Bio-Rad Components for Older Model Spot Cutter User Manual

Page 16

Section 6

Calibration

6.1 Camera Alignment

If the cutting head is not moving to the correct position as selected using the software, the

system should be calibrated. To assess the alignment of the camera to the cutting stage,

perform the follow steps using the calibration plate (the plastic plate with a rectangle):

1. Place the calibration plate on the cutting surface.

2. Take a photo of the calibration plate.

3. Save the photo.

4. Open the photo within the SpotOn program.

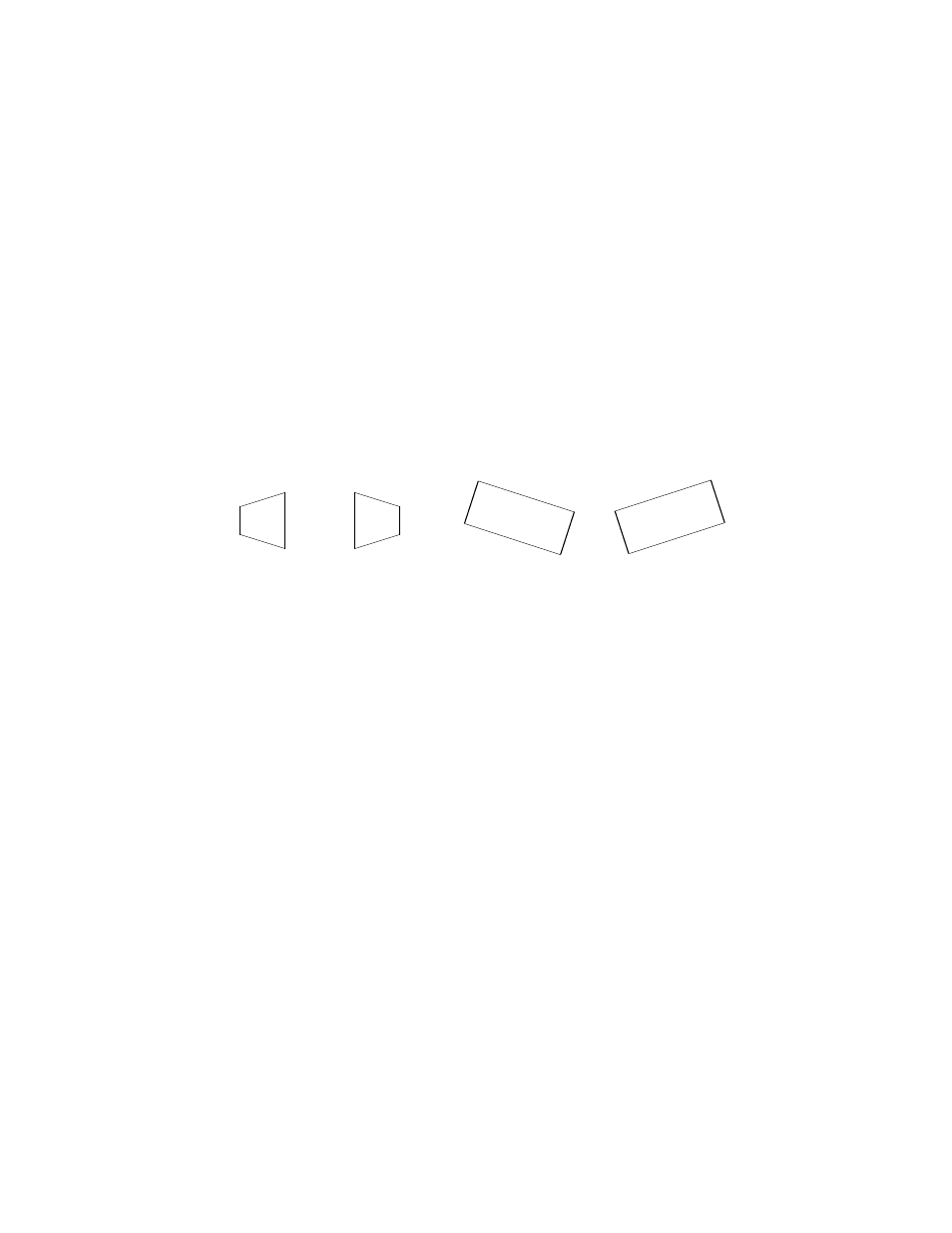

If the image of the calibration plate is not square, i.e. it appears to be generally shaped like

any of the following pictures, a-d, the camera is out of alignment and requires Bio-Rad Service

to arrange a service visit to align the camera.

a.

b.

c.

d.

If the rectangle is at right angles in the viewing screen and is accurate in its shape, but the

system is not moving to the correct x,y position, then proceed with the following calibration

routine. A copy of the System Serial Number is necessary for calibration and has been

supplied upon delivery of the system.

6.2 Calibration Definitions

Pixel Position Y (PPY) & Pixel Position X (PPX): the scale/ratio between the image on

the screen and the image in real life.

X and Y Offset: adjusts the distance between the position that the system actually moves

to, and the position that the system should have moved to. Scale: 100 units in the numbering

of X and Y Offset is equal to 1mm on the calibration plate. A four digit number is entered for

both the X and Y offset values. For every 100 digits, the system is offset 1 mm on the cutting

surface.

6.3 Calibation Procedure

1. Place the calibration plate or graph paper on the cutting surface

2. Take an image of the calibration plate or graph paper

3. Save the image

4. Open the image within the SpotOn software

5. In the Operations menu, select Others. A dialog box will appear and select Cut Without

Turn. This will allow the cutting tip to go to the selected spot without cutting or

marking the calibration template or graph paper.

6. Get a pad of paper to record coordinate locations during the calibration procedure. This

will help in zeroing in on a coordinate location.

12