B&M 35229 TRANSPAK User Manual

Page 7

ing level as required. Test drive vehicle

and recheck for leaks while transmis-

sion is hot.

TROUBLE SHOOTING

Most problems can be traced to

incorrectly installed components. If the

transmission makes unusual noise or

feels as if it is binding up, turn off the

engine immediately. Go back and re-

check the entire installation.

If the problem is shift quality (slip-

ping, hard, early, late) then do the

following:

1. CHECK TRANSMISSION OIL

LEVEL.

2. CHECK AND ADJUST TV CABLE.

3. CHECK OUTSIDE MANUAL LINK-

AGE.

If the above does not remedy the

problem, then perform the following di-

agnostic oil pressure check:

1. CHECK ENGINE TUNE

2. INSTALL A 0-2,080 kPa (0-300

PSI) OIL PRESSURE GAGE. THE LINE

PRESSURE TAP IS LOCATED JUST

ABOVE THE OUTSIDE MANUAL LINK-

AGE ON THE LEFT HAND SIDE OF

THE CASE.

Check oil pressures in the following

manner:

Minimum T.V. Line Pressure

Check: Set the T.V. cable (See Fig.

11) With the brakes applied, take the

line pressure readings at the selector

lever position and engine R.P.M. speci-

fied in the chart.

Maximum T.V. Line Pressure

Check: With the brakes applied, hold

or tie the T.V. cable in it’s fully extended

position then take the line pressure

readings again at the selector lever

positions and engine R.P.M specified

in the chart. IMPORTANT: Only ex-

tend the T.V. cable for this test. DO

NOT open throttle to wide open posi-

tion.

Basic line pressure is controlled by

the pumps output volume and the pres-

sure regulator valve. The T.V. system

which is controlled by the T.V. cable

causes line pressure to increase with

increased throttle opening. Because of

system requirements line pressure is

boosted by the reverse boost valve and

sleeve assembly when the selector is

in the Reverse, D2 or D1 position.

If the oil pressure readings are low,

high or do not change when the T.V.

cable is extended (except in D2 & D1

where pressure should remain con-

stant) then look at the pressure regula-

tor assembly for sticking valves or in-

correct order of assembly.

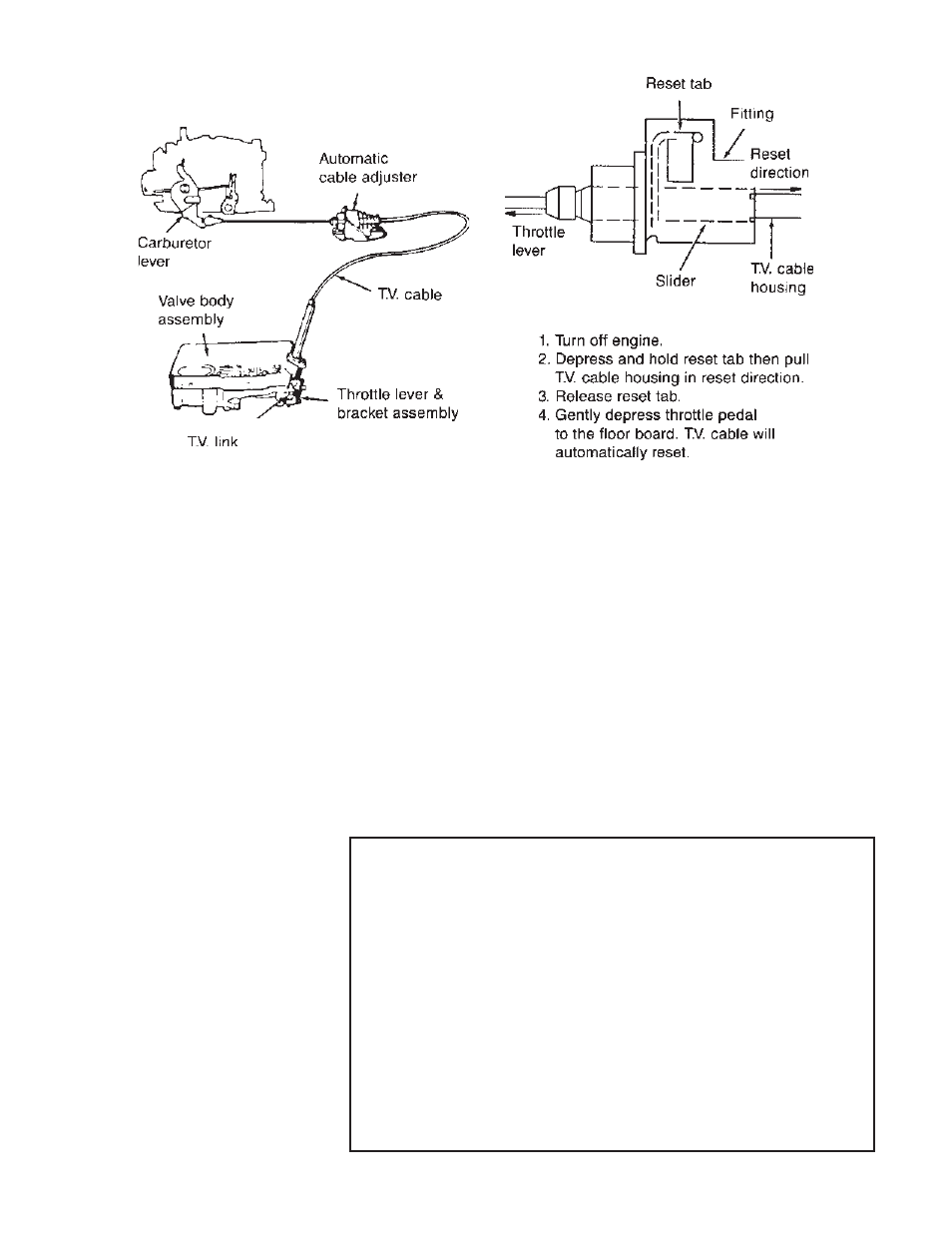

Fig. 11. T.V. Cable Adjustment Procedure.

7

T.V. Cable Resetting Procedure

TOOL LIST

Hydraulic jack

Gasket Scraper

Jack stands or Wheel ramps

3/8" Drill motor

Oil drain pan

Fine cut flat file

3/8" drive ratchet wrench

10mm, 13 mm, Sockets

Wet or Dry sand paper

Grease or petroleum jelly

Small punch or scribe

Torque wrench

Small flat screwdriver

Internal retaining ring pliers

Funnel

PARTS LIST

Pressure Regulator Valve

Pressure Regulator Spring (Blue)

Ring Retaining

Spring Line Bias (Red)

Gasket, Valve body upper

Gasket, Valve body lower

Gasket, Accumulator

Gasket, Oil pan

Oil Filter

Spacer, 3/8" (Red)

Spacer, 3/4" (Blue)

Drill, 3/32" (.094)

Drill, 5/64" (.078)