Carrier 58MVP User Manual

Page 16

16.

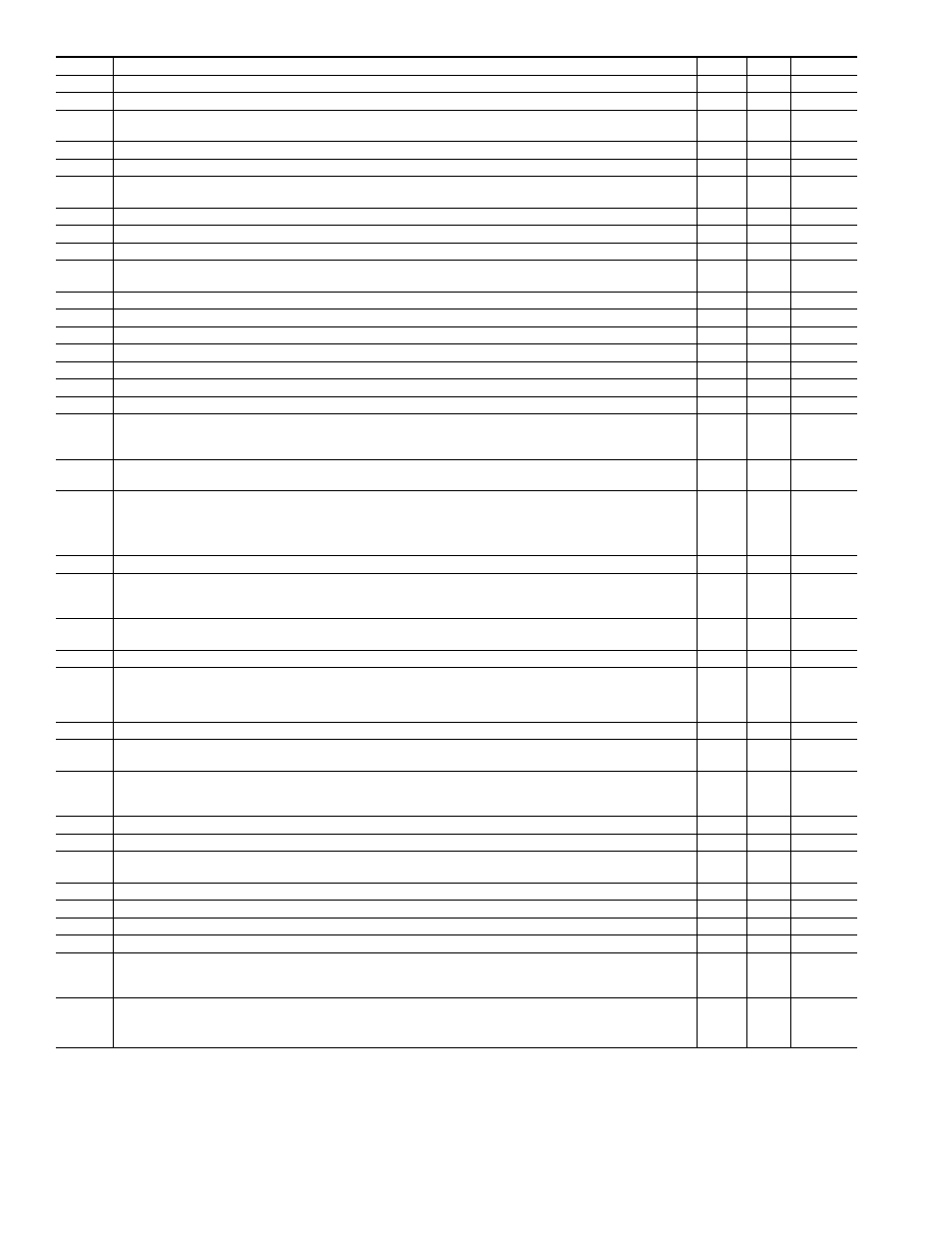

Does the installation have a bypass humidifier?

17

30

—

17.

Is setup switch SW-3 in ON position?

19

18

—

18.

Put setup switch SW-3 in ON position.

—

—

9

19.

Cycle furnace with blower access panel in place and record temperature rise across furnace 6 min-

utes after main burner ignition.

—

—

20

20.

Disconnect jumper wire across R and W/W1 thermostat terminals and wait until blower stops.

—

—

21

21.

Remove blower access panel and put setup switch SW-3 in OFF position.

—

—

22

22.

Cycle furnace with blower access panel in place and record temperature rise across furnace 6 min-

utes after main burner ignition.

—

—

23

23.

Is the temperature rise in Step 22 more than 10°F higher than the temperature rise in Step 19?

24

8

—

24.

Disconnect jumper wire across R and W/W1 thermostat terminals and wait until blower stops.

—

—

25

25.

Remove blower access panel and put setup switch SW-3 in ON position.

—

—

26

26.

Cycle furnace with blower access panel in place and record the temperature rise across return air

duct before and after the bypass.

—

—

27

27.

Is temperature rise from bypass greater than 15°F?

28

29

—

28.

The bypass is oversized. Adjust damper or replace with properly sized bypass.

—

—

9

29.

Disconnect jumper wire across R and W/W1 thermostat terminals and wait until blower stops.

—

—

30

30.

Does the installation have modulating zone dampers?

31

51

—

31.

Is setup switch SW-5 in ON position?

33

32

—

32.

Put setup switch SW-5 in ON position?

—

—

9

33.

Jumper R and W/W1 thermostat terminals on furnace control board.

—

—

34

34.

Does blower recalibrate every minute? Check by monitoring DC voltage across terminals PL3-1

RED (+) and PL3-5 BLUE (-). If DC voltage momentarily goes down to 0 vdc approximately every

60 sec after first blower calibration, then blower is recalibating properly.

35

8

—

35.

Disable modulating zone damper system with all dampers in open position except bypass damper.

If the installation is equipped with a bypass damper, it should be in the closed position.

—

—

36

36.

Put setup switch SW-2 in OFF position. Disconnect jumper wire across R and W/W1 thermostat ter-

minals and reset the power. Reconnect jumper wire across R and W/W1 thermostat terminals and

monitor manifold gas pressure while observing furnace operation for 10 minutes.

NOTE:

Blower access panel must be in place.

—

—

37

37.

Does a Fault Code 33 flash?

39

38

—

38.

The problem is cause by the modulating zone damper system. Install a 2-stage thermostat and let

the zone system modulate gas flow. If you still have a problem, check the zone manufacturer’s in-

stallation and Troubleshooting Guide for corrective action.

—

—

9

39.

While monitoring manifold pressure in Step 36, did it drop to low-fire manifold pressure during low-

fire operation?

49

40

—

40.

Replace gas valve.

—

—

9

41.

Replace blower motor and belly band.

NOTE:

Torque belly band screw to 80 in.lb (6.7 ft. lb).

WARNING: DO NOT OVERTIGHTEN!

—

—

9

42.

Jumper R, W/W1, and W2 thermostat terminals on furnace control board.

—

—

43

43.

Is furnace considerably overfired (10% or more)? Clock input rate. Do not use manifold pressure

method unless using propane.

44

45

—

44.

Ensure gas inlet pressure and burner orifices (natural or propane) are correct. Then adjust gas

valve to proper rate per the Installation, Start-Up, and Operating Instructions. If it cannot be ad-

justed to proper rate, replace gas valve.

—

—

9

45.

Disconnect jumper wire across R, W/W1, and W2 thermostat terminals and wait until blower stops.

—

—

6

46.

Excessive restriction of airflow during locked in high-fire mode caused lockout.

—

—

47

47.

Relieve restriction. Check all dampers, filters, and return-air grilles for blockage. Put setup switch

SW-1 in OFF position.

—

—

42

48.

Fix problem.

—

—

9

49.

Is temperature rise within

±

10°F of midpoint of rise range?

51

41

—

50.

Is temperature rise within

±

10°F of midpoint of rise range?

51

16

—

51.

Turn power off and install a temperature probe in front of limit switch button.

—

—

52

52.

Turn power on and cycle unit. Does limit switch open at a temperature at least 10°F below tempera-

ture setpoint for limit switch. (EXAMPLE: The setpoint is 220°F, but switch opens at a temperature

below 210°F.)

7

53

—

53.

The problem may be related ot poor air distribution. Add turning varies, more supply-air openings,

or more return-air openings. Use Appendix E to evaluate.

—

—

48

16