Salter Brecknell 650 User Manual

Page 23

23

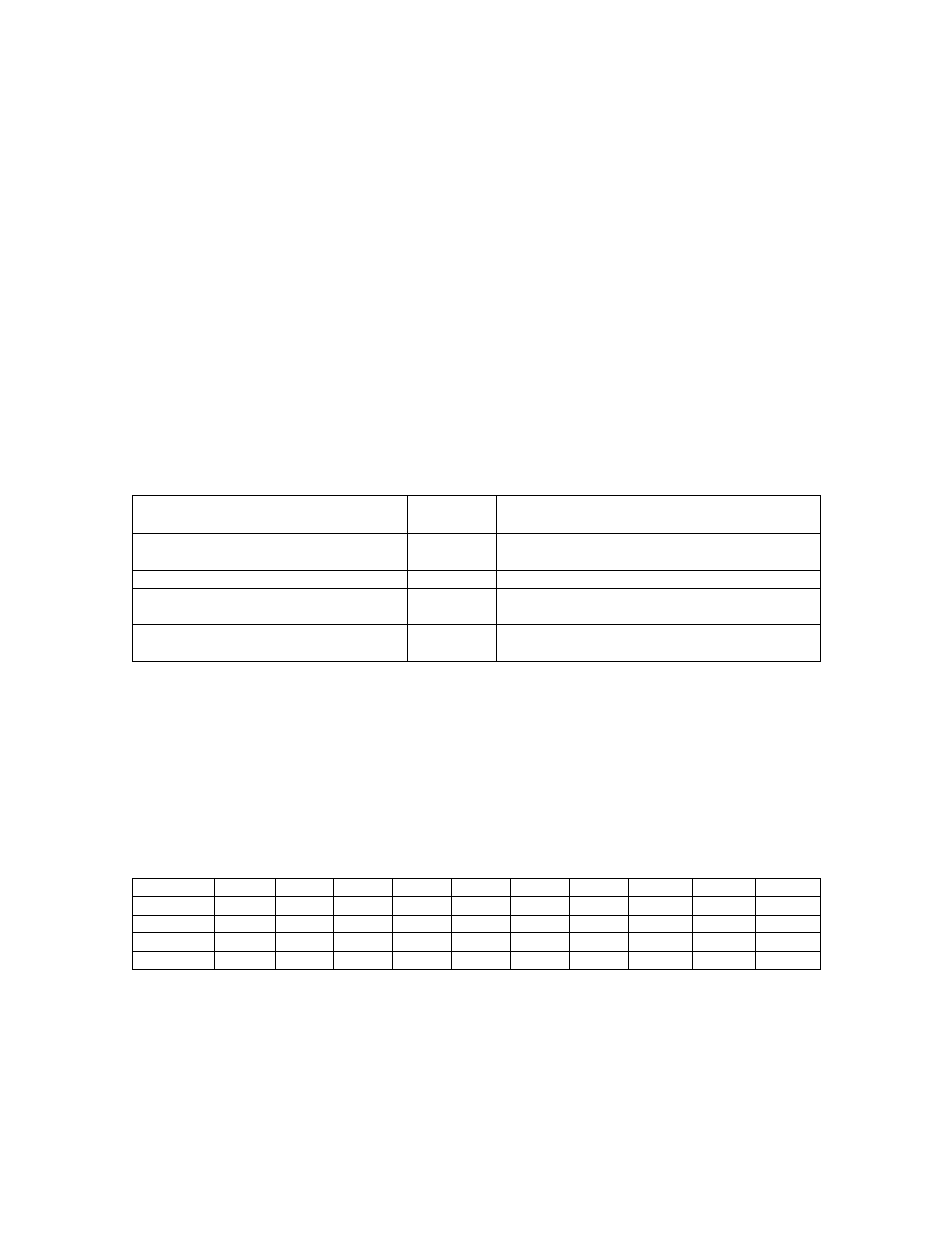

5.3 SUPER SUB MENU

Table 5-2 lists the items which are contained in the Supervisor sub-menu. The

SUPER password is 2222.

To access the Supervisor sub-menu, follow the instructions below.

1. Press the * button and scale prompts “Select a setup menu”.

2. Press the SUPER soft key. The prompts for “Input Password. Enter 2222. The

Supervisor sub-menu items are listed above the soft keys.

3. Press the soft key pertaining to the item you wish to modify. The scale shows the

current status or selection of that item in the form of a highlighted soft key text.

4. Press the soft key corresponding to the desired status then press the ENT key.

You may exit this screen without making changes by pressing the CLR key.

5. Repeat steps 3 and 4 above until the Supervisor setup is complete.

6. Press the CLR key twice to return to normal operating mode.

ITEM

SOFT

KEY

DESCRIPTION

Accuracy Enable Disable

ACCY

Allows you to enable or disable the

controlled accuracy feature

Minimum Sample

MINSPL

Sets the minimum sample size value

Local Scale Filter

LOCFLT

Sets the amount of filtering on the TC2010

platform

Remote Scale Filter

REMFLT

Sets the amount of filtering on a remote

platform

TABLE 5-2: Supervisor Sub-menu Items

5.3.1 ACCURACY

1. Pressing the accuracy soft key will prompt for a password. Enter 1111. You will

then be prompted to enable or disable. If you select enable, the scale prompts for

“ Accuracy Setup” with soft keys showing percentage amounts. The higher the

selected percentage, the greater the sample weigh must be regardless of the

number of pieces. Table 5-3 illustrates the weight required in pounds for each

capacity 650 and percentage setting:

Capacity

NONE

94%

95%

96%

97%

98%

99%

99.6%

99.8%

99.9%

12 lb

0

.012

.016

.024

.036

.048

.060

.072

.096

.120

30 lb

0

.030

.039

.060

.090

.120

.150

.180

.240

.300

60 lb

0

.060

.078

.120

.180

.240

.300

.360

.480

.600

120 lb

0

.120

.156

.240

.360

.480

.600

.720

.960

1.20

TABLE 5-3: Sample weight required for controlled accuracy

2. The percentage accuracy does not guarantee an accurate piece count. It controls

the performance of the scale but cannot overcome variances in part weight. It is

one half of controlled accuracy.

3. If the number of samples used does not meet the minimum weight required, the

scale will prompt for more pieces until the minimum weight is reached.