Electrical specifications, Ml-1500 series connections – Detex ML-1548 User Manual

Page 2

ELECTRICAL INSTALLATION

IMPORTANT NOTES

1. Use jacketed cable for all wire runs. Refer to the AWG wire

gauge chart for proper lock power wire size (18 AWG

gauge minimum).

2. All wires

must be colored coded.

3. Use properly fused power source only. See Electrical

Specifications.

4. Make all ElectroMagnetic Lock terminal connections according to

Figure 3

INDOOR USE ONLY

Do not run power wires and signal wires in the same

cable or conduit.

AWG WIRE CHART

To determine the correct wire gauge to use on “one circuit” the following information is required

:

1. The quantity, voltage, and current draw of all lock(s) to be used.

2. The distance in feet from the power supply to the furthest lock.

Add together the current draw (amps) of all locks on the same circuit. Cross reference the total amps with the distance between the

power source and the furthest lock to determine the wire gauge required. All wiring must be installed in accordance with all state and

local codes.

DISTANCE IN FEET FROM POWER SOURCE TO FARTHEST LOCKING DEVICE

Minimum

Wire

Gauge for

24 Volts

DC

AMPS

0.25

0.50

0.75

1.00

1.50

2.00

2.50

25

50

75

100

150

200

250

300

400

500

1000

18

18

18

18

18

18

18

18

16

16

16

18

18

18

18

18

16

16

14

14

12

18

18

18

18

16

14

14

12

12

18

18

16

16

14

14

12

12

18

18

16

14

14

12

18

16

14

14

12

18

16

14

12

TROUBLE SHOOTING .

ELECTRICAL SPECIFICATIONS

Voltage kickback protection standard

*NOTE: For a proper coil resistance reading, turn off the DC voltage. Use an ohmmeter and measure

the resistance between the pins of the plug connector positions E1-E2 and E3-E4

Page 2

103162

Page 3

103162

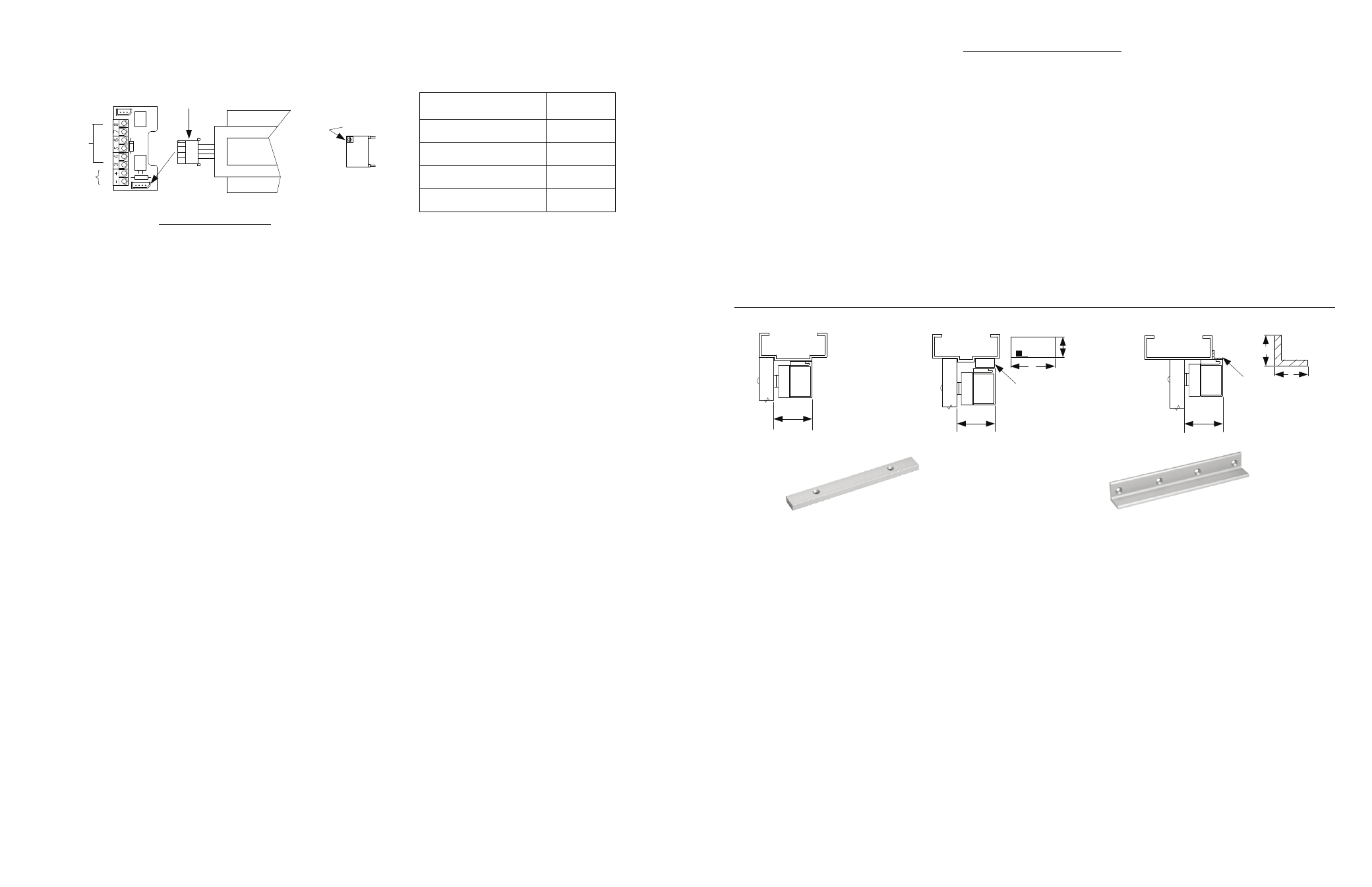

SERIES

INPUT VOLTAGE (VDC)

POWER CONSUMPTION (mA)

COIL RESISTANCE (OHMS)

HOLDING FORCE (LBS)

ML-1500

24

350

1650

35 (PER COIL)

*

RT

TIME ADJ.

AVAILABLE OPTIONS

RT

TIME DELAY (1-30 sec)

LOCK PWR

-+

ELECTROMAGNET

PLUG CONNECTION

FIG. 3

LOCK

E4

E3

E2

E1

J1

No

t U

se

d

ML-1500 Series Connections

Figure 1

Regular

2-5/16"

59mm

Figure 1B

Filler Plate

Filler

Plate

2-5/16"

59mm

B

A

Figure 1C

Angle Bracket

2-5/16"

59mm

Angle

Bracket

B

A

P/N 103916

P/N 103917

FILLER PLATES: For extension of the stop to provide a

proper mounting surface on the underside of the header.

See Figure 1B.

FOR ML-1500 SERIES MODELS

PART #

103916

SIZE

B

A

5/8” x 1-1/4" x 11" (16 x 32 x 279mm)

ANGLE BRACKETS: Used as extension on shallow door

frames to provide adequate mounting surface.

See Figure 1C.

FOR ML-1500 SERIES MODELS

PART #

103917

SIZE

B

A

2” x 1-1/2" x 11" LG (51 x 38 x 279mm)

Available kits:

Armature hardware kit P /N 103918-1

ElectroMagnetic lock hardware kit P /N 103918-2

Problem

ElectroMagnetic lock releases

slowly. (residual magnetism)

Cause

Control switdch wired on DC side of power source

Solution

Control switch must be wired on DC side of power supply.

Poor holding force.

Armature installed rigidly.

Armature must pivot loosely from its center mounting point to

permit full armature contact.

Low voltage

Check for proper voltage at the ElectroMagnetic lock input. If

low, determine if the correct wire guage is being used to

prevent excessive voltage drop.

No holding force

No power

Check power supply load capacity. It must meed or exceed

the combined current rating of all locks on the circuit.

Door does not lock.

Input polarity reversed.

ElectroMagnetic locks require DC input voltage.

Check coil continuity with OHM meter. If reading is high

or open, replace the magnet coil. See Fig. 3 and the

Resitance Specifications.

Open circuit in ElectroMagnetic Lock coil .

Coil shorts or incorrect wiring will blow fuses.

Measure the coil for correct resitance. See Fig. 3

and the Resitance Specifications.

Magnet coil short.