Detex ML-1549W User Manual

Detex Safety

During installation, care must be taken to assure full electro -magnet and armature contact .

The ElectroMagnetic Lock and armature should be handled carefully . Any damage to the surface such as paint , burrs and dirt

will hinder full holding power .

Although all ElectroMagnetic Locks are provided with the best possible plating for corrosion resistance , the continued impact

of the armature against the ElectroMagnetic Lock may cause eventual wear of the plating .

If wear causes rust to occur, clean the surface using a fine abrasive pad . Do not use

coarse material to clean surfaces .

After cleaning, do not touch the ElectroMagnetic Lock face or armature with your hands .

A rust inhibitor such as M1 manufactured by Starret , or LPS3 manufactured by LPS

Laboratories (available at most hardware stores ) may be applied .

Mount the ElectroMagnetic Lock to a fence post or similar structure . The armature is mounted to the gate . The fabrication of

additional mounting plates and angle brackets may be required by the installer . Due to various gate and fence designs , there

is not a standard or recommended method of installation .

ElectroMagnetic Locks are fail-safe (locked when energized ) devices and require power to remain locked . A power supply

with battery backup is required when power outages may interfere with desired security .

ML-1549W / ML-1549WF ELECTROMAGNETIC LOCK

INSTALLATION INSTRUCTIONS

1. Inspect the gate and post to determine if any modifications are required . Install mounting hardware as required .

2. Mark the mounting surfaces per the template . Be sure the centerline of the armature template matches the centerline of

the ElectroMagnetic Lock template . Drill and tap holes as indicated .

2A. Add spring pins to armature . See page 3

3. Mount the armature to the gate . Determine the proper hardware (provided ) see Figure 1. DO NOT SUBSTITUTE

ARMATURE MOUNTING HARDWARE AND DO NOT WELD THE ARMATURE DIRECTLY TO THE MOUNTING

SURFACE.

When properly mounted , the armature will pivot slightly around the mounting screw .

INSTALLATION:

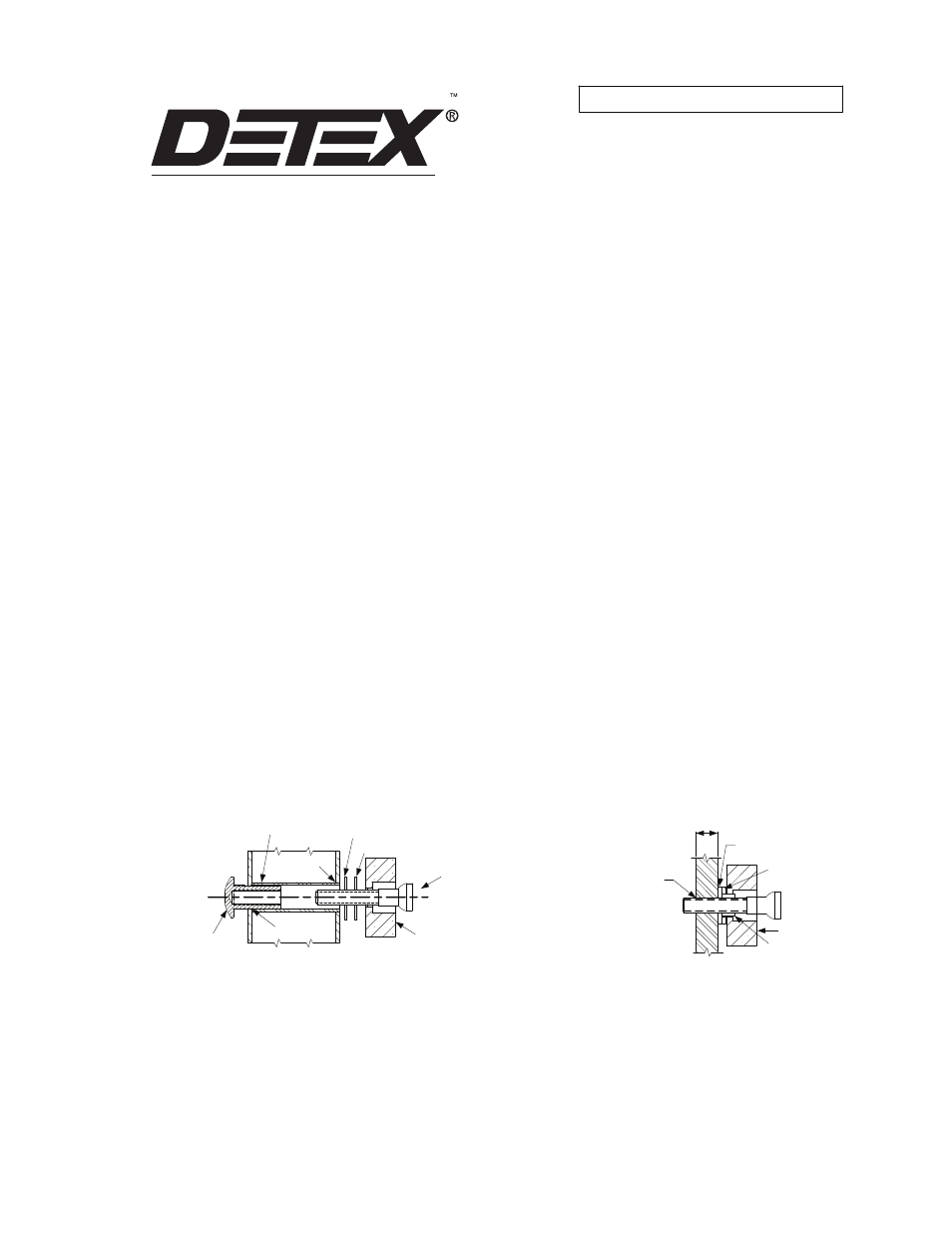

FIGURE 1

From Sexnut side of door, drill exactly 1/2” hole thru one metal thickness only.

From armature side of door, drill 5/8” hole to insert reinforcement tube.

Press in sexnut and reinforcement tube all the way and mount armature to

door using hardware provided.

3/8“ MIN METAL

MOUNTING SURFACE

ARMATURE

SPACER

RUBBER

WASHER

WASHER

Add as required

5/16-18 x 1-½

REINFORCEMENT

TUBE

1-3/4“ HOLLOW

METAL DOOR

5/8“ DRILL

STEEL WASHER

RUBBER WASHER

ARMATURE

1/2” DRILL

SEXNUT

3/8"

5/16-18 x 2

Drill and tape for 5/16 machine screw.

Mount armature to door with hardware provided

.

Page 1

103163

Detex Corporation

302 Detex Drive

New Braunfels , Texas 78130

www.detex.com Tel: (800) 729-3839

P/N 103163 September 18, 2008

Life Safety, Security and Security Assurance

Where T

rust is Built