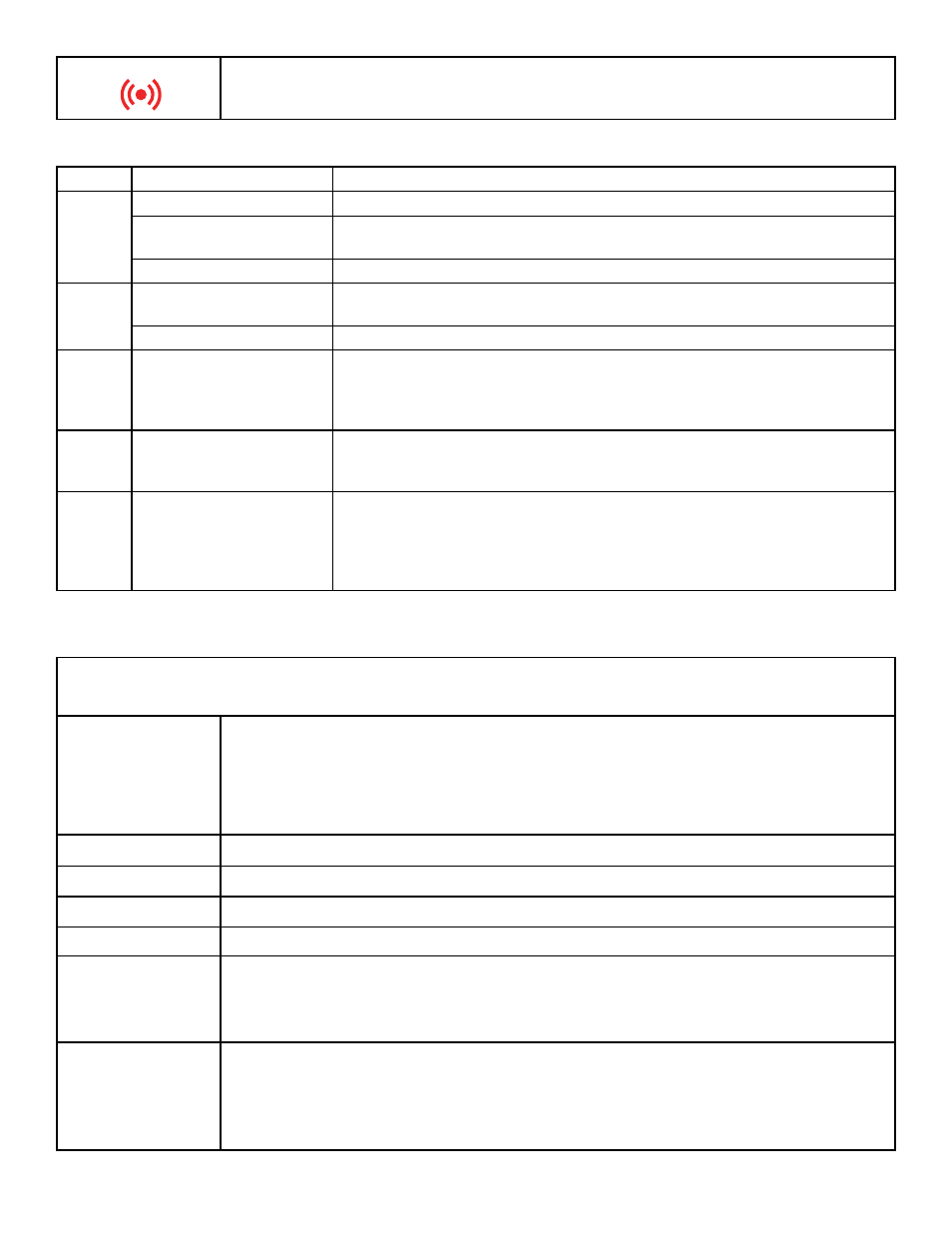

Alarm Codes

Message

Cause

Solution

“E1”

Bottle Probe is Unplugged

Attach Bottle Probe to Unit.

Faulty Bottle Probe

Connection

1. Check Bottle Probe attachment at circular connector.

2. Check Bottle Probe connection at the back of controller.

Defective Bottle Probe

Replace the Bottle Probe.

“E2”

Faulty Evaporator Probe

Connection

Check Evaporator Probe connection at the back of controller.

Defective Evaporator Probe

Replace the Evaporator Probe.

“AH1”

The bottle probe is sensing a

temperature that is 8° above

the set point

1. Allow time for the wine to reach the desired temperature.

2. Make sure all windows and doors are closed and have a proper seal.

3. Follow the procedures in the pre-installation instructions to test the unit for proper

cooling.

“AL1”

The bottle probe is sensing a

temperature that is 8° below

the set point

1. Make sure unit is not in cooling mode. (the snowflake symbol will not be lit)

2. Add heat to the room until the wine reaches the desired temperature.

“Ad3”

Anti-frost ended on time-out 1. Check the evaporator coil for ice buildup. Unplug the unit and allow coil to thaw

before re-starting.

2. Make sure the room to which the unit is exhausting is not less than 60°.

3. If unit continues to go into continuous anti-frost cycles (every 5 minutes), call cus-

tomer service for more troubleshooting information.

CPSM (Customer Preference Selection Mode)

Press and hold the set button for approximately 5 seconds to enter the CPSM menu.

“Fdc” will be displayed on the screen. Use the down arrow to access the following parameters.

Fdc

Humidity Management/

Enhancement

This parameter is set to 1 from the factory which should provide adequate relative humidity for the

cellar. An increase in this parameter will increase the Humidity Enhancement (%RH). This parameter

should not be adjusted below 1. Adjustments should be made in increments of 5, with a maximum of

15 and a minimum of 1. After any adjustment to Humidity Enhancement you should wait a minimum

of three days before making any additional adjustments. This will allow the cellar sufficient time to

acclimate to the new setting.

PA2 No adjustable settings in this parameter.

tab No adjustable settings in this parameter.

Rel No adjustable settings in this parameter.

loc Change this parameter from “n” to “y” to lock the keyboard from changes to the set point.

ddd

Select one of these numbers to display your preference:

0 = Set Point

1 = Bottle Probe Temperature

2 = Evaporator Probe Temperature

“CA1” Use this parameter to calibrate the bottle probe to a known temperature. This parameter can be ad-

justed between -12

°F and

12

°F.

Example: Bottle temperature reading = 58°F

Known temperature reading = 55°F

CA1 parameter setting to match known temperature = -3