Humboldt H-4140 GeoGauge User Manual

Page 22

22

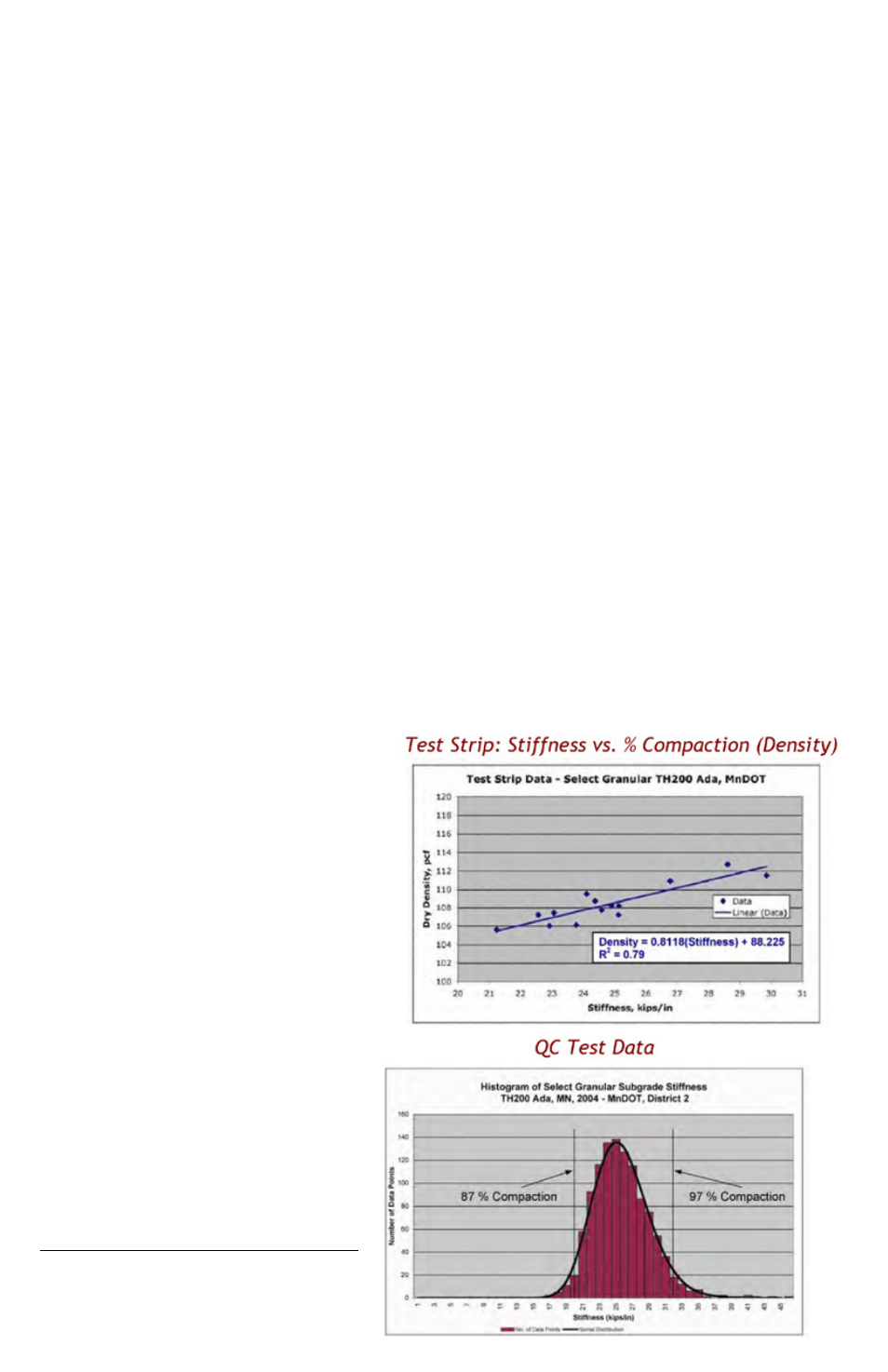

The level of material compliance with the specification and small variability in

the quality of compaction was unprecedented in the experience of MnDOT

District 2. The real-time nature of the stiffness QC tests forced the continuous

attention of the contractor to compaction quality as was evident by the section-

by-section adjustments in roller patterns and watering. This real-time attention

to quality also resulted in a significant reduction in the contractor time and effort

traditionally needed to accomplish this kind of job.

The material strength achieved and its uniformity, as evident from the stiffness

tests, was consistent with supporting a 20-year roadway life. According to FHWA

guidelines, A coefficient of variation (COV) of less than or equal to 20% in

subgrade strength will support a 20-year life. The COV achieved for TH200 was

less than 14%.

District 2 found that the material and construction uniformity enabled by this

test method was sufficient to require stiffness testing intervals of no smaller than

every 500 ft.

Since the completion of the TH200 job, the stiffness measurements made as

part of the test method has been shown to have a strong relationship to resilient

modulus and so are useable as an in-place index

1

.

District 2, Thief River Falls Construction Office, of the Minnesota Department

of Transportation has deemed the success of this first use of stiffness based

compaction QC testing sufficient to warrant continuing and broadening use of it

on subgrades and bases in the 2005 and 2006 construction seasons.

For more information contact:

Melvin Main, Humboldt Mfg. Co.

717-650-6537,

[email protected]

or

J. T. Anderson

Resident Engineer,

MnDOT District 2

216-681-0927

1 Development Of Resilient Modulus Prediction

Models For Base And Subgrade Pavement Layers

From In Situ Devices Test Results, 2004, Ravindra

Gudishala, Louisiana State University, Baton Rouge,

LA 70808