Temperature monitoring, Liquid phase storage, Maintenance – Taylor-Wharton CS Series User Manual

Page 17

15

CS SERIES

Temperature Monitoring

The CS SERIES Control System uses a type T thermocouple to monitor the

temperature in the vessel. The thermocouple is factory-installed near the top of

the Taylor-Wharton Cryostorage freezer vapor chamber and the temperatures are

measured at that point.

The CS SERIES Control System accommodates a second user-installed thermocouple

for temperature measurement at a secondary location. This is also a Type T

thermocouple.

The control provides a High Temperature Alarm for each thermocouple which can

be selected by the user. If the temperature exceeds the temperature alarm set point,

the status wheel flashes and an audible alarm is triggered.

Liquid Phase Storage

Liquid phase storage is normally utilized when -196 is required to maintain stored

product viability and the storage medium is adequate for storage in liquid nitrogen.

In a typical liquid phase storage system, the liquid level sensors are positioned to

maintain the liquid level at or below the top level of the inventory control system.

During operation, the upper levels of the inventory control system will at times

become exposed as the liquid level fluctuates.

Care must be taken to ensure that the liquid level remains below the bottom of the

refrigerator lid. Exposure to liquid nitrogen may result in physical damage to the lid.

Additionally, operating the refrigerator with high liquid levels characteristic of liquid

phase storage may result in turbulence during fill cycles. Caution must be exercised

if the refrigerator lid is opened during a fill, and appropriate safety equipment

should always be worn.

The Taylor-Wharton Cryostorage Systems are set at factory for vapor phase storage.

Maintenance

To insure proper operation and maintain excellent performance of the Taylor-

Wharton Cryostorage freezer, an annual maintenance schedule should be followed

for the CS SERIES Control System. This would include the following:

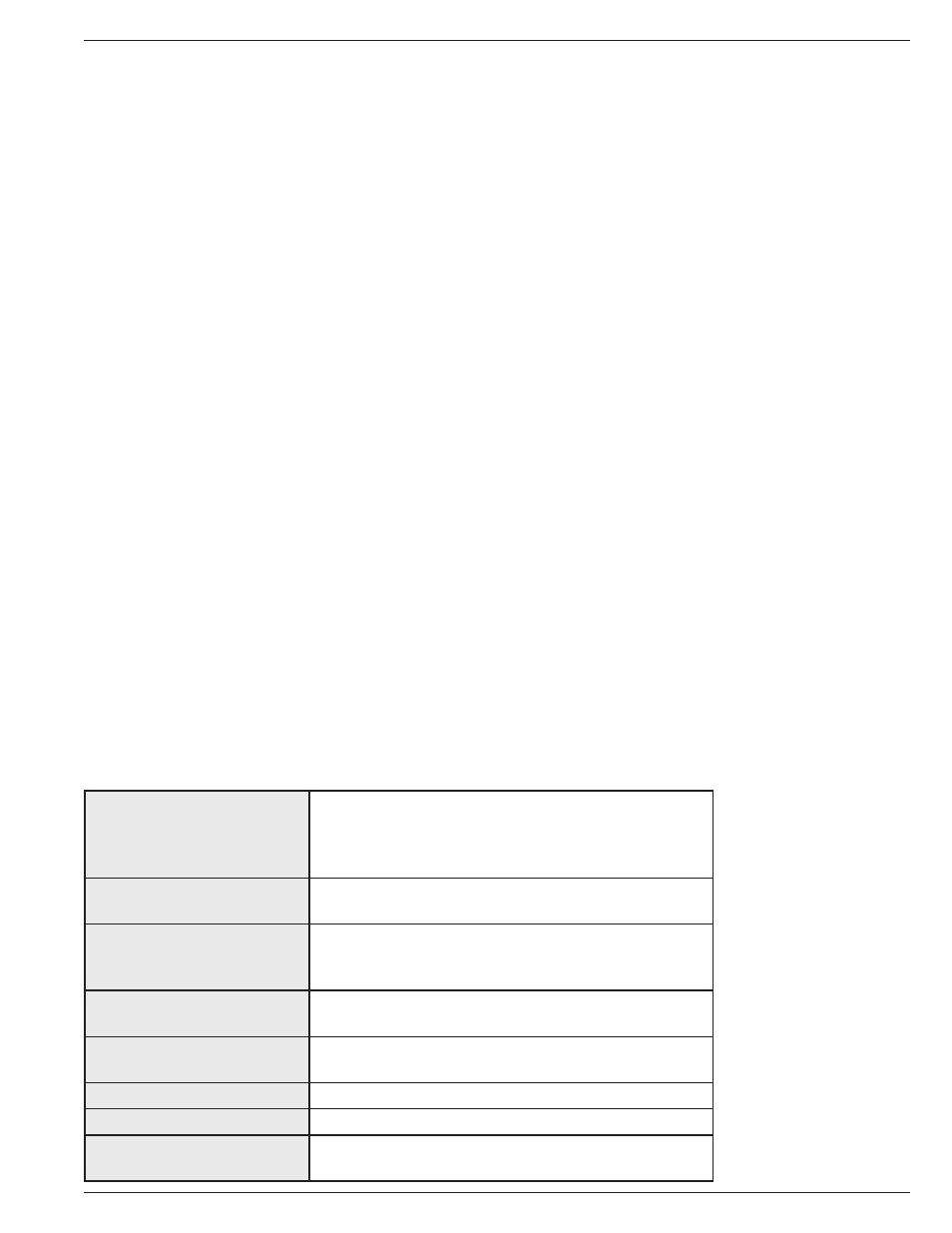

Table 3.0 Annual Maintenance Schedule

CS SERIES Control

System

Examine for exposure to moisture, wear and tear,

connector problems, and cracks or other damages

to the faceplate or buttons. In addition, periodic

firmware updates may be important.

Harness Assembly

Examine for damage to the cable and damage to

connectors.

Battery

Examine connection cable and connector for

damage.Examine vinyl cover for damage.

Replace every 2 years.

Solenoid Valve

Examine wires and connector for damage.

Replace every 3 years.

Lid Switch

Examine lid switch pickup and wires for damage.

Replace if necessary.

Level Sensor Assembly

Examine for damage to wires and connector.

Thermocouple Assembly Examine for damage to wires and connector.

Power Supply

Examine for damage to power supply and power

cords.