Gasket inspection – Rice Lake Retail Scales - MajorSlice 350A User Manual

Page 28

24

9. Use the lifting mechanism lever (#21) to clean the counter under the slicer then return the lever to its home

position.

10.Reassemble the slicer for normal operation once it has been cleaned.

How to Clean The Sharpener

If sharpening is required, sharpen the knife after cleaning product from the machine and knife. See sharpening

instructions, Section 5.3 on page 25.

Clean with a sanitizer concentration that complies with section 4-501.114 of the Manual and Mechanical

Warewashing Equipment, Chemical Sanitization-temperature, Ph, Concentration and Hardness of the FDA Food

Code.

The sharpener assembly may be submerged in warm soapy water and the stones can be cleaned with a

brush. Then rinse and allow to air dry before using

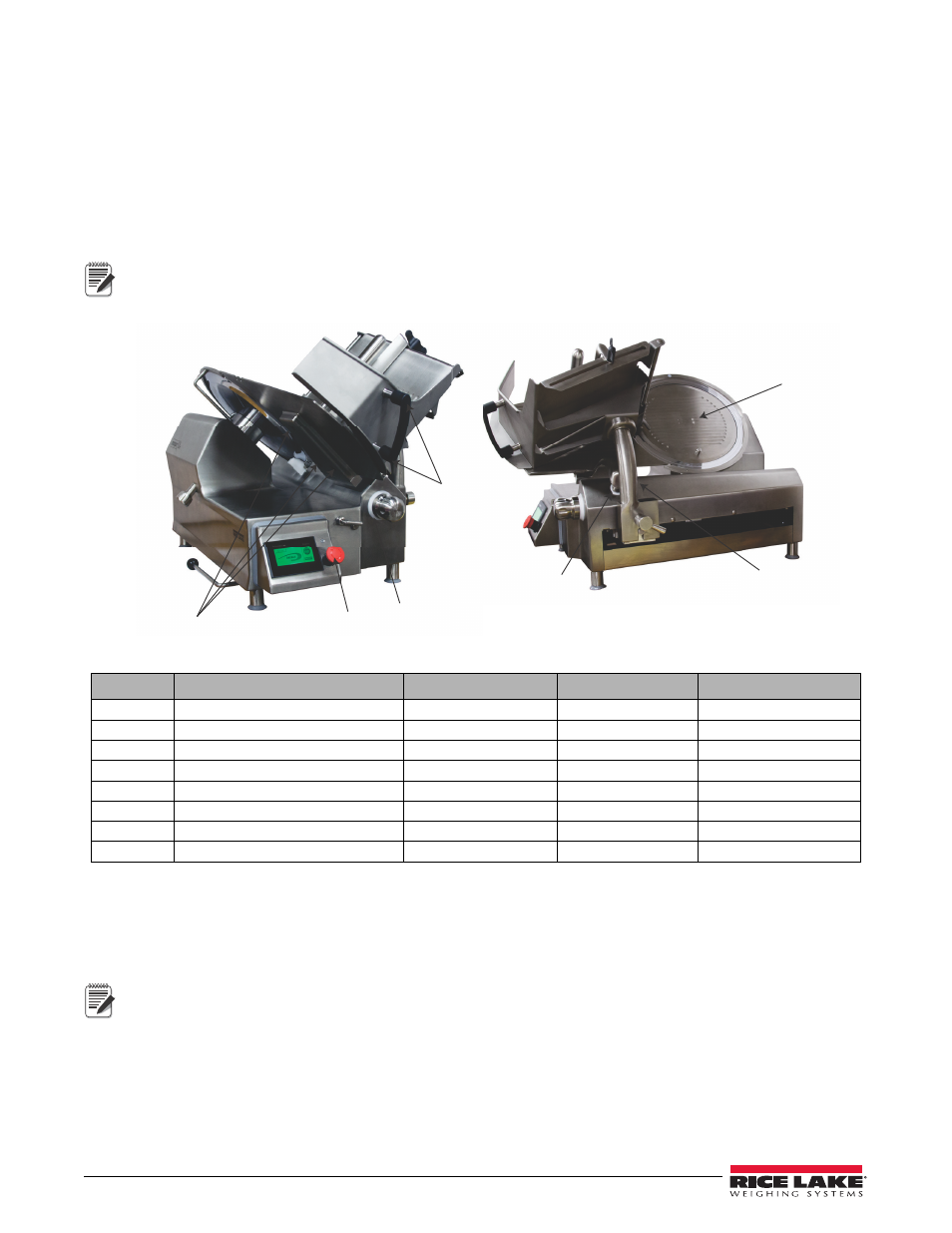

Gasket Inspection

Figure 5-10.

Gasket Inspection

The recommended interval between inspections shall not exceed 6 months for components that are detached for

cleaning and sanitizing, and 12 months for all others.

Inspections must be made by Rice Lake Weighing Systems or an authorized service agent.

The slicer must be removed from service until repaired by DADAUX GASTROTECH, RICE LAKE services or an

authorized service agent if any gasket or seal is found to be damaged, or missing.

Label

Description

Material

Quantity

Location

5

Gauge Plate Caps

PEhd

3

Food zone

7

Screw caps

Silicone

2

Splash zone

11

Thickness gasket

PTFE

1

Splash zone

20

Indexing control gasket

PTFE

1

Splash zone

92

Handle cap

PA

1

Splash zone

134

Sealing gasket

NBR

1

Splash zone

E8

Silicone cap

Silicone

1

Splash zone

E9

Silicone cap

Silicone

1

Splash zone

Table 5-3. Gasket Inspection

Note

Back

Front

5

7

E8

11

134

20

92

Note