Connecting to the breakout board, Connecting to the shop air – Dynojet Spring Applied Air Release (SAAR) Brake Assembly User Manual

Page 22

Spring Applied Air Release (SAAR) Brake Assembly Installation

S P R I N G A P P L I E D A I R R E L E A S E ( S A A R ) B R A K E A S S E M B L Y I N S T A L L A T I O N

Installing the SAAR Brake Assembly

18

C

ONNECTING

TO

THE

B

REAKOUT

B

OARD

1

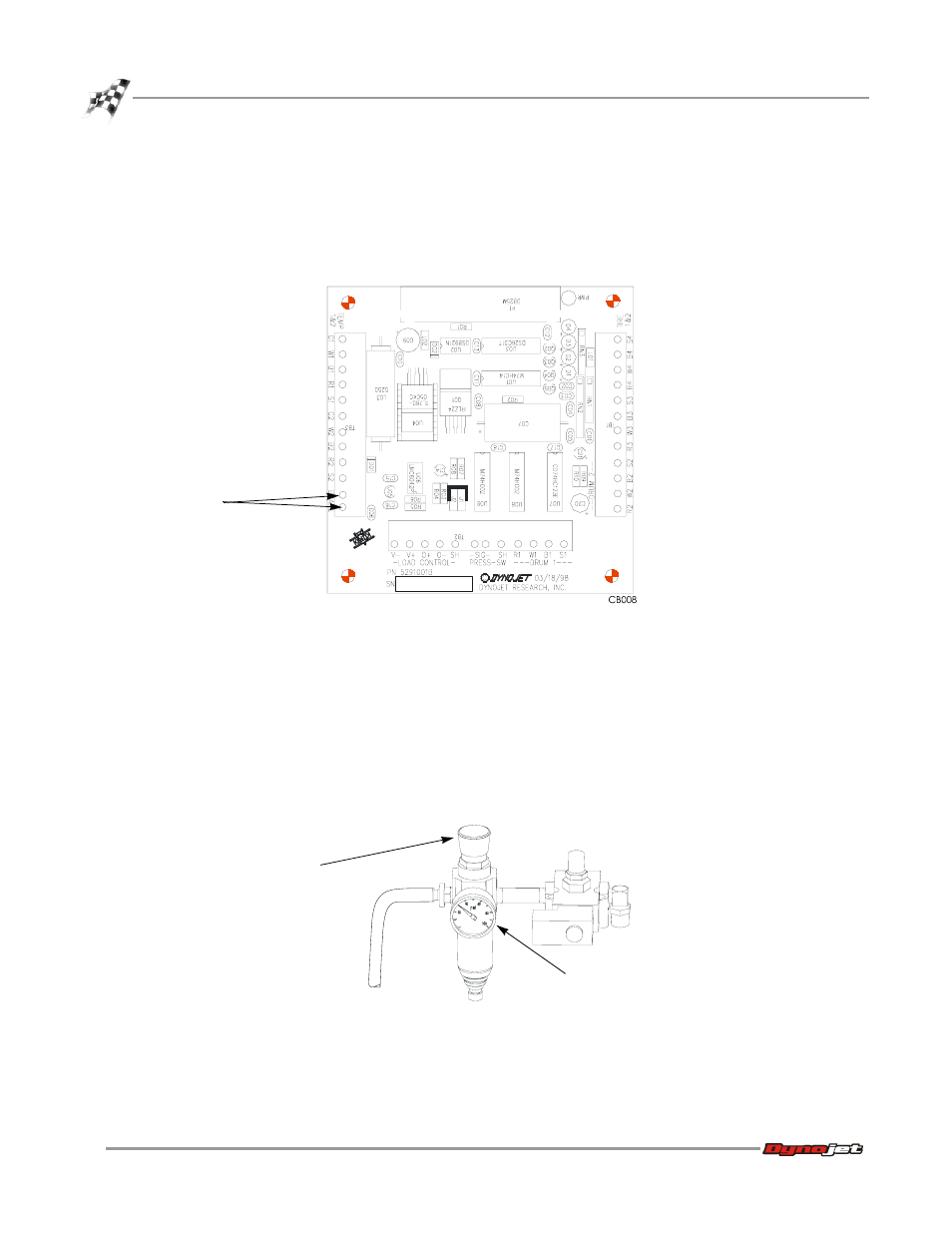

Connect the two black wires from the solenoid to the two terminals on the

breakout board labelled BRAKE (one to each terminal).

2

If you have a 4 wheel drive dyno model 224-248 or 224-224, refer to additional

instructions for “Four Wheel Drive Dynos” on page 20.

Figure 19: Connect the Brake Solenoid Wires to the Breakout Board

C

ONNECTING

TO

THE

S

HOP

A

IR

1

Connect shop air to the fitting on the brake air can pressure regulator. See

Figure 22 on page 21 if you are installing the brake on a four-wheel drive dyno.

2

Adjust the air pressure by pulling up on the regulator knob and turning

counterclockwise to decrease the pressure to 30 psi (clockwise to increase).

Note: The Spring Applied Brake should be operated at 100 psi, but you will start

with the pressure lower while connecting the air can to aid in lining up the parts.

Figure 20: Adjust the Air Pressure

connect the two black

wires from the brake

solenoid to the

breakout board

BR

A

K

E

0

AB092

pull up on regulator

knob and adjust

pressure to 30 psi

pressure gauge

should read 30 psi