Appendix e – Carrier 58MVP User Manual

Page 40

Appendix E

Variable-Speed Condensing Furnace Duct Static and Blower

Operation

This variable-speed furnace has an Integrated Control and Motor called an ICM. This ICM is controlled as stated in Sequence of Operation

section. This furnace does a good job compensating for an improperly sized duct system, but this ICM is not a fix for all bad ductwork.

This troubleshooting guide has shown that the blower does a calibration 20 sec at start of any operation of ICM. Note that blower calibration

sequence is different when setup switch SW-5 is turned ON for multi-zone operation. (See Sequence of Operation section.) These blower

calibrations help to ensure proper airflow in heating and cooling. In heating mode, this calibration helps ensure proper temperature rise which

prolongs life of heat exchanger. In cooling mode, this calibration helps ensure proper CFM per ton of cooling.

If furnace is on a call for heat or cooling and duct static is too high, ICM tries to overcome external static pressure. If duct static is excessive,

ICM RPM will be out of range and a Fault Code 44 will flash on circuit board. The ICM RPM range is 250 to 1300 RPM as stated in Fault

Code 44 troubleshooting section. To check for excessive static pressure, use the following Air Delivery Curves and Duct Static Check Sheet

later in this Appendix.

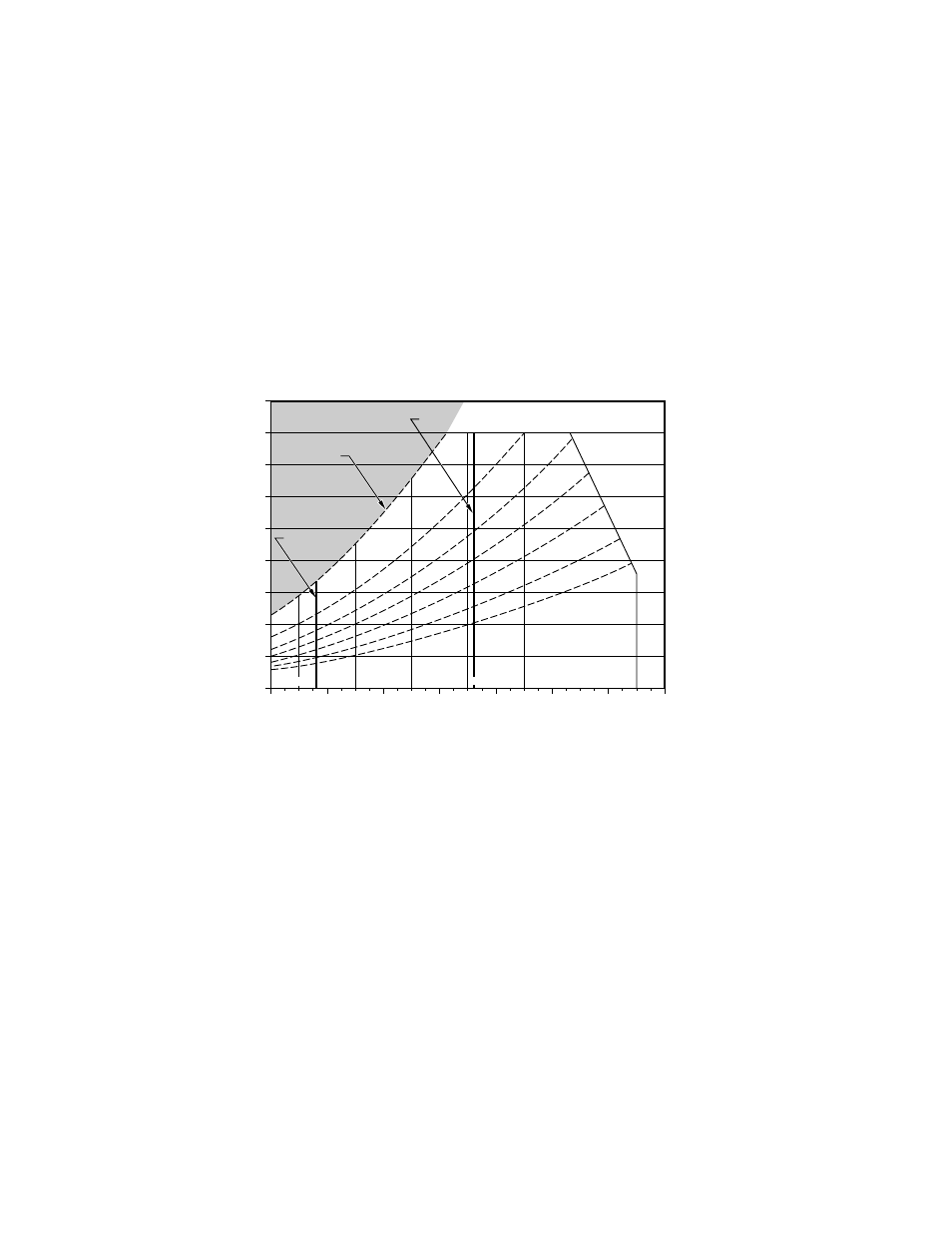

EXAMPLE: Furnace is a 100,000 Btuh input with a 5 ton blower cooling capacity. We measured total external static pressure (ESP) to be 0.4

in. wc in low-heat operation.

Use the dashed lines as guide lines. As you can see, the 0.4 in. wc total ESP is in the shaded area. The unit can deliver low heat, but as you

follow the dashed guide lines, you see that they do not cross the high-heat line until it is off the chart, somewhere above 1.0 in. wc. The furnaces

are rated at 0.5 in. wc total ESP and are tested to 0.8 in. wc total ESP.

See Static Pressure Reading Location Diagrams later in this Appendix for proper static reading locations. When checking total ESP, you must

have blower operation without a Fault Code 44 occurring. If you have a Fault Code 44 in cooling and your setting is at 5 tons, set A/C tonnage

to 4 tons and see if the Fault Code 44 goes away. If it does not, set switches to 3 tons, and so on until the Fault Code 44 goes away.

NOTE:

When adjusting airflow, you must either turn power off or terminate thermostat call after every airflow adjustment. Record all static

readings on Duct Static Check Sheet.

Solutions:

1. Dirty filter.

2. Plugged evaporator coil.

3. Re-size ductwork and/or layout.

SPECIAL NOTE: In zoning applications, it is recommended that when zone controls are applied, duct system be designed for sum of the peaks

plus 25% oversize to allow furnace to operate within its design parameters. Contact your distributor for further details.

A98451

0.8

0.7

0.6

0.5

0.4

0.3

Constant System

Curves

External Static Pressure (in. wc)

3 Ton

3

1

⁄

2

Ton

2

1

⁄

2

Ton

0.2

0.1

0

700

900

CFM

1100

1300

1500

1700

1900

2100

4 Ton

5 Ton

HIGH

HEAT

LOW

HEAT

2 Ton

*

EXAMPLE AIR DELIVERY CURVE — 060100

40