2 bench scale adjustments, 3 clamshell installation, Bench scale adjustments – Rice Lake IQ plus 2100SL Digital Bench Scale User Manual

Page 31: Clamshell installation

27

6.6.2

Bench Scale Adjustments

The RL2100 bench scale uses a number of scre ws to

provide overload and underload protection for the load

cell. These protection screws are all set at the f actory

before shipment; use the follo wing information to

verify and reset protection screws.

Figure 6-10. RL2100 Protection Screw Adjustments

•

Lift-up Protection Screws

Set lift-up protection screw height to 0.06 in (1.52

mm).

•

Overload Protection Set Screw

Elevate the scale base to allow sufficient clearance

to adjust the set scre w, then center a load equal to

125% of scale capacity on the platter . Use a he x

wrench to advance the set screw until it touches the

load cell, then back of f 1/6 of a turn. Verify

calibration, then add a drop of non-permanent

thread adhesive (such as

LOCTITE

®

) to prevent the

set screw from vibrating loose.

•

Corner Overload Protection Screws

The correct height of the corner o

verload

protection screws depends on the scale capacity .

Adjust the four scre ws to the heights sho wn in

6.6.3

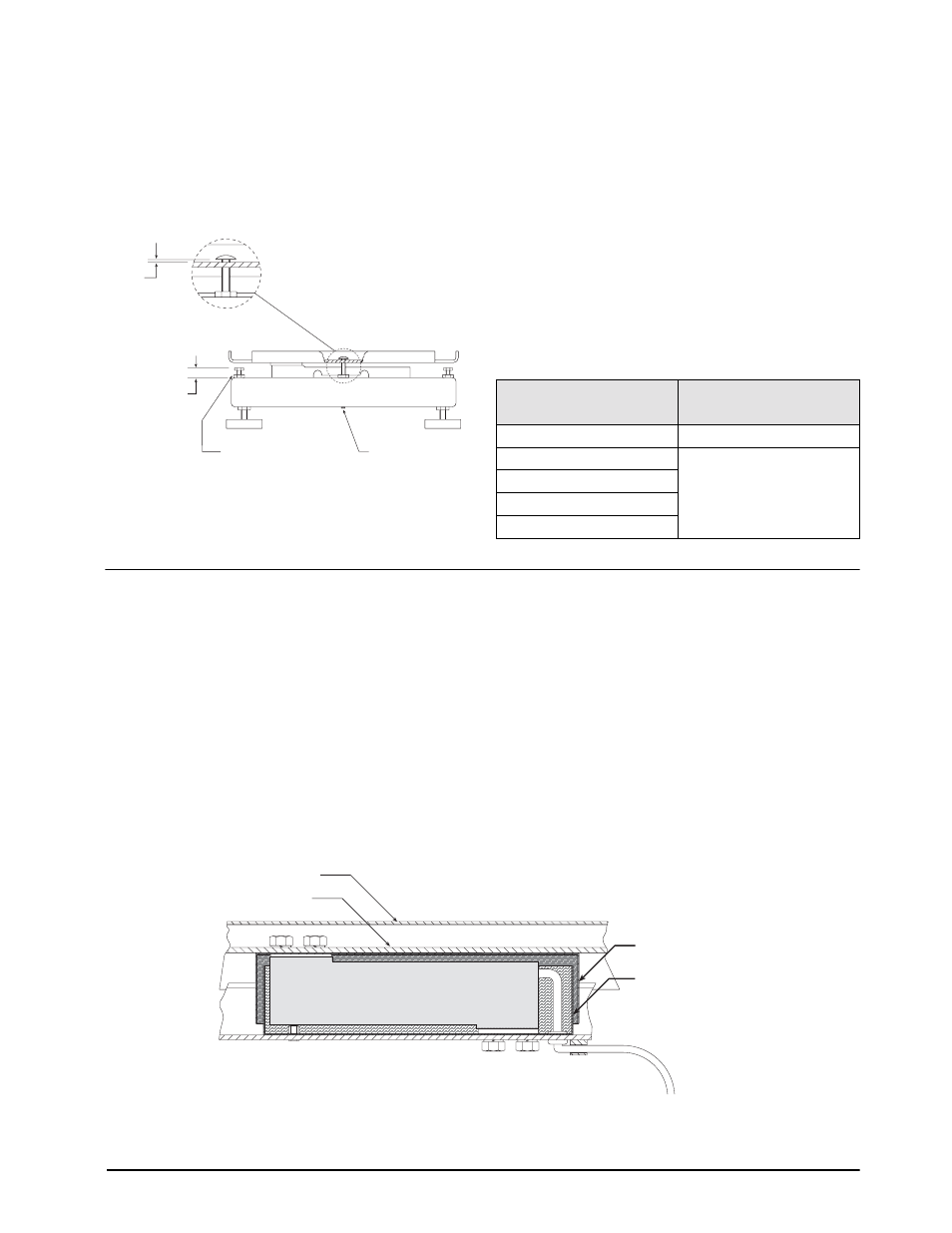

Clamshell Installation

Protective stainless steel clamshells are a vailable as an

option for all RL2100 bench scales. Clamshells are

pre-drilled for load cell scre ws, overload screw, and

cables. Existing load cell shims are reinstalled inside

the clamshells.

To install the clamshell, do the following:

1. Remove platter, spider plate, and load cell

using the procedure described in Section 6.6.1

2. Install lower clamshell in base. Route load cell

cable through lower clamshell and grommet.,

then reinstall lower shim and load cell so that

no part of the load cell touches the clamshell

enclosure. Replace lower load cell screws and

lockwashers. Torque to 80 in-lb (9.0 N-m).

3. Install upper clamshell, ensuring clearance on

all sides to pre vent binding against the lower

clamshell. Reinstall upper shim, spider plate,

lockwashers, and upper load cell scre

ws.

Torque screws to 80 in-lb (9.0 N-m).

4. Replace scale platter. Ensure that scale is level.

5. Readjust lift-up protection screws and overload

protection set screw on bottom of scale base as

described under Section 6.6.2.

6. Connect load cell cable to indicator . Power-up

indicator and recalibrate scale.

Figure 6-11. Clamshell Installation

0.06 in

D

Corner overload

protection screws (4)

Lift-up protection screws (2)

Overload protection

set screw

Model (Capacity)

Corner Overload Protection

Screw Height (D)

5 lb (2.5 Kg)

0.56 in (142 mm)

10 lb (5 Kg)

0.50 in (127 mm)

25 lb (10 Kg)

50 lb (25 Kg)

100 lb (50 Kg)

Table 6-4. Corner Protection Screw Height

Upper Clamshell

Lower Clamshell

Spider Plate

Platter

Load Cell