Component test, Status code example, Fig. 4—service label/fault code instructions – Carrier 58MVP User Manual

Page 8

→

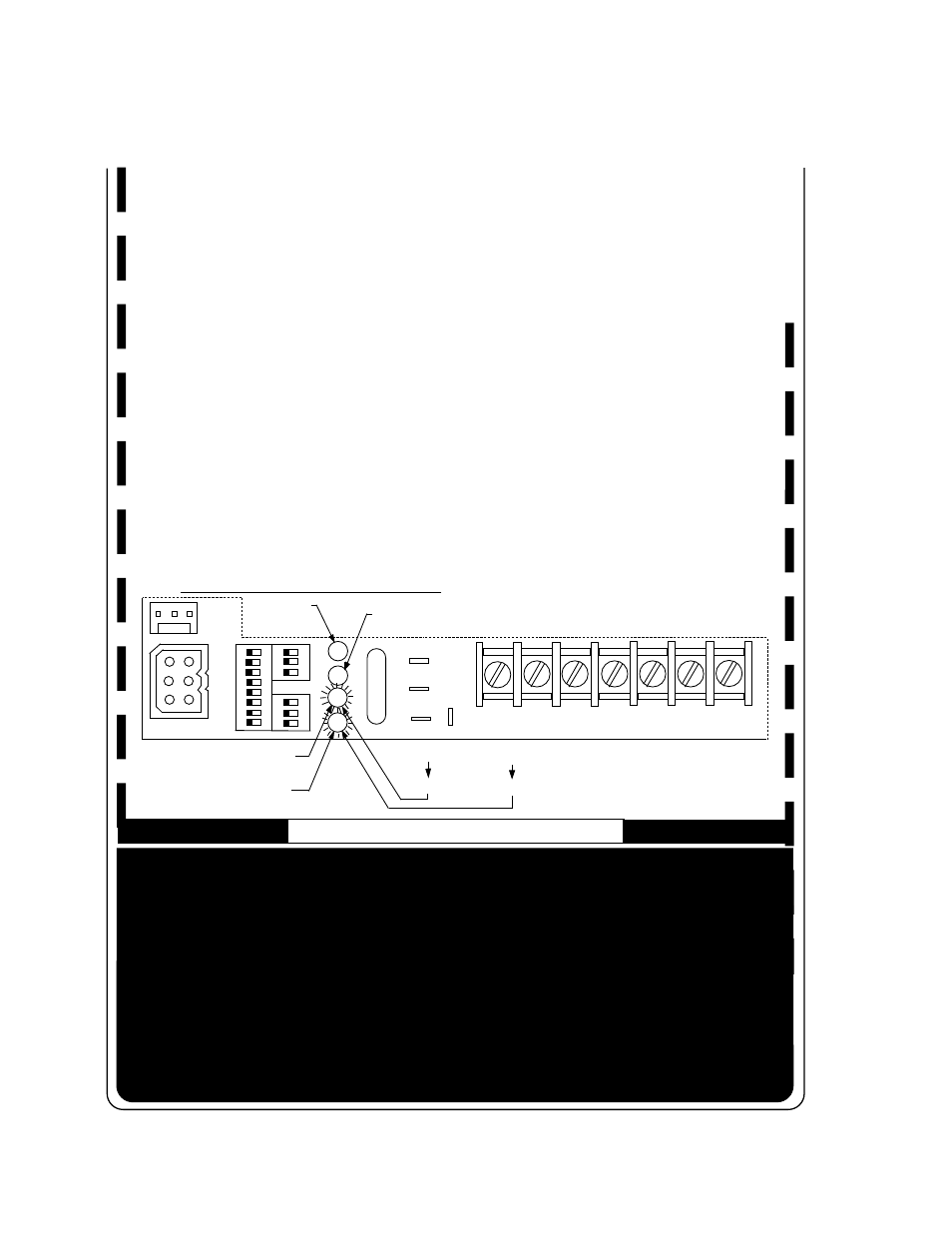

Fig. 4—Service Label/Fault Code Instructions

A99243b

A99243

To initiate the component test sequence, shut "OFF" the room thermostat or disconnect the "R"

thermostat lead. Put setup switch "SW-6" in the "ON" position to start the component test sequence.

Once initiated the main board will turn "ON" the inducer motor-low speed, inducer motor-high speed,

hot surface ignitor, blower motor-low speed, and blower motor-high speed for 15-20 seconds each.

When component test is completed one or more of the following codes will flash. Gas Valve and

Humidifier will not be turned on.

CODE

DESCRIPTION

11 Indicates inducer and blower motor tested OK. Visual check of hot surface ignitor required.

SETUP ERROR - Same as code 22 above.

BLOWER OUTSIDE VALID SPEED RANGE - Indicates blower motor failed test. Check blower, wiring,

and control center.

INDUCER OUTSIDE VALID SPEED RANGE - Indicates inducer motor failed test. Check inducer,

wiring and control center.

22

41

42

To repeat component test turn setup switch "SW-6" "OFF" and then back "ON". After component test is

completed put setup switch "SW-6" in the "OFF" position and reconnect the "R" thermostat lead.

320624-101 REV. J

COMPONENT TEST

STATUS CODE EXAMPLE

=

42 FAULT

HUM

G

R

Y/Y2

W/W1

C

W2

MALFUNCTION

MICROPROCESSOR

RED LED2

EMER HEAT

RED LED1

(2)

(4)

COUNT THE NO.

OF FLASHES

GREEN LED4

LOW HEAT

YELLOW LED3

HIGH HEAT

4

3

2

1

FU

S

E

3

2

1

OF

F

3

2

1

OF

F

1

234

5

6

7

8

OF

F

SE

T

U

P S

W

,(SW

1

-8

)

INDUCER OUTSIDE VALID

SPEED RANGE

OM

24 V

COUNT THE NO.

OF FLASHES

DE

DEHUM

34 IGNITION PROVING FAULT - Control will try three more times before a lockout #14 occurs.

Check for: - Gas valve defective or gas valve turned "OFF".

- Defective Hot Surface Ignitor

- Manual valve shut-off.

- Low inlet gas pressure

- Flame sensor must be ungrounded.

- Green wire MUST be connected to furnace sheet metal.

- Proper flame sense microamps (.5 microamps D.C. minimum, 4.0 - 6.0 nominal in HIGH HEAT)

- Inadequate flame carryover or rough ignition. - Control ground continuity

- Oxide buildup on flame sensor (clean with fine steel wool.)

41 BLOWER OUTSIDE VALID SPEED RANGE - Indicates the blower is not operating at the calculated

RPM. If this fault occurs in conjunction with fault #44 check wiring to motor otherwise refer to

the trouble-shooting guide.

42 INDUCER OUTSIDE VALID SPEED RANGE - Indicates the inducer is not operating at the

calculated RPM, or has not started within 10 seconds after a call for heat. Check wiring to

motor otherwise refer to the trouble-shooting guide.

43 PRESSURE SWITCH CALIBRATION FAULT- Indicates the low and high pressure switch "make"

points during high heat purge are not within the calibration range.

Check for:

- Plugged condensate drain.

- Water in vent piping, possibly sagging pipe.

- Improper pressure switch wiring or pressure switch tubing connections.

- Failed or "Out of Calibration" pressure switches.

44 BLOWER CALIBRATION FAULT - Indicates the calculated blower speed is below 250 or above

1300 RPM. Unit will default to low or high heat mode if possible. If this fault occurs in conjunction

with fault #41 check wiring to motor otherwise refer to the trouble-shooting guide. If this fault

occurs by itself check for undersized ductwork, or excessive static caused by a dirty filter, or

closed registers.

8