Carrier 58MVP User Manual

Page 22

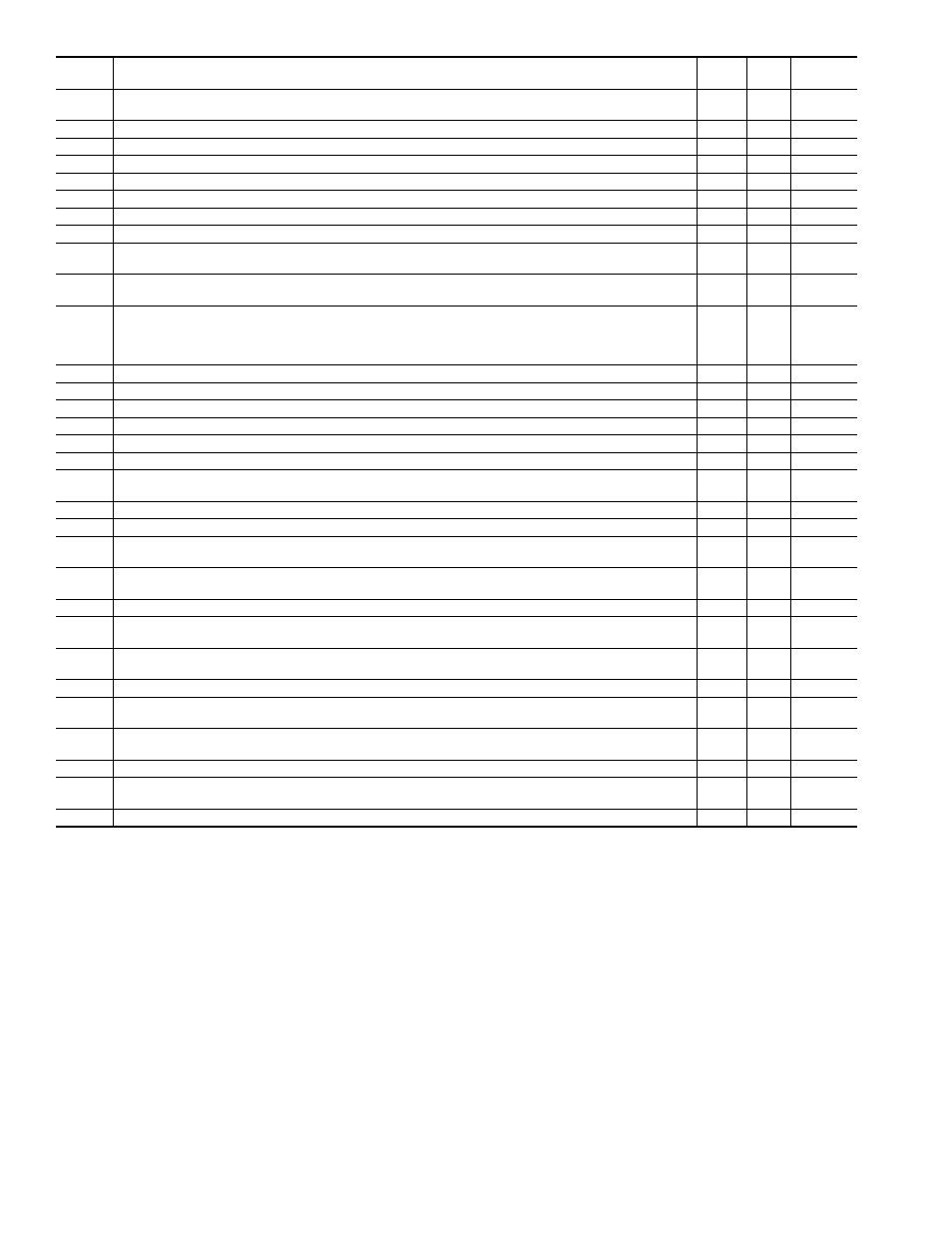

25.

Connect 1 side of a slope manometer with a tee to collector box pressure tap. Connect other side

with a tee to gas valve air pressure fitting. Refer to pressure check diagram in Appendix C.

—

—

26

26.

Turn power on and wait several sec, then jumper R and W/W1 thermostat terminals on furnace con-

trol board.

—

—

27

27.

Monitor slope manometer. Does pressure reading appear to be stable when fault occurs?

14

28

—

28.

Check for a sag in vent pipe. If problem persists, replace inducer motor.

—

—

8

29.

Disconnect jumper wire across R and W/W1 thermostat terminals and wait until blower stops.

—

—

30

30.

Jumper R, W/W1, and W2 thermostat terminals on furnace control board.

—

—

31

31.

Does high-pressure switch HPS make, then break several times at start of cycle before faulting out?

32

33

—

32.

The problem is either a sag in vent pipe or a clogged drain trap or line.

—

—

17

33.

Does fault occur before main burners ignite?

34

51

—

34.

Do you have 24v between C (Common) on high-pressure switch HPS and Com on furnace control

board?

36

35

—

35.

The YELLOW wire to high-pressure switch HPS is not making good connection. Repair or replace

it.

—

—

8

36.

Do you have at least 1.90 in. wc pressure drop across heat exchangers when fault occurs? Deter-

mine this by connecting 1 side of slope manometer with a tee to collector box pressure tap. Con-

nect other side with a tee to gas valve air pressure fitting. Refer to pressure check diagram in Ap-

pendix C.

45

37

—

37.

Is inducer motor MTR1 rotating in direction indicated on inducer housing?

39

38

—

38.

Replace inducer motor or inducer motor assembly.

—

—

8

39.

Turn power off.

—

—

40

40.

Is inducer wheel okay?

42

41

—

41.

If possible, replace inducer wheel. Otherwise, replace inducer motor assembly.

—

—

8

42.

Is there any frost build-up on combustion-air inlet?

43

44

—

43.

The problem is caused by reversed vent and combustion-air pipes or some other moist air entering

combustion-air pipe.

—

—

17

44.

You have excessive restriction in combustion-air or vent pipe.

—

—

8

45.

Turn power off and disconnect jumper wire across R, W/W1, and W2 thermostat terminals.

—

—

46

46.

Turn power on and wait several sec, then jumper R, W/W1, and W2 thermostat terminals on fur-

nace control board.

—

—

47

47.

Do you have 24v between connector terminal PL2-4 and Com on furnace control board when fault

occurs?

11

48

—

48.

Turn power off.

—

—

49

49.

Do you have continuity across terminal PL2-4 and N.O. (Normally Open) contact on high-pressure

switch HPS?

14

50

—

50.

The BROWN wire from high-pressure switch HPS to furnace control board is not making good con-

nection. Repair wire or replace harness.

—

—

8

51.

Turn power off and disconnect jumper wire across R, W/W1, and W2 thermostat terminals.

—

—

52

52.

Connect 1 side of a slope manometer with a tee to collector box pressure tap. Connect other side

with a tee to gas valve air pressure fitting. Refer to pressure check diagram in Appendix C.

—

—

53

53.

Turn power on and wait several sec, then jumper R, W/W1, and W2 thermostat terminals on fur-

nace control board.

—

—

54

54.

Monitor slope manometer. Does pressure reading appear to be stable when fault occurs?

55

56

—

55.

Replace pressure switch assembly. If problem persists, check wiring for an intermittent connection

in high-pressure switch HPS circuit.

—

—

8

56.

Check for a sag in vent pipe. If problem persists, replace inducer motor.

—

—

8

22