Create adc driver mounts, Adc front break holes, Dc brace plate holes – Great Plains VARIABLE RATE KIT Operator Manual User Manual

Page 6: Cb a d, Er v d, Ud l r

6

Air Drill Variable Rate Kit

Great Plains Mfg., Inc.

166-263M

6/23/2010

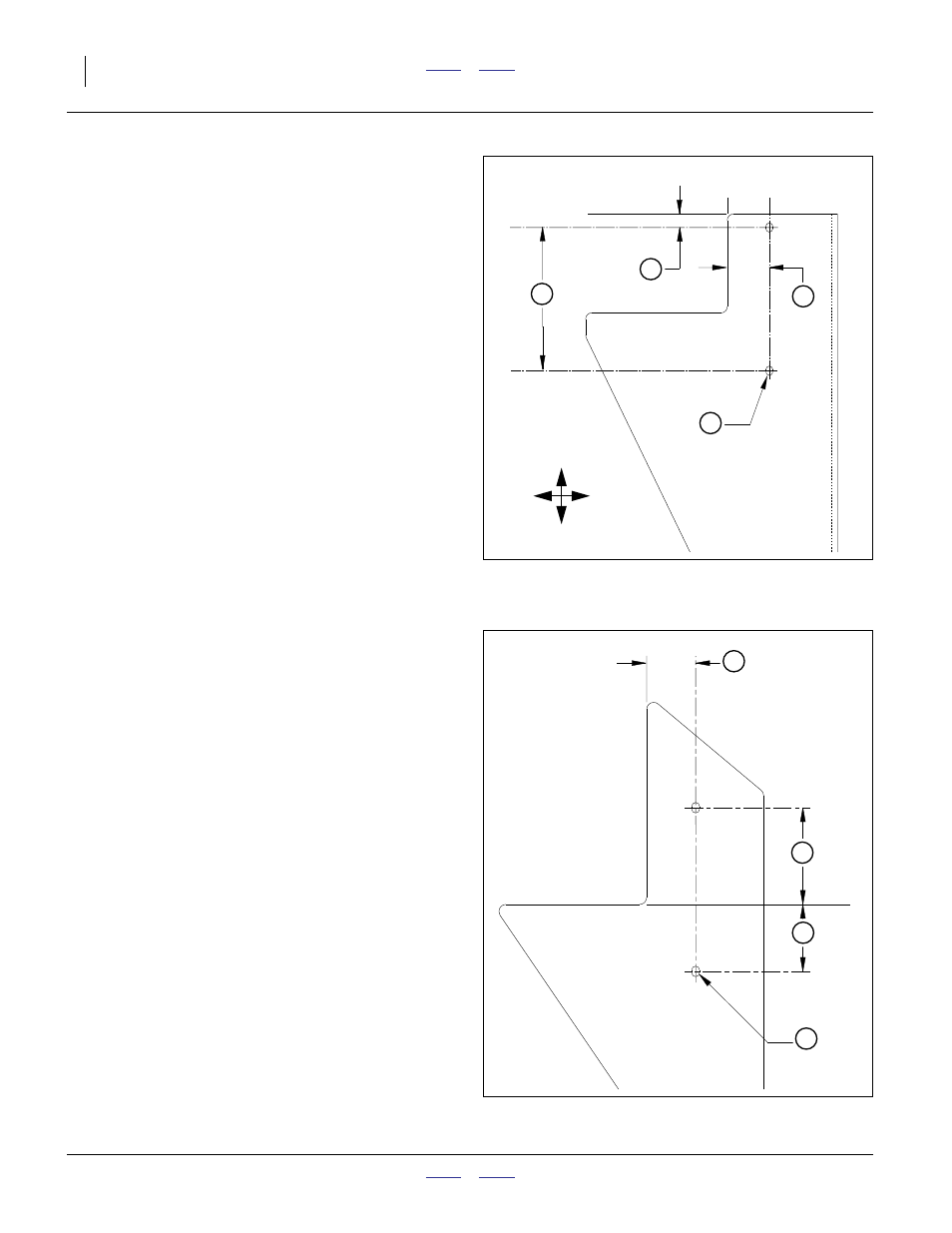

Create ADC Driver Mounts

ADC Front Break Holes

Refer to Figure 6

22. Drill and size two slotted holes in the front break of

the gearbox mount plate as follows:

If you are unable to make slotted holes, make two

circular holes 5.75 inches (14.6cm) apart.

DC Brace Plate Holes

Refer to Figure 7

23. Drill and size two slotted holes in the front break of

the gearbox mount plate as follows:

If you are unable to make slotted holes, make two

circular holes 5.75 inches (14.6cm) apart.

If you are unable to make two holes without per-

forming major disassembly of the gearbox struc-

tures, make only the top hole.

a

1

23

⁄

32

in

(1.72in)

(4.37cm)

Frame tool bar to

vertical slot center-lines

b

9

⁄

16

in

(0.55in)

(1.4cm)

Top slot center from

top of gearbox mount plate

c

5

27

⁄

32

in

(5.84in)

(14.8cm)

Slot to slot spacing,

center to center

d

9

⁄

32

x

3

⁄

8

in

(0.28 x 0.38in)

(7.1 x 95mm)

Two slots, dimensions are

horizontal x vertical

Figure 6

ADC Front Break Holes

29511

c

b

a

d

U

D

L

R

d

9

⁄

32

x

3

⁄

8

in

(0.28 x 0.38in)

(7.1 x 95mm)

Two slots, dimensions are

horizontal x vertical

e

1

3

⁄

4

in

(1.75in)

(4.4cm)

Frame tool bar to

vertical slot center-lines

r

2

25

⁄

64

in

(2.39in)

(6.1cm)

Bottom of frame tool bar to

upper slot center

v

3

29

⁄

64

in

(3.45in)

(8.8cm)

Bottom of frame tool bar to

lower center to center

r+v

5

27

⁄

64

in (5.84in)

(14.8cm)

Slot to slot spacing,

center to center

Figure 7

ADC Brace Plate Holes

29512

e

r

v

d