Fault code 11, Fault code 12 – Carrier 58MVP User Manual

Page 13

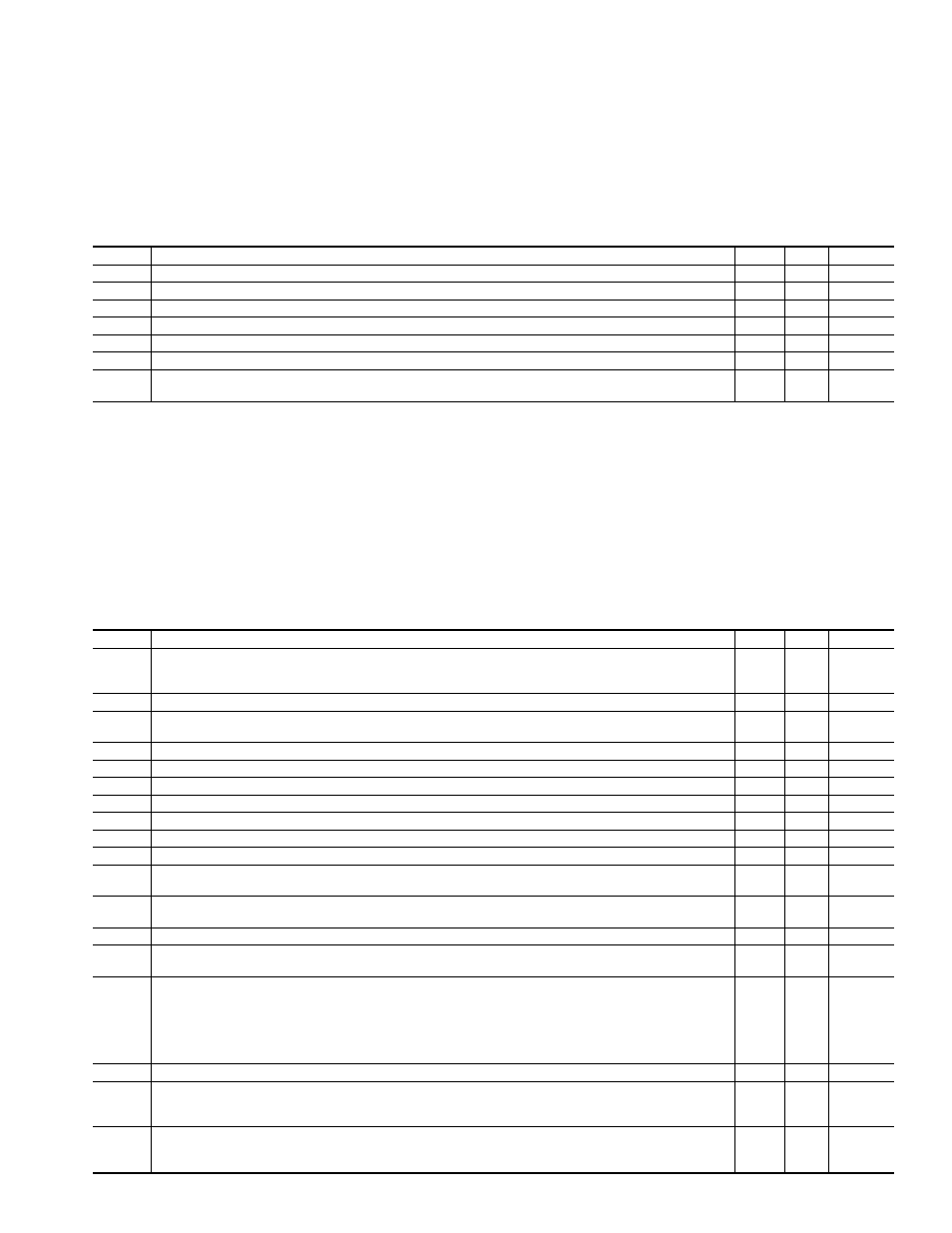

Fault Code 11

NO FAULT IN RECENT HISTORY DISPLAY—This indicates 1 of the following:

•

No faults have occurred in the last 5 previous cycles and setup switch SW-1 is in ON position.

•

The fault history can be cleared by jumpering R, W/W1, and Y/Y2 thermostat leads simultaneously while setup switch SW-1 is in ON

position.

•

Component test was successfully completed and setup switch SW-6 is in ON position.

STEP

ACTION

YES

NO

GO TO

1.

Remove blower access panel and depress door switch. Use a piece of tape to hold switch closed.

—

—

2

2.

Is setup switch SW-1 in ON position?

3

5

—

3.

Put setup switch SW-1 in OFF position.

—

—

4

4.

Go to page number indicated in Index for CLEANUP AND START-UP INSTRUCTIONS.

—

—

INDEX

5.

Is setup switch SW-6 in ON position.

6

7

—

6.

Put setup switch SW-6 in OFF position.

—

—

4

7.

Jiggle setup switches SW-1 and SW-6 back and forth. If Fault Code 11 continues to flash, replace

furnace control board.

—

—

4

Fault Code 12

BLOWER CALIBRATION LOCKOUT—This fault indicates that blower motor speed calculated for low heat is

either less than 250 RPM or greater than 1300 RPM on 2 successive attempts at calibration. Control will

auto-reset in 3 hours.

STEP

ACTION

YES

NO

GO TO

1.

Turn power off, wait 30 sec, and then restore power. Reset thermostat. Observe operation of fur-

nace through 1 heating cycle.

NOTE: Blower access panel must be in place.

—

—

2

2.

Does only Fault Code 44 flash?

40

6

—

3.

The problem is excessive restriction in the air delivery system. Check filters and ductwork. Use Ap-

pendix E to evaluate.

—

—

4

4.

Fix problem.

—

—

5

5.

Go to page number indicated in Index for CLEANUP AND START-UP INSTRUCTIONS.

—

—

INDEX

6.

Does Fault Code 44 flash twice followed by Fault Code 41?

9

7

—

7.

Does a different fault occur?

8

39

—

8.

Go to page number indicated in Index for fault code flashed.

—

—

INDEX

9.

Turn power off and remove blower access panel.

—

—

10

10.

Are all pins and wire leads intact on connectors between furnace control board and blower motor.

11

4

—

11.

Depress door switch. Use a piece of tape to hold switch closed. Wait a few sec for self test before

proceeding to next step.

—

—

12

12.

Disconnect all thermostat leads from furnace control board and jumper R and W/W1 thermostat ter-

minals.

—

—

13

13.

Does blower motor turn on and come up to speed (400-500 RPM) before fault code flashes?

—

20

—

14.

Disconnect jumper wire across R and W/W1 thermostat terminals, turn power off, and then restore

power. Wait a few sec for self test before proceeding to next step.

—

—

15

15.

Check RPM feedback line. To do this, connect a DC voltmeter across terminals PL3-2 ORANGE (+)

and PL3-3 VIOLET (–), then put setup switch SW-6 for COMPONENT TEST in ON position. Does

voltage across ORANGE and VIOLET wires change between states as shown below?

• State 1—OFF (12.0—12.5 vdc)

• State 2—LOW (10.7—11.7 vdc)

• State 3—HIGH(9.7—10.7 vdc)

16

17

—

16.

Replace furnace control board.

—

—

5

17.

Connect a DC voltmeter across ORANGE (+) and VIOLET (-) wires at connector PL13, then repeat

the COMPONENT TEST by turning setup switch SW-6 OFF and then back ON. Do you see ap-

proximately the same DC voltages across ORANGE and VIOLET wires that you saw in Step 15?

18

19

—

→

18.

Replace entire blower motor or blower control module attached to the blower motor. If you replace

the blower control module go to step 44. Always inspect failed motor for water damage. If present,

find source of water and fix. Check A-coil and/or humidifier.

—

—

4

13