Appendix d, Quick motor test procedure – Carrier 58MVP User Manual

Page 37

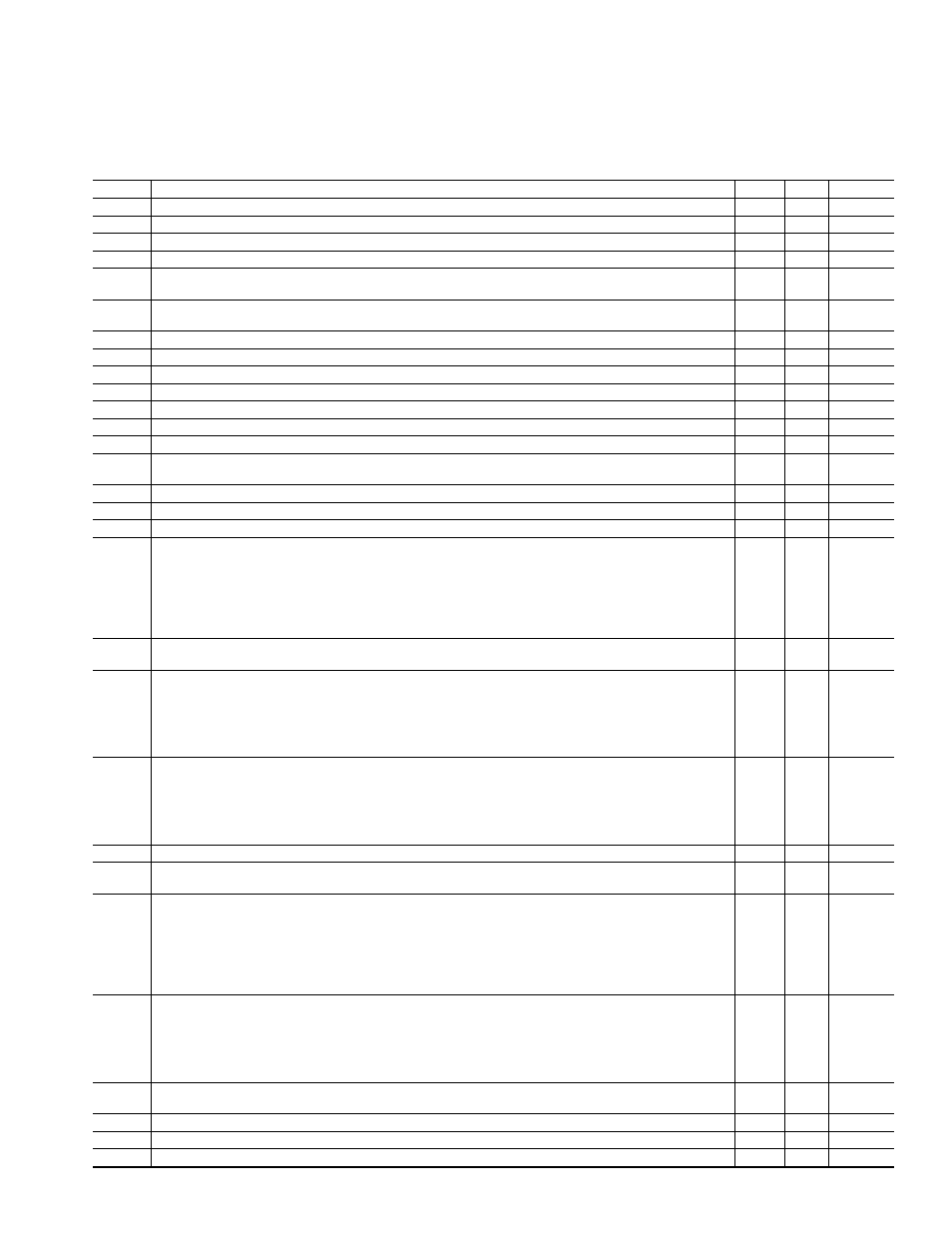

Appendix D

Quick Motor Test Procedure

In an effort to provide a method of troubleshooting inducer and blower motor by themselves, the following procedure may save you some time

in the event any of the following fault codes are the reason for service call (12, 32, 41, 42, or 44). If you get any other fault code, you should

use main troubleshooting guide to isolate problem.

STEP

ACTION

YES

NO

GO TO

1.

Turn power off, remove blower access panel, and disconnect R thermostat lead.

—

—

2

2.

Turn power on and depress door switch. Use a piece of tape to hold switch closed.

—

—

3

3.

Put setup switch SW-6 for COMPONENT TEST in ON position.

—

—

4

4.

After COMPONENT TEST is completed, does Fault Code 11 flash?

5

8

—

5.

Turn power off, put setup switch SW-6 for COMPONENT TEST in OFF position, and reconnect R

thermostat lead to furnace control board.

—

—

6

6.

Replace blower access panel and turn power on. Wait a few sec, then reset thermostat. Observe

operation of furnace through 1 heating cycle.

—

—

7

7.

Go to page number indicated in Index for START HERE section.

—

—

INDEX

8.

Does Fault Code 42 flash?

9

27

—

9.

Does inducer motor MTR1 turn on and come up to speed?

24

10

—

10.

Does inducer wheel rub against inducer housing?

16

11

—

11.

Does inducer wheel turn freely?

12

19

—

12.

Do you have 120v between

I

1 and

I

2 on furnace control board?

13

16

—

13.

Do you have 120v between terminals PL7-6 and PL7-12?

15

14

—

14.

You have an open wire or bad terminal on either the BLACK or WHITE wire between furnace con-

trol board and inducer motor MTR1.

—

—

16

15.

Are all pins and wire leads intact on connectors between furnace control board and inducer motor?

18

16

—

16.

Fix problem.

—

—

17

17.

Go to page number indicated in Index for CLEANUP AND START-UP INSTRUCTIONS.

—

—

INDEX

18.

Check Inducer PW line. To do this, connect a DC voltmeter across terminals PL7-2 BROWN (+)

and PL7-10 YELLOW (-) on inducer motor. Repeat COMPONENT TEST by turning setup switch

SW-6 OFF and then back ON. Does voltage across PL7-2 and PL7-10 change between states as

shown below?

• State 1—OFF (-0.1 — 0.1 vdc)

• State 2—LOW (2.0 — 3.0 vdc)

• State 3—HIGH (7.0 — 8.0 vdc)

19

20

—

19.

Replace inducer motor or inducer motor assembly. Inspect electronics portion of failed motor for

water damage. If present, find source of water and fix. Check A-coil and/or humidifier.

—

—

17

20.

Disconnect PL7 from inducer motor and connect a DC voltmeter across terminals PL7-2 BROWN

(+) and PL7-10 YELLOW (-). Repeat COMPONENT TEST by turning setup switch SW-6 OFF and

then back ON. Does voltage across PL7-2 and PL7-10 change between states as shown below?

• State 1—OFF (-0.1 — 0.1 vdc)

• State 2—LOW (6.0 — 7.0 vdc)

• State 3—HIGH (10.5 — 11.5 vdc)

19

21

—

21.

Connect a DC voltmeter across terminals PL1-6 BROWN (+) and PL1-4 YELLOW (-) on furnace

control board. Repeat COMPONENT TEST by turning setup switch SW-6 OFF and then back ON.

Does voltage across PL1-6 and PL1-4 change between states as shown below?

• State 1—OFF (-0.1 — 0.1 vdc)

• State 2—LOW (6.0 — 7.0 vdc)

• State 3—HIGH (10.5 — 11.5 vdc)

23

22

—

22.

Replace furnace control board.

—

—

17

23.

You have an open wire or bad terminal on either the BROWN or YELLOW wire between connectors

PL1 and PL7. Repair it or replace main harness.

—

—

17

24.

Check RPM feedback line. To do this, connect a DC voltmeter across terminals PL7-2 BROWN (+)

and PL7-1 ORANGE (-) on inducer motor. Repeat COMPONENT TEST by turning setup switch

SW-6 OFF and then back ON. Does voltage across BROWN and ORANGE wires change between

states as shown below?

• State 1—OFF (11.5 — 12.5 vdc)

• State 2—LOW (10.2 — 11.2 vdc)

• State 3—HIGH (8.4 — 9.4 vdc)

25

19

—

25.

Connect a DC voltmeter across terminals PL1-6 BROWN (+) and PL1-5 ORANGE (-) on furnace

control board. Repeat COMPONENT TEST by turning setup switch SW-6 OFF and then back ON.

Does voltage across BROWN and ORANGE wires change between states as shown below?

• State 1—OFF (11.5 — 12.5 vdc)

• State 2—LOW (10.2 — 11.2 vdc)

• State 3—HIGH (8.4 — 9.4 vdc)

22

26

—

26.

You have an open wire or bad terminal on ORANGE wire between connectors PL1 and PL7. Repair

it or replace main harness.

—

—

17

27.

Does Fault Code 41 flash?

28

7

—

28.

Does blower motor MTR2 turn on and come up to speed?

48

29

—

29.

Remove tape from door switch and turn power off at main disconnect.

—

—

30

37