Important, Warning, Unpacking instructions – Qmark CDF - Commercial Downflow Ceiling Mounted Heaters User Manual

Page 2: Installation of surface mounted heater

IMPORTANT NOTICE

- This heater is wired so the fan will come

on with no delay when energized as the thermostat is calling for

heat. When the thermostat is satisfied, the fan must continue to run

until the heater has cooled to a safe temperature. If an external

thermostat or controls are to be used, DO NOT wire heater so ther-

mostat shuts power to fan. The heater will be damaged and the

warranty will be voided. Thermostat must be connected as shown

on wiring diagram (Fig. 12) for correct operation.

NOTE: Field wiring must be #10 AWG. min. rated 90°C,min.

Wiring Compartment Volume: 252in

3

(4130cm

3

)

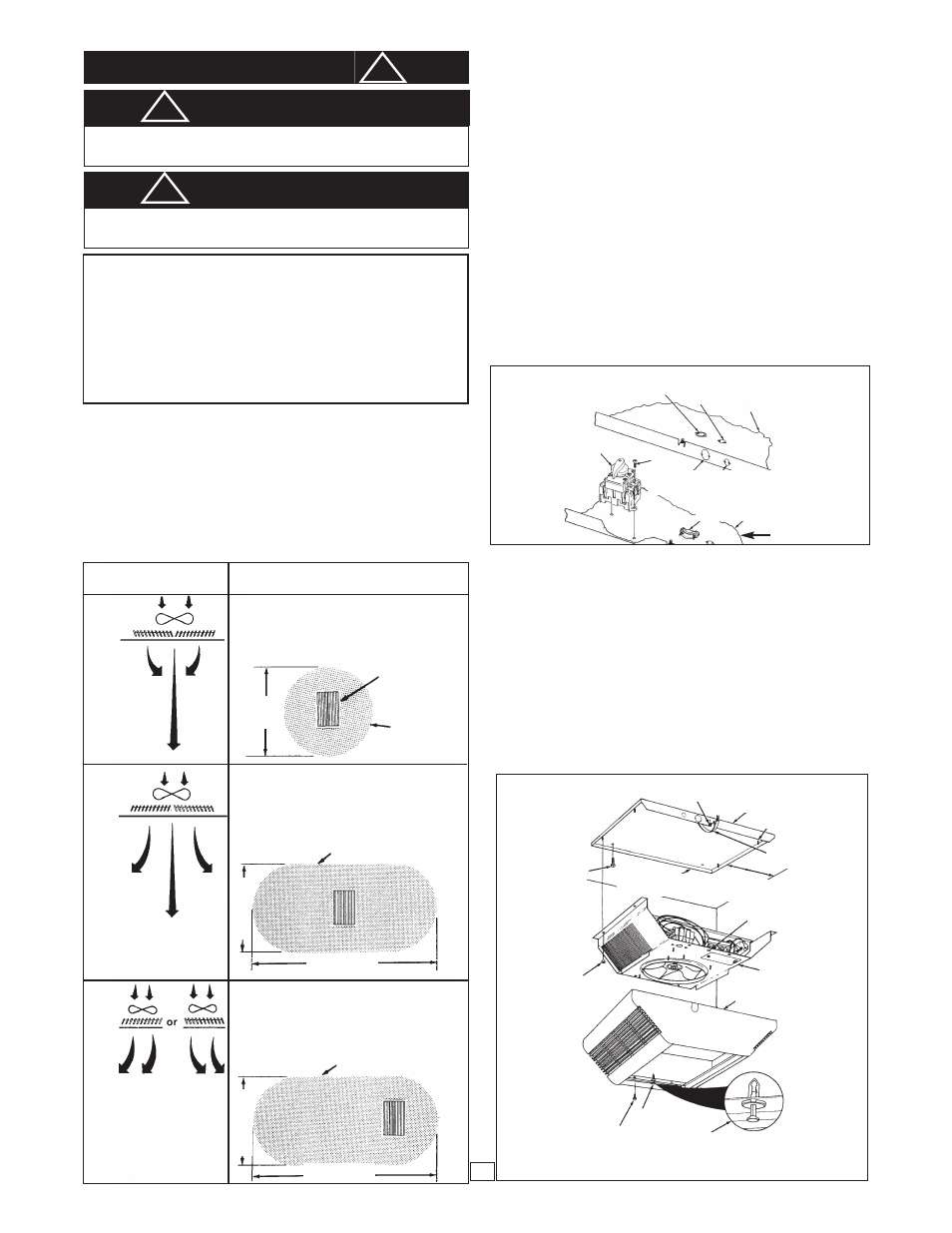

ADJUSTABLE DISCHARGE GRILLES

CUSTOM AIR FLOW PATTERNS

1. The discharge air pattern is determined by the arrange-

ment of the discharge grilles.

2. Care must be taken when selecting location of heater.

NOTE: The discharge grill area is rectangular; the discharge

grilles can only be installed parallel to the intake louvers.

UNPACKING INSTRUCTIONS

This heater is shipped in two cartons.

1. One carton contains the Heater Section, consisting of the

fan, heating elements and controls (Models 542, 547,

548, 557 & 558).

2. The other carton contains the Mounting Enclosure.

There are two types of enclosures: a) Recessed

Mounting Enclosure, Type REA and b) Surface Mounting

Enclosure, Type SEA. Either enclosure is acceptable

with any of the Model 500 Series heater sections.

Both a Heater Section and a Mounting Enclosure are

required to complete the installation of this heater.

INSTALLATION OF SURFACE MOUNTED HEATER

1. Determine the desired location of the heater. See warn-

ing No. 4 for min. mounting clearances.

2. Remove the Surface Mounting Plate (Figure 1) from the

carton containing the Surface Mounting Enclosure, Type

SEA.

3. Remove one of the knockouts and install a cable or con-

duit connector.

4. Install the optional disconnect switch (if required) as

shown in Figure 1.

5. Run the power supply cable through the connector, leav-

ing about 8” (203mm) of wire inside the surface mounting

plate. (Power supply cable must be # 10 AWG min. rated

90°C min.)

IMPORTANT

!

Field Conversion for Lower Wattage Rating

(Figure 12)

To convert the heater to a lower wattage rating, completely remove

one(1) red jumper wire from one heating element for 25% wattage

reduction. Completely remove two (2) red jumper wires for a 50%

wattage reduction. Discard the jumper(s). Be sure the remaining

wires are securely connected.

Conversion for 3Ø Installation

Heater is factory wired for connection to 1Ø only. To convert to 3Ø,

remove and discard blue jumper wire between L1 & L3. (See Fig. 12,

page 5).

Figure 1

Figure 2

WARNING

FAILURE TO INSTALL THE FOUR MOUNTING NUTS

COULD RESULT IN THE HEATER FALLING. (SEE FIG. 2)

!

WARNING

FAILURE TO INSTALL THE FOUR SCREWS, COULD ALLOW

THE SURFACE WRAPPER TO FALL. (SEE FIG. 2)

!

Discharge Air

Grille Arrangement

Custom Air

Flow Pattern

NARROW AIR PATTERN for high ceiling

applications (11’(3352mm) to 14’(4267mm)),

concentrates the heated air to ensure full pen-

etration to the floor level.

8’

(2438mm)

24’(7315mm)

17’(5181mm)

8

’(

2

4

3

8

m

m

)

1

0

’(

3

0

4

8

m

m

)

Heater

Discharge

Grilles

7/8”(22,2mm) &

1-1/8”(28.6mm)

Nested Knockout

1/2”(12.7mm)

Knockout

1/2”(12.7mm)

Knockout

Cable or conduit

connector

Optional

Disconnect Switch

Surface Mounting

Plate

7/8”(22,2mm)

Knockout

Surface

Mounting Plate

Screw (2)

Air Pattern

on Floor

Air Pattern on Floor

Air Pattern on Floor

Screws or

Bolts

(Not Supplied)

Grounding

Screw

Surface Mounting

Plate

Power Supply

Cable

Thumb Pin

Hole (2)

Thumb Pin

Hole (2)

Insure that “Thumb Pin” is pulled out

before positioning the surface wrapper on

the heater section. Depress “Thumb Pin”

after surface wrapper is sealed firmly

against the heater section.

Heater Section

Surface Wrapper

Screw (4)

12”(305mm) Min.4kw

24”(609mm) Min. 5kw

12”(305mm) Min.4kw

24”(609mm) Min. 5kw

Stud (4)

Nut (4)

WIDE AIR PATTERN for standard ceiling

applications (8’(2438mm) to 10’(3048mm)),

disperses the air to give a gentle, less pro-

nounced pattern while circulating all the air

from floor to ceiling.

ASYMMETRICAL AIR PATTERN directs

heated air in a specific direction, allowing

the heater to be located where space allows

with the heated air delivered to where it is

required.

2