Fault code 34 – Carrier 58MVP User Manual

Page 26

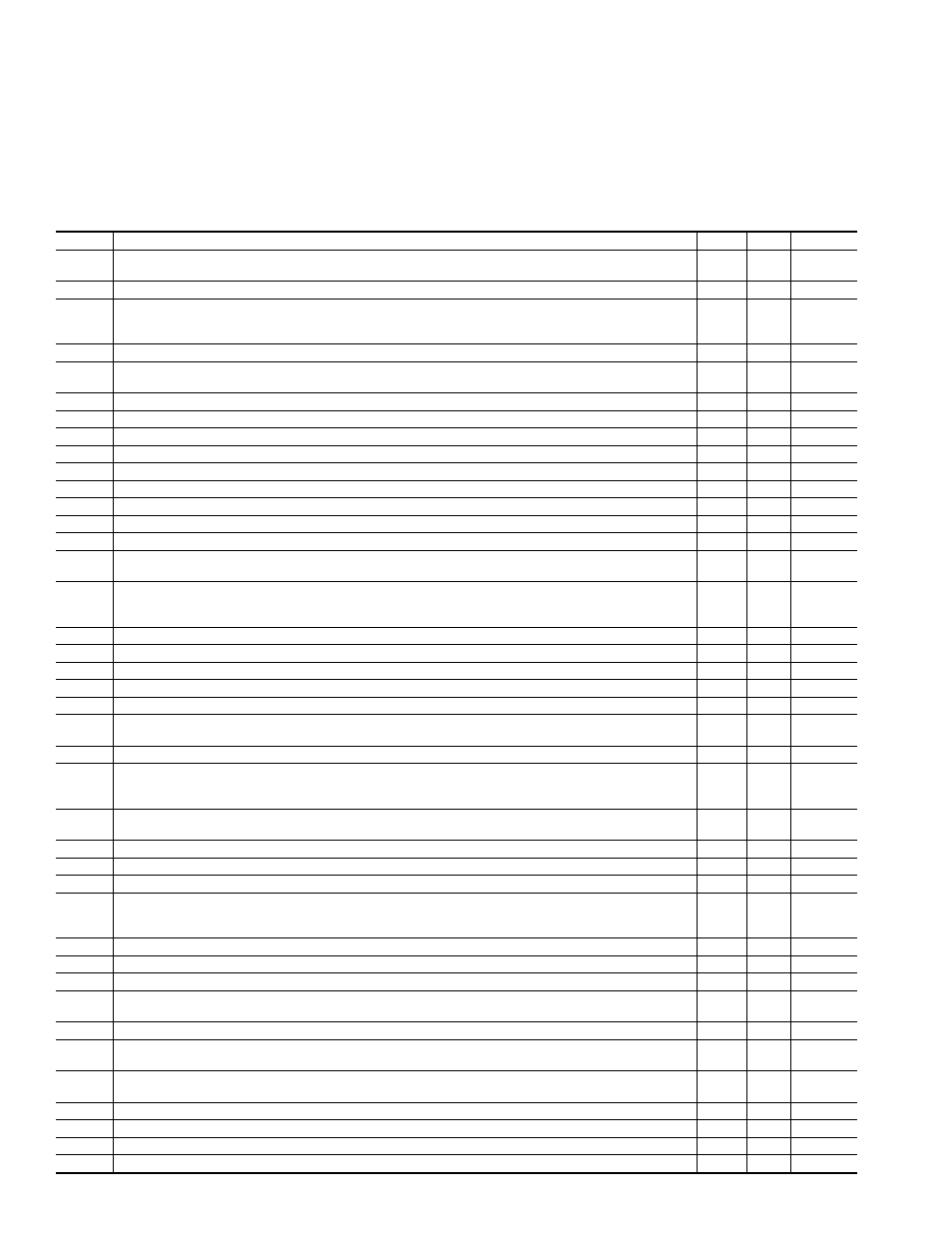

Fault Code 34

IGNITION PROVING FAULT—This fault can indicate 1 of the following:

•

Flame was not sensed during trial for ignition period. The control will repeat ignition sequence 3 more times before going into Fault

14—IGNITION LOCKOUT.

•

The flame signal was lost after trial for ignition period.

•

The flame signal was sensed while gas valve was de-energized. The inducer will run at full speed until fault is cleared.

STEP

ACTION

YES

NO

GO TO

1.

Turn power off, remove blower access panel, and disconnect R thermostat lead from furnace con-

trol board.

—

—

2

2.

Turn power on and depress door switch. Use a piece of tape to hold switch closed.

—

—

3

3.

Make sure thermostat is NOT calling for heat and reconnect R thermostat lead to furnace control

board. Observe unit for 15 minutes. Does inducer motor ever turn on at full speed while furnace

control board flashes Fault Code 34?

4

5

—

4.

Replace furnace control board. Make sure it has a date code 9405 or later.

—

—

12

5.

Disconnect R thermostat lead from furnace control board and jumper R and W/W1 thermostat termi-

nals on furnace control board.

—

—

6

6.

Observe operation of furnace through 1 heating cycle.

—

—

7

7.

Does fault occur again?

13

8

—

8.

Does a different fault occur?

9

10

—

9.

Go to page number indicated in Index for fault code flashed.

—

—

INDEX

10.

Disconnect jumper wire across R and W/W1 thermostat terminals. Does fault occur now?

11

12

—

11.

Replace gas valve.

—

—

12

12.

Go to page number indicated in Index for CLEANUP AND START-UP INSTRUCTIONS.

—

—

INDEX

13.

Turn power off and disconnect jumper wire across R and W/W1 thermostat terminals.

—

—

14

14.

Turn power on and wait several sec before proceeding to next step.

—

—

15

15.

Check hot surface ignitor. To do this, put setup switch SW-6 for COMPONENT TEST in ON posi-

tion. Does ignitor glow orange/white hot by end of 15-sec warm-up period?

20

16

—

16.

Disconnect PL4 from furnace control board. Connect an AC voltmeter across PL4-1 and PL4-2 on

furnace control board. Repeat COMPONENT TEST by turning setup switch SW-6 OFF and then

back ON. Do you see 120 vac across PL4-1 and PL4-2 during 15-sec warm-up period?

18

17

—

17.

Replace furnace control board.

—

—

12

18.

Check continuity in harness and ignitor. Replace defective component.

—

—

19

19.

Fix problem.

—

—

8

20.

Put setup switch SW-6 for COMPONENT TEST in OFF position.

—

—

21

21.

Jumper R and W/W1 thermostat terminals on furnace control board.

—

—

22

22.

Connect an AC voltmeter across BLUE and GREEN wires to gas valve GV. Does gas valve GV re-

ceive 24v?

26

23

—

23.

Turn power off.

—

—

24

24.

Do you have continuity across the following connections:

• PL1-2 and BLUE wire at gas valve GV.

• PL1-7 and GREEN wire at gas valve GV.

17

25

—

25.

The BLUE or GREEN wire from furnace control board to gas valve GV is not making good connec-

tion. Repair wire(s) or replace harness.

—

—

12

26.

Does gas valve open and allow gas to flow?

28

27

—

27.

Are all manual gas cocks in ON position?

11

19

—

28.

Do main burners ignite?

30

29

—

29.

Check for the following:

• Inadequate flame carryover or rough ignition.

• Low inlet gas pressure.

—

—

19

30.

Do main burners stay on?

40

31

—

31.

Turn power off and disconnect jumper wire across R and W/W1 thermostat terminals.

—

—

32

32.

Connect a DC microammeter in series with flame sensor wire.

—

—

33

33.

Turn power on and wait several sec then jumper R and W/W1 thermostat terminals on furnace con-

trol board.

—

—

34

34.

Is DC current below 0.5 microamps?

36

35

—

35.

Check connections and recheck current. If current is near typical value and control will not stay on,

replace furnace control board.

—

—

12

36.

Clean flame sensor with fine sandpaper and recheck current. Current is typically 4.0 to 6.0 micro-

amps.

—

—

37

37.

Is current near typical value?

39

38

—

38.

Replace electrode.

—

—

12

39.

Will main burners ignite and stay on?

12

17

—

40.

Do you have combustion pulsations?

41

47

—

26