Humboldt H-4140 GeoGauge User Manual

Page 20

20

Traditional subgrade compaction QC test methods do not evaluate in-place

material strength or the structural uniformity of each lift as placed. Evaluating

these two factors is essential if cost is to be held to a minimum while assuring

the performance needed for the roadways intended function and projected

life. This type of evaluation is essential if the industry’s trend towards modulus

based mechanistic design and performance specifications for roadways are to be

supported. Also, traditional methods do not provide contractors with sufficient

real-time feedback so as to optimize the balance of quality and cost.

Accordingly, a simple and precise modulus or stiffness based QC test method

for subgrades was needed by the Minnesota Department of Transportation

(MnDOT), District 2, Thief River Falls Construction Office that would evaluate the

required factors as compaction occurs. At the same time this method needed

to provide an index of percent compaction so as to fit within the framework

of traditional specifications. Finally, the method needed to provide an index

of resilient modulus to support the future use of mechanistic design and

performance specifications.

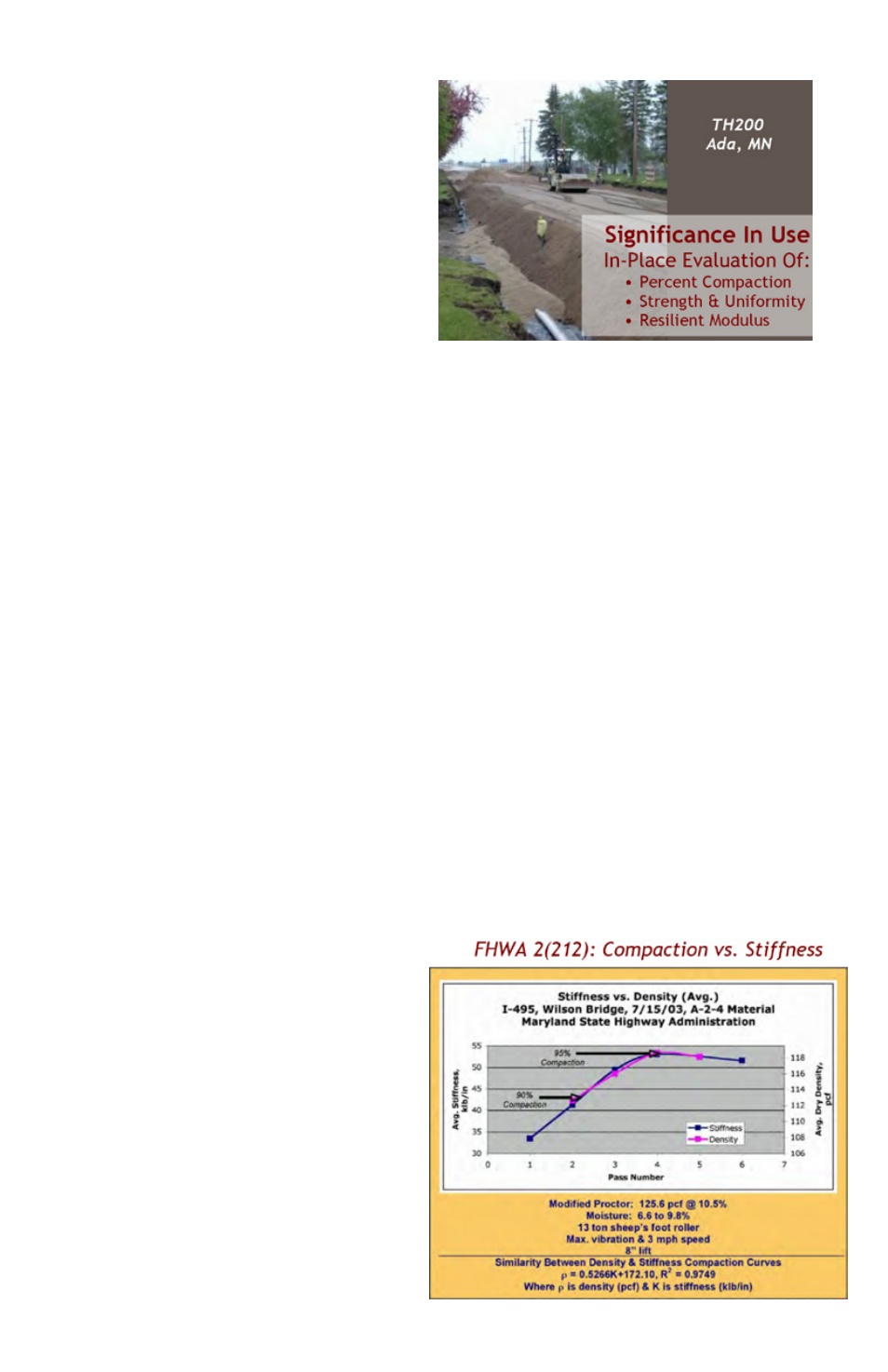

District 2 selected an in-place QC test method developed under FHWA Study

2(212) that did not interfere with or delay the construction process. Without

penetrating the ground, the method used the Humboldt GeoGauge to measure

the stiffness of each lift and thereby evaluate percent compaction. Using a

test section or strip of subgrade

material, lift stiffness at controlled

moisture content was measured

and spatially averaged as a function

of compactive effort. Initially this

data was compared to density

as a function of effort to confirm

the findings of FHWA 2(212)

that maximum stiffness occurs at

optimum compaction as constrained

by site conditions. The resulting

empirical relationship was used to

establish QC stiffness targets for the

subgrade that corresponded to the

traditionally specified levels of

percent compaction.

CASE STUDY:

Stiffness Based Compaction QC

of a Granular Subgrade

Minnesota DOT

District 2

423 West Zeh St.

Thief River Falls, MN 56721