Humboldt H-4140 GeoGauge User Manual

Page 21

21

The Humboldt GeoGauge is a 10” diameter,

11” tall, 22 lb. electro-mechanical instrument

that when placed on the surface of the ground

evaluates the stiffness of the top 9” to 12” of

material. It vibrates the ground over a range of

discrete frequencies, applies force, measures

the resulting deflection and displays the results

in about a minute. It was chosen by MnDOT

District 2 because measurements could be made at a rate greater than the rate

of compaction, it has no licensing or safety requirements and its performance

(reliability, precision & bias) had been proven by FHWA Study 2(212) &

TRB NCHRP Project 10-65.

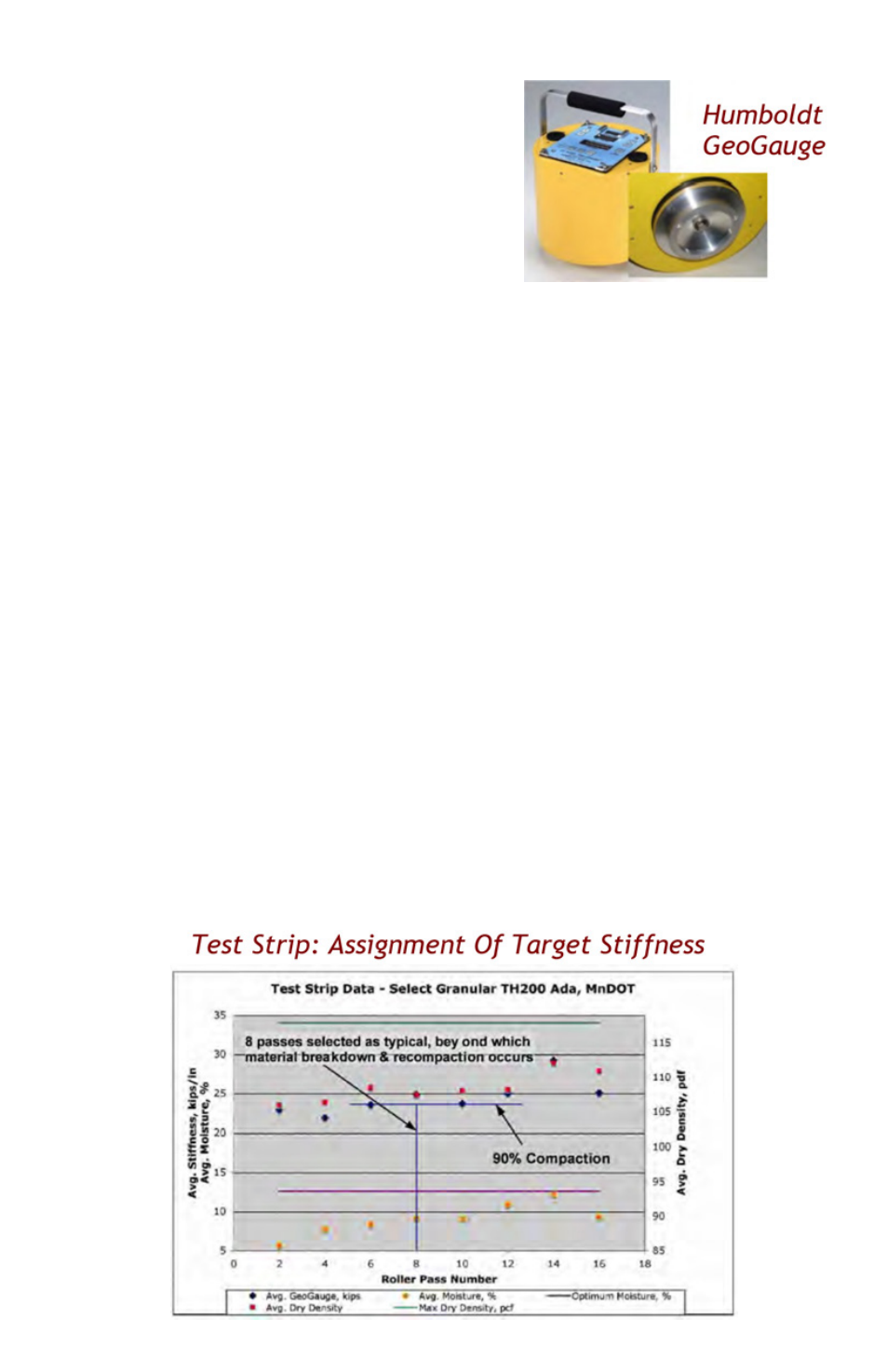

In the summer of 2004, District 2 chose road TH200 in Ada, MN for its initial

use of this QC test method. The method was contractually specified. This was

the only way District 2 thought that sufficient data could be collected for a

comprehensive evaluation of the method. The subgrade was an AASHTO A-1-b

material, placed in two 12” lifts over two miles of 2-lane roadway. Stiffness was

measure approximately every 100 ft. on each lane for each compacted lift, one

1,000 ft. section at a time. Based on test strip measurements at the start of the

project, a stiffness value of 23 klb/in was assigned as a target corresponding to

the specified 90% compaction. Moisture was measured approximately every

500 ft. by either time-domain-reflectometry or field oven. Density was measured

randomly as a check on the method and took precedence in judging quality if

there was a conflict with stiffness.

The over 1,000 stiffness QC tests made on the TH200 project indicated that the

level of compaction was from 87% to 97% (18.2 klb/in to 32.2 klb/in for 95%

of the data). This was better than the best quality traditionally possible for the

material in District 2’s experience. Moisture content was typically 3.5% below

optimum, varying from about 6% to 12%. This was consistent with the best

quality traditionally possible.