EFCO S5500 Advanced User Manual

Page 24

EFCO CORPORATION 6/2012 PART NO. Y557

24

Series 5500 Advanced & Alternate Installation Instructions

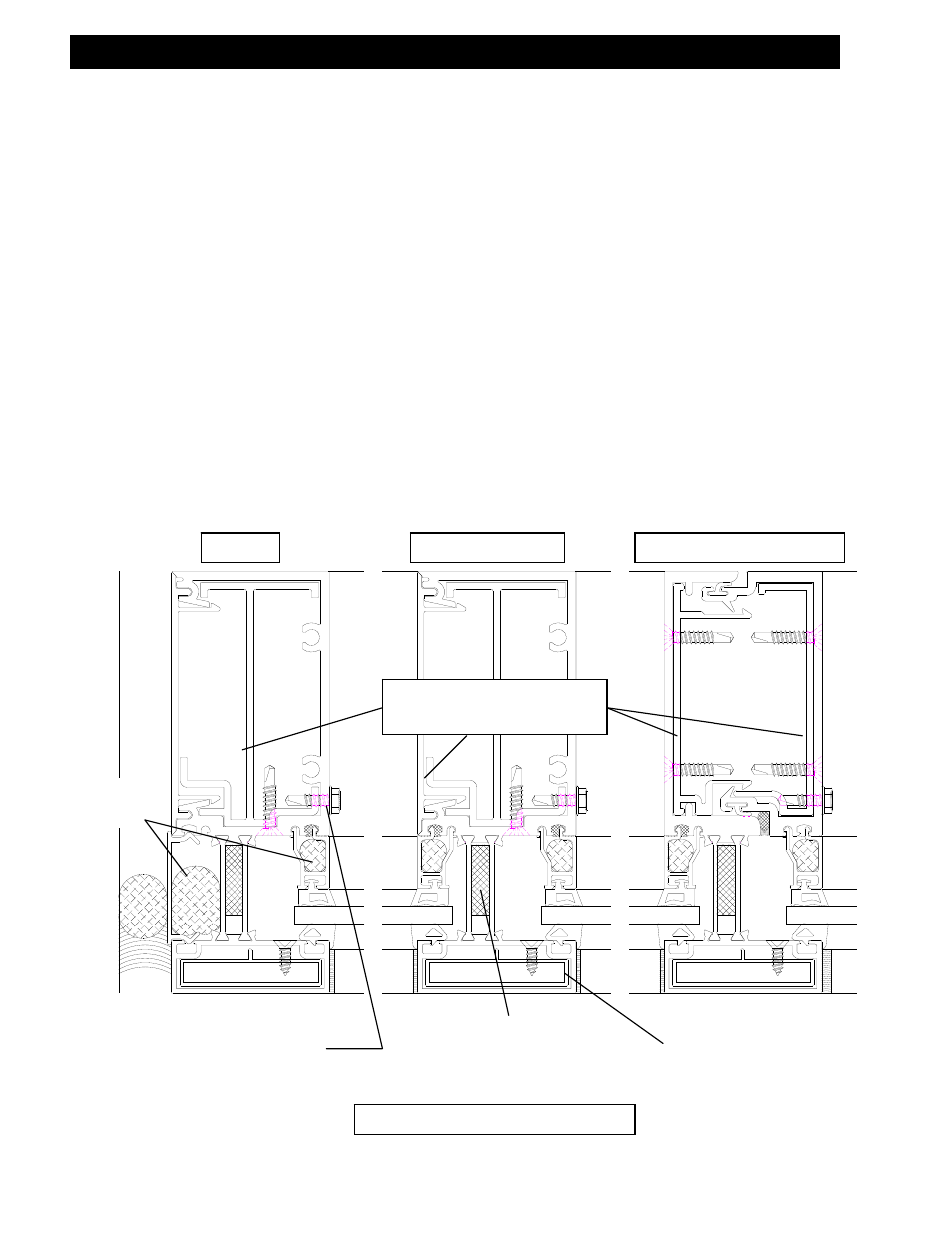

Section V: Vertical Splice Joints

STEP #1 LOCATE SPLICE JOINTS

A. Splice joints should occur at spandrel areas (if possible). Refer to the approved shop

drawings for actual locations.

B. Depending on job requirements, the mullion splice may be shop or field assembled in

the top of the lower mullion. The cover splice is attached to the bottom of the upper

mullion. Where head clearance is insufficient to allow the top mullion to be lifted over

the splice sleeves, retractable splices should be used. The splices are to be taped into

the bottom of the top mullion and dropped down to the stop screw in the mullion

below.

C. GENERAL NOTE: The following pages depict a splice joint of 1/2”. This will allow plus

or minus 1/4” of movement for each splice location. Thermal expansion and live

deflection requirements should be considered when determining the location and

quantities of splice joints. If the total amount of movement cannot be accommodated

locating splices at every other floor or alternatively at each floor, expansion

horizontals or some alternative method should be used. Contact EFCO for further

evaluation.

D. Refer to this section for pressure cover splice locations, mullion splice locations, and

sealing instructions.

E. Once a final check of expansion joint placement and mullion position is made, the final

match drilling of mullion through anchor holes may be completed.

SPLICE SLEEVE

STOP SCREWS

BACKER

ROD

PLAN VIEW – MULLION SPLICE

Mullion splice sleeves

with bond breaker tape.

JAMB

INTERMEDIATE

EXPANSION MULLION

Cover splice sleeves

with bond breaker

tape.

¼” X 1” X 5” FOAM

CAULK JOINT BACKER