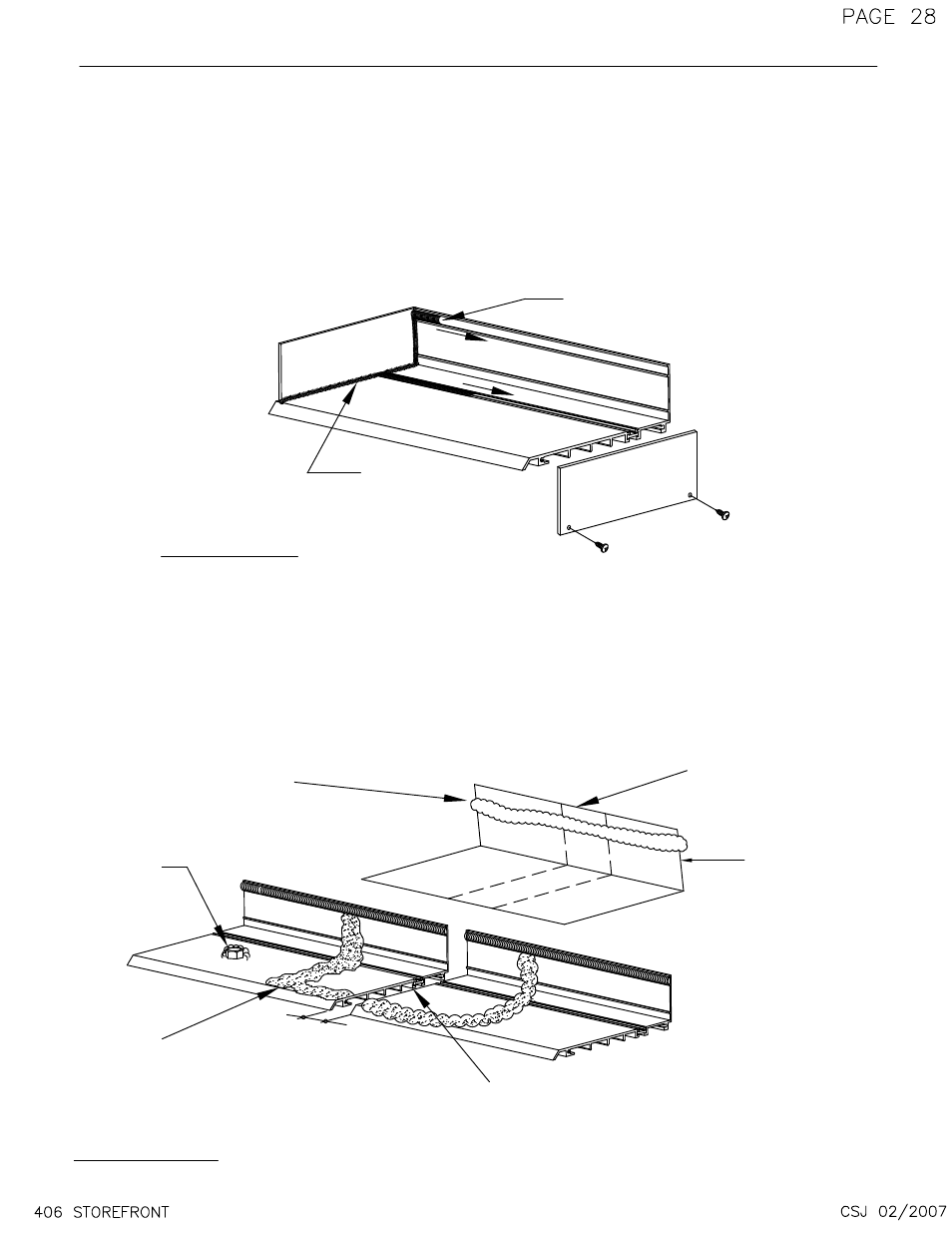

Fig. #31, Fig. #30 – EFCO 406 (T) Series User Manual

Page 30

ALLOW 6" MINIMUM SPACING FROM THE VERTICALS. FOR MITERED

LOCATE THE SPLICE JOINT DIRECTLY AT A VERTICAL INTERMEDIATE.

K979 FOR S406 HIGH PERFORMANCE FLASHING. IT IS NOT ADVISED TO

SPLICE THE FLASHING EVERY 20'-0" AS SHOWN IN FIG. #31 BELOW. USE

WOULD BE, IF THE JAMB CONDITION IS LESS THAN THE SILL FLASHING

COULD NOT BE SEALED TO THE CONDITION COMPLETELY. AN EXAMPLE

CAPS. END CAPS WOULD BE INCORPORATED IF THE SILL FLASHING

SILL FLASHING CUT LENGTH = ROUGH OPENING MINUS 1/2" WITH END

SECTION IV ASSEMBLY & INSTALLATION

C - SILL FLASHING INSTALLATION

Bond breaker tape

After the splice is in place, apply

back of splice.

1" wide centered on

formed sleeve

.050 aluminum

interior gap vertically.

the cosmetic seal to the

for # 1G83

& # 1G86

K980

FIG. #31

CORNERS, SEE PAGE 29.

DEPTH OR IF THERE IS A VOID IN THE CONDITION.

FIG. #30

when in place to ensure the

Reapply sealant across the splice

bead of sealant is continuous.

of sealant around the perimeter

Set sill flashing splice in a bed

of the splice.

over all screw heads.

6" from verticals and

24" O.C. and seal

Anchor sill flashing

STEP 5)

STEP 4)

in the sill flashing.

silicone to fill the joint

Use backer rod and

3/8"

Sealant

K979

Sealant

(CONT.)