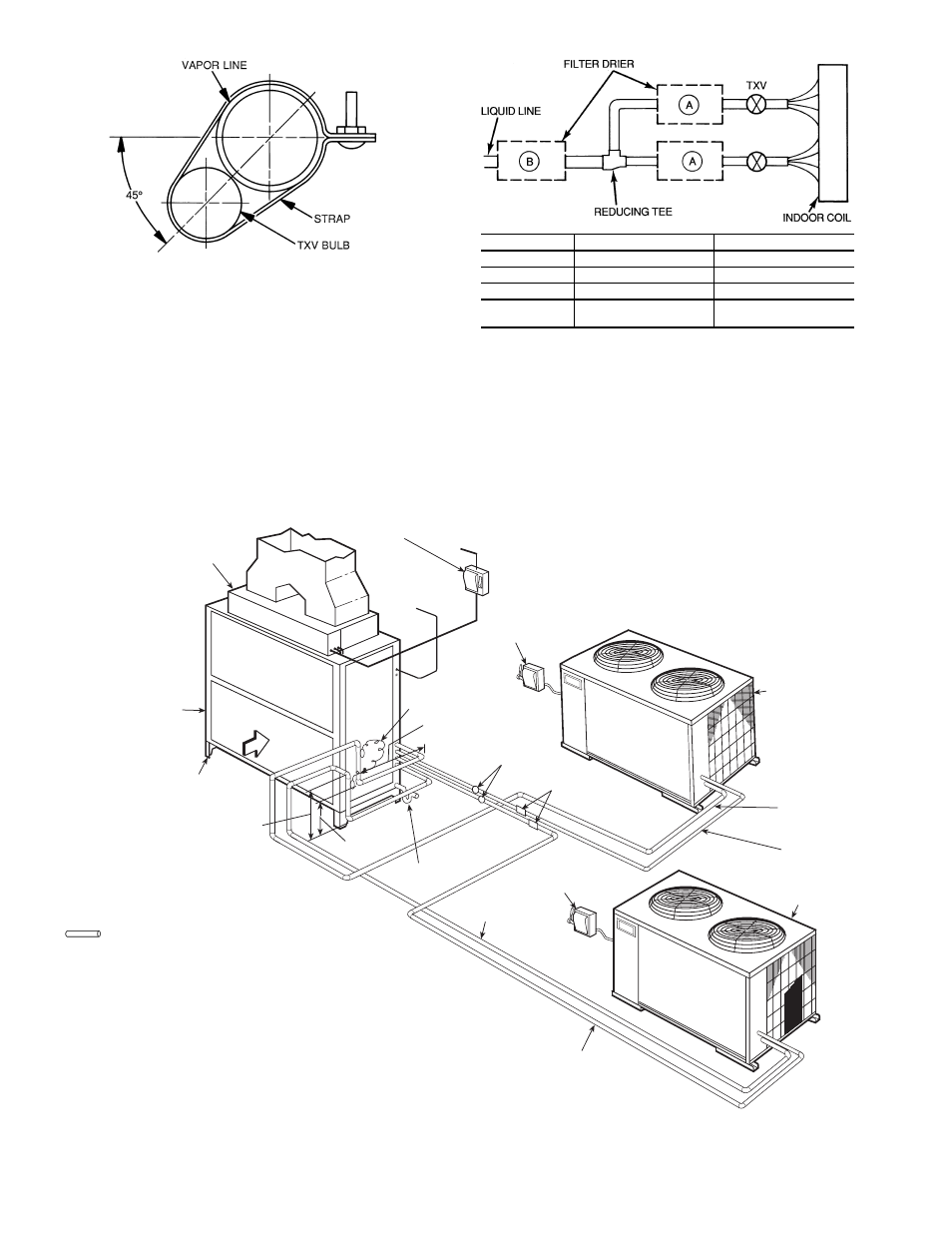

Fig. 9 — txv sensing bulb location, Fig. 11 — filter drier quantity and location – Carrier 40RMS008-034 User Manual

Page 16

16

RETURN

AIR

SUBBASE

ACCESSORY

15 DIAMS

MIN

40RMQ024

UNIT

ELECTRIC

HEATER

ACCESSORY

24 V

CONTROL

WIRE

BULB CAPILLARY

TUBES

10 DIAMS

MIN

CONDENSATE

DRAIN

8 DIAMS

MIN

DISCONNECT

PER NEC

INSULATED

VAPOR LINE

FUSED

DISCONNECT

SWITCH*

FUSED

DISCONNECT

SWITCH*

SIGHT

GLASS*

FILTER

DRIER*

INSULATED

VAPOR LINE

LIQUID

LINE

CONDENSING

UNIT A

CONDENSING

UNIT B

LIQUID

LINE

LEGEND

TXV —

Thermostatic Expansion Valve

NOTE: The 8 o’clock position is shown above.

Fig. 9 — TXV Sensing Bulb Location

LEGEND

*Field supplied.

NOTES:

1. All piping must follow standard refrigerant piping techniques. Refer to

Carrier System Design Manual for details.

2. All wiring must comply with the applicable local and national codes.

3. Wiring and piping shown are general points-of-connection guides only

and are not intended for, or to include all details for, a specific installation.

4. Filter driers must be bi-flow type suited for heat pump duty.

5. Condensing unit A should be the first on and last off and be connected to

the lower half of the coil.

6. Internal factory-supplied TXVs not shown.

NEC —

National Electrical Code

TXV —

Thermostatic Expansion Valve

Piping

Fig. 10 — Typical Installation — 40RMQ024,028

LEGEND

TXV —

Thermostatic Expansion Valve

Fig. 11 — Filter Drier Quantity and Location

UNIT

QUANTITY REQUIRED

FIGURE REFERENCE

38ARQ008,012

1

B

38AQS016

2

A

38ARQ012 (2)

2

A

38ARQ012,

AQS016

2

A