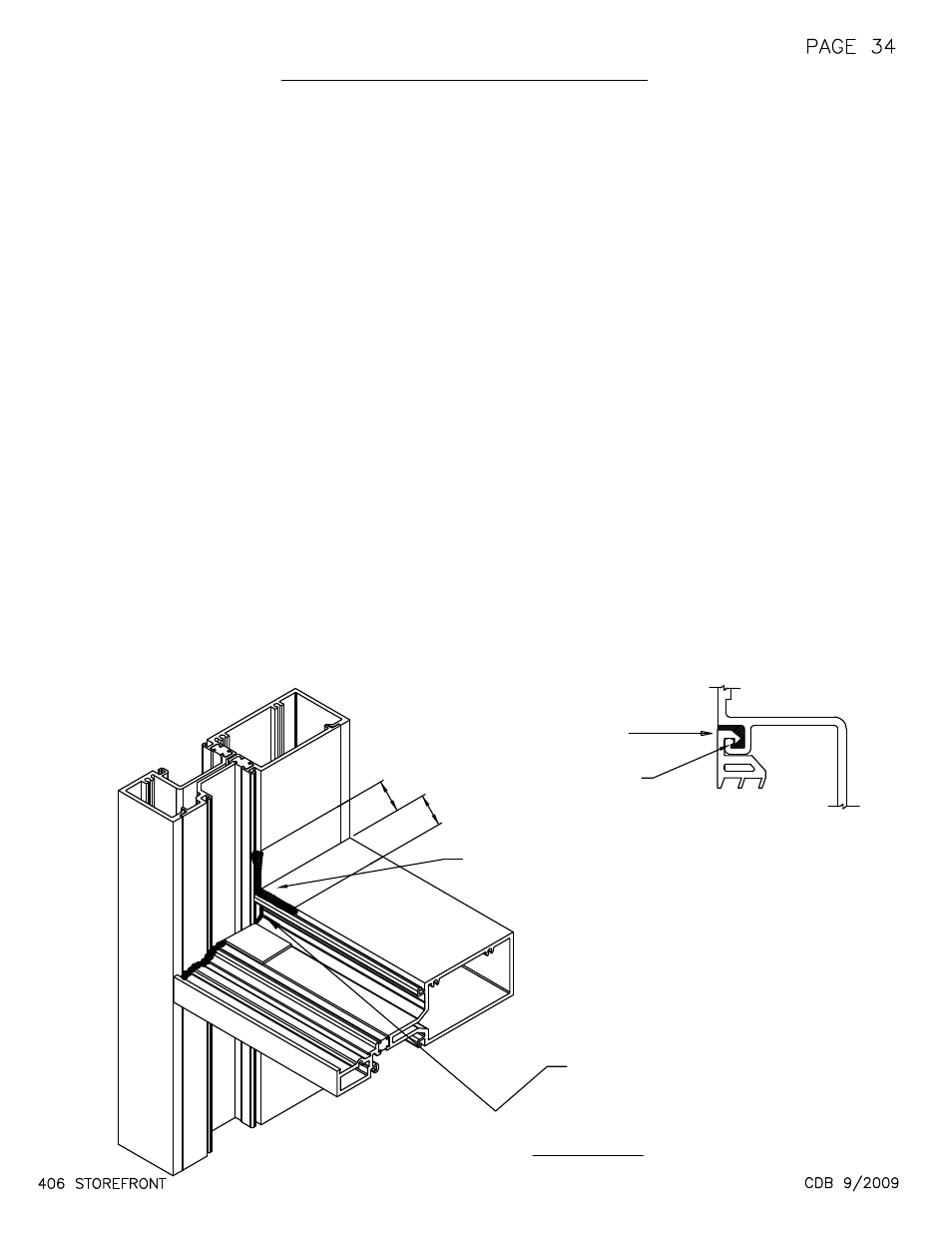

Glass installation, B - glass installation, Fig. # 40 – EFCO 406 (T) Series User Manual

Page 36: Step 1) gasket installation for outside glaze

E) Clean the glazing gaskets with denatured alcohol at the intersection area.

Apply a small amount of sealant at the intersect area to marry the vertical

and horizontal glazing gaskets. Tool all sealant to present a neat,

FORM, CREATING GAPS AT THE GASKET INTERSECTIONS.

DO NOT STRETCH THE GASKET OR IT WILL RETURN TO ITS ORIGINAL

These steps are included in the test lab procedure and are requirements

D) Start at the ends and work toward the center, firmly pushing the

to achieve the test report results for air and water infiltration.

NOTE:

#9359/#9358

gasket in place.

clean appearance.

Fig. # 40

TYPICAL ALL 4 CORNERS OF DLO.

1" FROM INTERSECTION

SEALANT IN INTERIOR GASKET RACE

GASKET RACE

Sealant

#8401

1"

1"

W164

B - GLASS INSTALLATION

B) Cut the interior and exterior push-in gasket to an approximate length of

1" away from the intersection of the vertical and horizontal members.

at the verticals. At all 4 corners of the D.L.O., apply sealant in the gasket race

A) Apply sealant to the ends of all horizontals to seal the intersections

C) Install the interior glazing gasket. NOTE: The vertical gaskets run through.

SECTION V GLAZING

STEP 1) GASKET INSTALLATION FOR OUTSIDE GLAZE.

D.L.O. x 1.02 (DLO PLUS 2%).

See detail # 40 below.

SEAL UNDER THE GASKET TRACK

OF THE HORIZ. & MARRY SEALANT

INTO VERTICAL GASKET TRACK &

HWDI @ INT. HORIZ. ONLY.