EFCO S5600 Structural Glazed User Manual

Page 21

EFCO CORPORATION 7/2012 PART NO. Y306

Page 21 of 28

Series 5600 Silicone Structural Glazed Installation Instructions

Section VI: Glazing Preparation

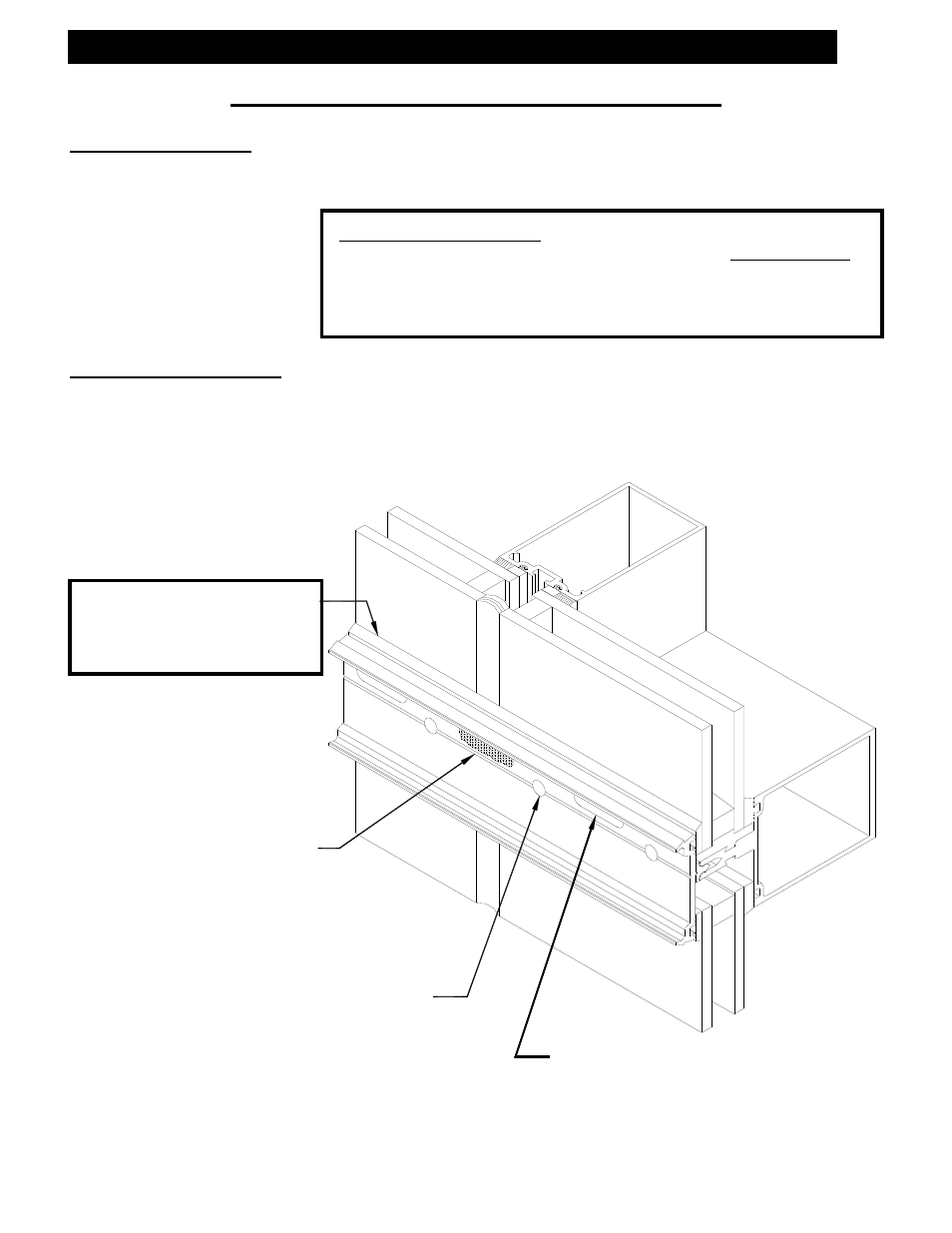

Position Glass Infill

A.)

Set glass in framing opening, tight against interior gaskets, and position squarely on

setting blocks.

Attach Pressure Plates

A.)

Install all pressure plate screws at 6” O.C. When possible, work from the center

outward. Torque all screws to 80 inch pounds after both sides of opening have

been secured. Fasteners must not be any more than 3” from each end and 6” O.C.

Note: Preapply

exterior

gasket in pressure

plates. Cut gaskets

¼” long at each end.

Just prior to installing the

pressure plate, apply

sealant to the face of all

joint plugs.

(Intermediates and Jambs.)

Insert a screw in the first hole

on each side of vertical that is

no closer than 3” from the

center of the vertical mullion.

3/16” X 1” weep slots

2 per lite- 4” off the

edge of the mullion.

Customer / Installer Note: EFCO setting blocks are typically 4" in

length with different depths. If the glazing infill is "NOT BY EFCO"

and glazing sizes are larger than 40 square feet, then the glazing

details must be reviewed by the glazing manufacturer for proper

setting block size.