Fault code 32 – Carrier 58MVP User Manual

Page 23

Fault Code 32

LOW-PRESSURE SWITCH FAULT—This fault can occur under the scenarios shown below. Keep in mind that

whenever the furnace control board shuts unit down, gas shuts off immediately, inducer continues running

for 15 sec, and if blower is running it remains running at low-heat speed or reduces to low-heat speed for

selected off delay.

•

On propane installations when low gas pressure switch LGPS is open due to switch failure or low propane line pressure.

•

CALL FOR HEAT—If low-pressure switch LPS is made when a call for heat is initiated, furnace control board flashes Fault Code 32 until

switch opens, then cycle begins.

•

LOW HEAT

1. PREPURGE—If low-pressure switch LPS does not make within 45 sec after call for heat is initiated, furnace control board starts flashing

Fault Code 32, shuts unit down, waits 2 minutes, stops flashing Fault Code 32, and restarts heating cycle.

If low-pressure switch LPS opens before ignition, furnace control board starts flashing Fault Code 32 and ramps inducer RPM up until

low-pressure switch LPS remakes. When low-pressure switch LPS remakes, furnace control board stops flashing Fault Code 32 and

continues heating cycle. If low-pressure switch LPS does not remake within 45 sec after opening, furnace control board continues flashing

Fault Code 32, shuts unit down, waits 2 minutes, stops flashing Fault Code 32, and restarts heating cycle.

2. STEADY-STATE—If low-pressure switch LPS opens during low heat, furnace control board starts flashing Fault Code 32, shuts unit

down, waits 2 minutes, stops flashing Fault Code 32, and restarts heating cycle.

•

HIGH HEAT

1. PREPURGE—If low-pressure switch LPS does not make within 45 sec after call for heat is initiated, furnace control board starts flashing

Fault Code 32, shuts unit down, waits 2 minutes, stops flashing Fault Code 32, and restarts heating cycle.

If low-pressure switch LPS opens before ignition, furnace control board starts flashing Fault Code 32, shuts unit down, waits 2 minutes,

stops flashing Fault Code 32, and restarts heating cycle.

2. STEADY-STATE—If low-pressure switch LPS opens during high heat, furnace control board starts flashing Fault Code 32, shuts unit

down, waits 2 minutes, stops flashing Fault Code 32, and restarts heating cycle.

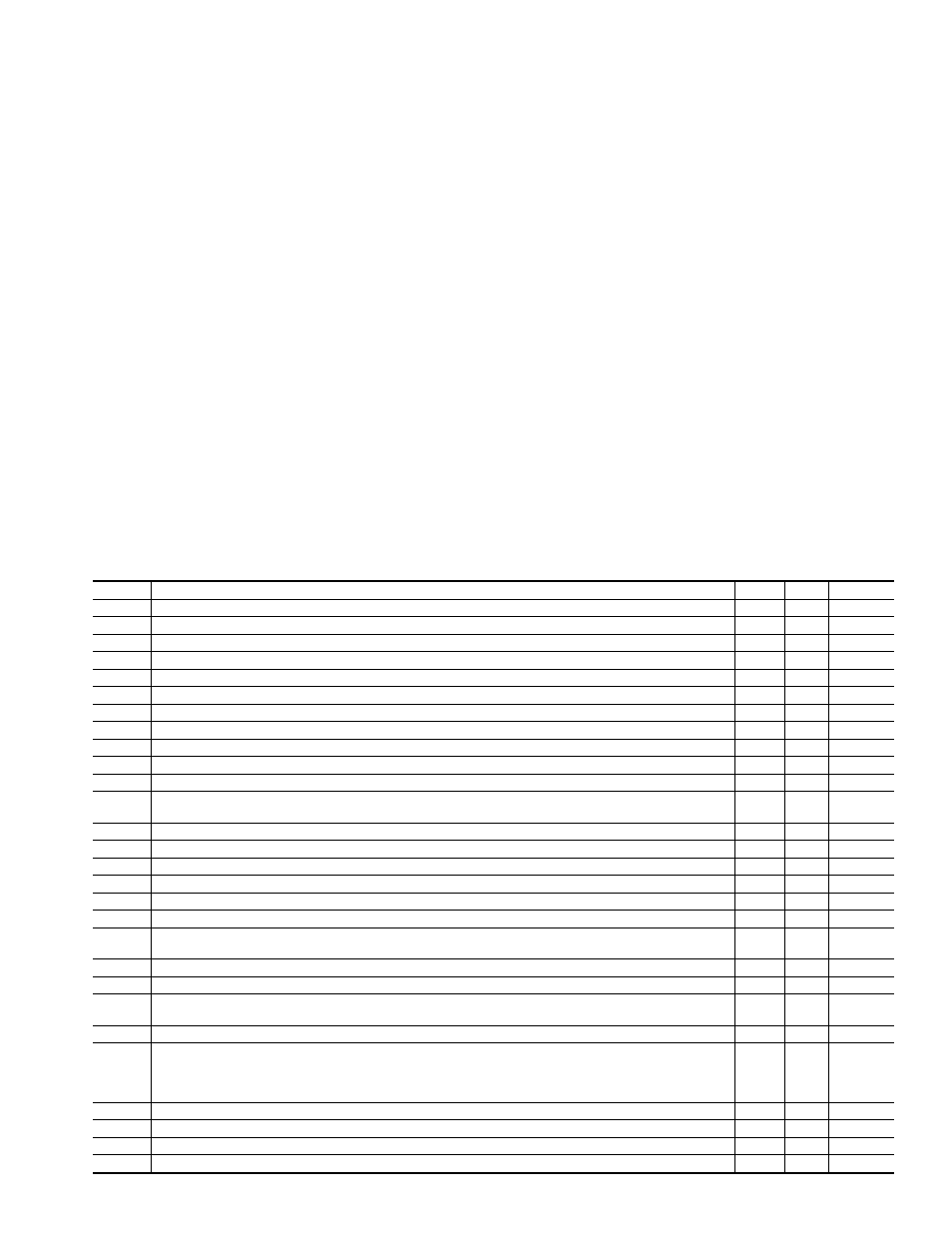

STEP

ACTION

YES

NO

GO TO

1.

Turn power off, remove blower access panel, and disconnect R thermostat lead.

—

—

2

2.

Turn power on and depress door switch. Use a piece of tape to hold switch closed.

—

—

3

3.

Is inducer motor MTR1 running?

4

5

—

4.

Are inducer motor MTR1 and blower motor MTR2 running?

13

49

—

5.

Jumper R and W/W1 thermostat terminals on furnace control board.

—

—

6

6.

Observe operation of furnace through 1 heating cycle.

—

—

7

7.

Does fault occur again?

11

8

—

8.

Does a different fault occur?

9

10

—

9.

Go to page number indicated in Index for fault code flashed.

—

—

INDEX

10.

Go to page number indicated in Index for CLEANUP AND STARTUP INSTRUCTIONS.

—

—

INDEX

11.

Does fault occur within 5 sec after a call for heat?

12

17

—

12.

Do you have 24v between N.O. (Normally Open) contact on low-pressure switch LPS and Com on

furnace control board?

14

47

—

13.

Replace furnace control board.

—

—

10

14.

Is low-pressure switch LPS wired correctly?

16

15

—

15.

Rewire low-pressure switch LPS per wiring diagram.

—

—

10

16.

Replace pressure switch assembly.

—

—

10

17.

At start of cycle as inducer is ramping up, does low-pressure switch LPS make then break?

34

18

—

→

18.

Does fault occur after ignition but before the blower comes on?

55

54

—

19.

Do you have 24v between C (Common) on low-pressure switch LPS and Com on furnace control

board?

24

20

—

20.

Do you have 24v between connector terminal PL2-1 and Com on furnace control board?

21

13

—

21.

Turn power off.

—

—

22

22.

Double check continuity between C (Common) on low-pressure switch LPS and connector terminal

PL2-1.

—

—

23

23.

The YELLOW wire to low-pressure switch LPS is not making good connection. Repair or replace it.

—

—

10

24.

Do you have at least 0.95 in. wc pressure drop (0.75 in. wc on trophy unit) across heat exchangers

when fault occurs? Determine this by connecting 1 side of a slope manometer with a tee to collector

box pressure tap. Connect other side with a tee to gas valve air pressure fitting. Refer to pressure

check diagram in Appendix C.

35

25

—

25.

Is inducer motor MTR1 rotating in direction indicated on inducer housing?

28

26

—

26.

Replace inducer motor or inducer motor assembly.

—

—

10

27.

Fix problem.

—

—

10

28.

Turn power off.

—

—

29

23

→