3 geogauge applications – Humboldt H-4140 GeoGauge User Manual

Page 5

5

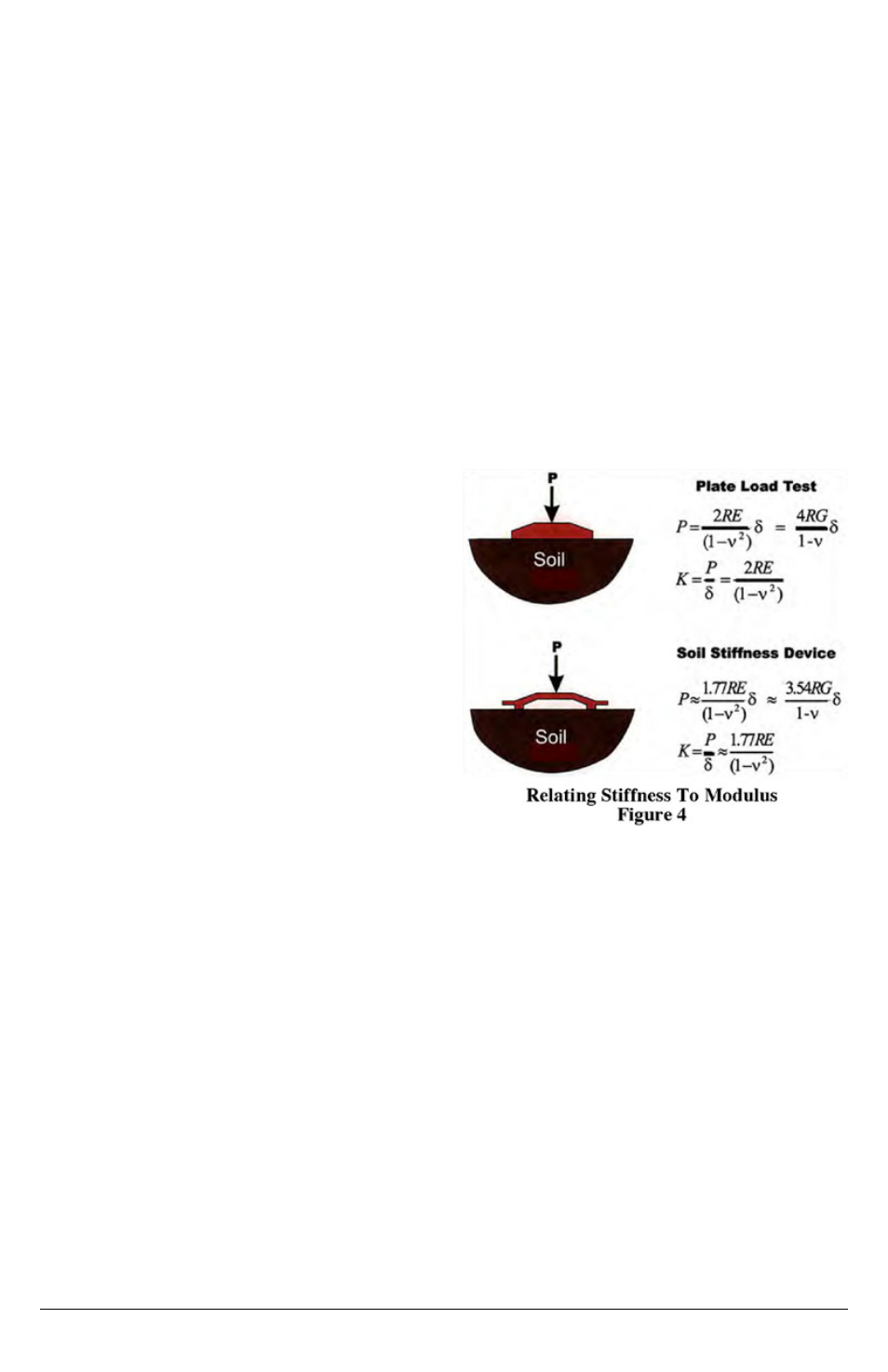

Many current methods of measuring material modulus or lift stiffness in the

field require large forces to produce a measurable deflection. The GeoGauge

uses technology borrowed from the military to measure very small deflections,

allowing much smaller loads. The GeoGauge does not measure the deflection

resulting from the GeoGauge weight. Rather, the GeoGauge vibrates, producing

small changes in force that produce small deflections. The material deflects an

amount δ, which is proportional to the outside radius of the ring foot (R), the

Young’s modulus (E), the shear modulus (G) and Poisson’s ratio (υ) of the soil

1

.

The stiffness is the ratio of the force to displacement: K=P/δ. The GeoGauge

produces soil stress and strain levels common for pavement, bedding and

foundation applications (27.58 kPa or ~ 4 psi). Young's and shear modulus can

be determined from GeoGauge measurements if a Poisson's ratio is

assumed (Fig. 4).

GeoGauge measurements intentionally mimic Resilient Modulus measurements

as much as typical site conditions

will allow. This allows GeoGauge

measurements to be related to

Resilient Modulus.

1.3: GeoGauge

®

Applications

The GeoGauge has an application

anywhere there is a need to structurally

evaluate a construction material in-

place. Following are some examples.

The GeoGauge is better suited for the

in-place QC of unbound materials than

any other available instrument for:

• In-place estimates of Resilient

Modulus

• Modulus measurements that relate well to relative compaction

• Identifying structural anomalies

• Quantifying strength gain with time

• Obtaining precise measurements

This is based on the findings of the Transportation Research Board’s National

Cooperative Research Program Project 10-65.

The GeoGauge can be used in the QC of compacted subgrades and bases. The

QC method utilizes a control strip and initially established target stiffness values

that are related to conventional relative compaction. Ultimately, target stiffness

values are related to design values and expected values based on experience

(e.g., Resilient Modulus). Appendix 1 is a case study of such a QC method.

1 Poulos, H.G., and Davis, E.H., Elastic Solutions For Soil & Rock Mechanics, 1974, page 167-168.