EFCO S5600 Structural Glazed User Manual

Page 11

EFCO CORPORATION 7/2012 PART NO. Y306

Page 11 of 28

Series 5600 Silicone Structural Glazed Installation Instructions

PRESSURE

PLATE SCREW

P

R

E

S

S

U

R

E

PL

AT

E LEN

G

TH

M

U

LLI

ON LENGT

H

COVER LENGTH

2"

2"

PR

ESSURE

PLATE

LENGT

H

MULLION L

E

NGTH

COVER LEN

G

TH

1/2"

1 "

1

/2

"

1/

2

"

4"

3" M

IN

.

2"

1" MIN.

4 1

/2"

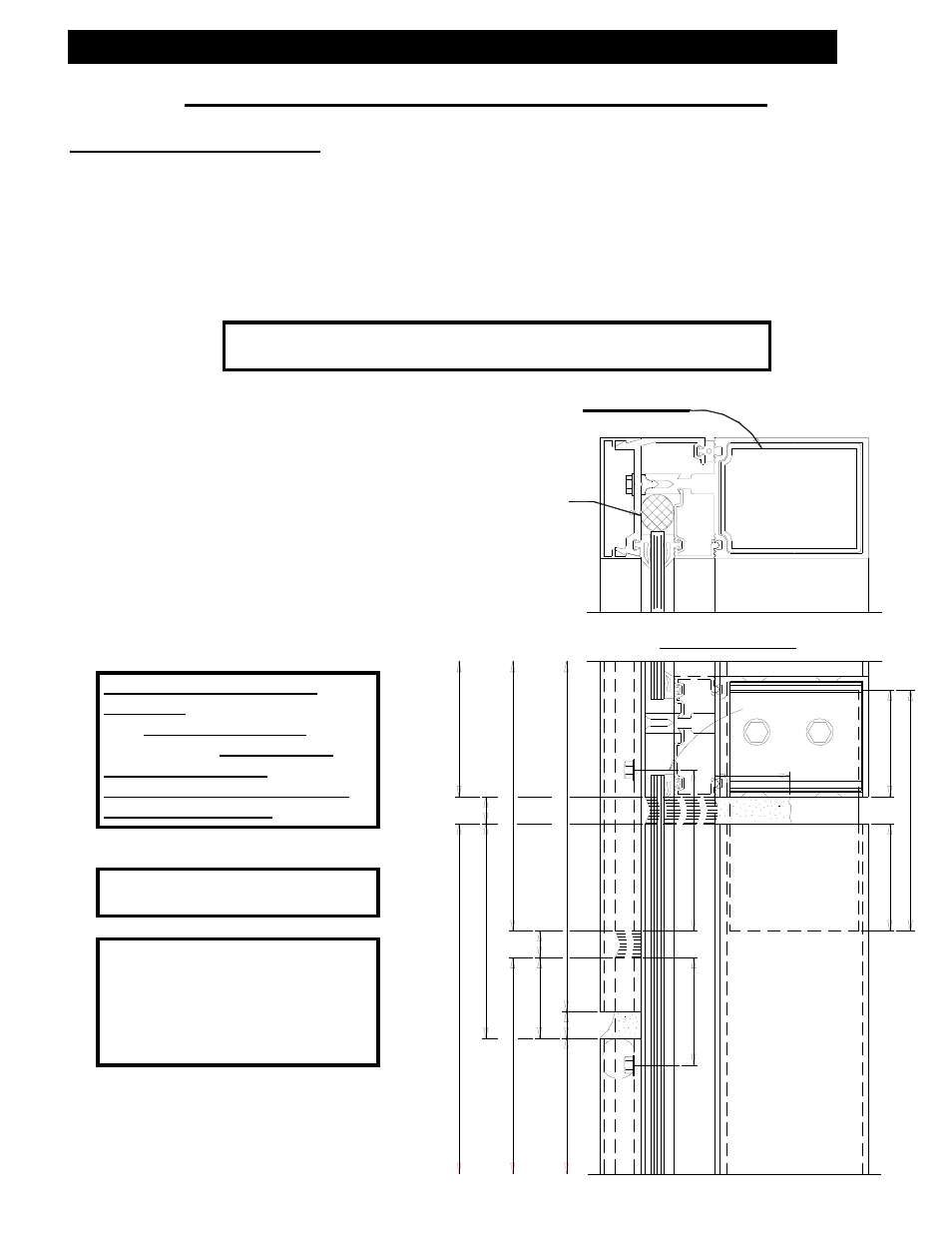

Section V: Vertical Jamb Splice Joints

Vertical Jamb Splice Joints

A.)

Splice joints should occur at spandrel areas. Mullion splice joints for this system are

not designed to compensate for varying floor levels. (Reference “APPROVED” shop

drawings for allowable adjustment, i.e., anchors.)

B.)

Splice joint width should be based on sealant movement capabilities and the

following formula.

C.)

Where head clearance is

insufficient to allow top mullions

to be lifted over sleeve. A

retractable sleeve will be used.

The sleeve is taped into top

mullion and dropped to stop

screw in mullion below.

D.)

Do not match drill anchors until a

check of expansion joints and

wall installation is made.

Note: All anchors must be fixed

before glazing begins.

Note: When mull splice is shop

installed into lower

mullion, shear block

screws will be used in

standard locations, as

shown dotted.

Mullion splice

sleeve with

bond breaker

tape.

Field install

backer rod at

pressure plate

joint to back

up sealant.

Slip-in Horizontal

Linear expansion for aluminum, in inches =

[Length] X [F degrees difference in temperature] X [.0000129]

Note: SSG Vertical Splice

Locations EFCO recommends

that Vertical Splice Line should

be below the Intermediate

Horizontal Member, this will

Minimize Shear Stress at the

Structural Seal Line.