Prepare meters, Prepare adc driver mounts – Great Plains VARIABLE RATE KIT Operator Manual User Manual

Page 5

Great Plains Mfg., Inc.

Installation Instructions

5

6/23/2010

166-263M

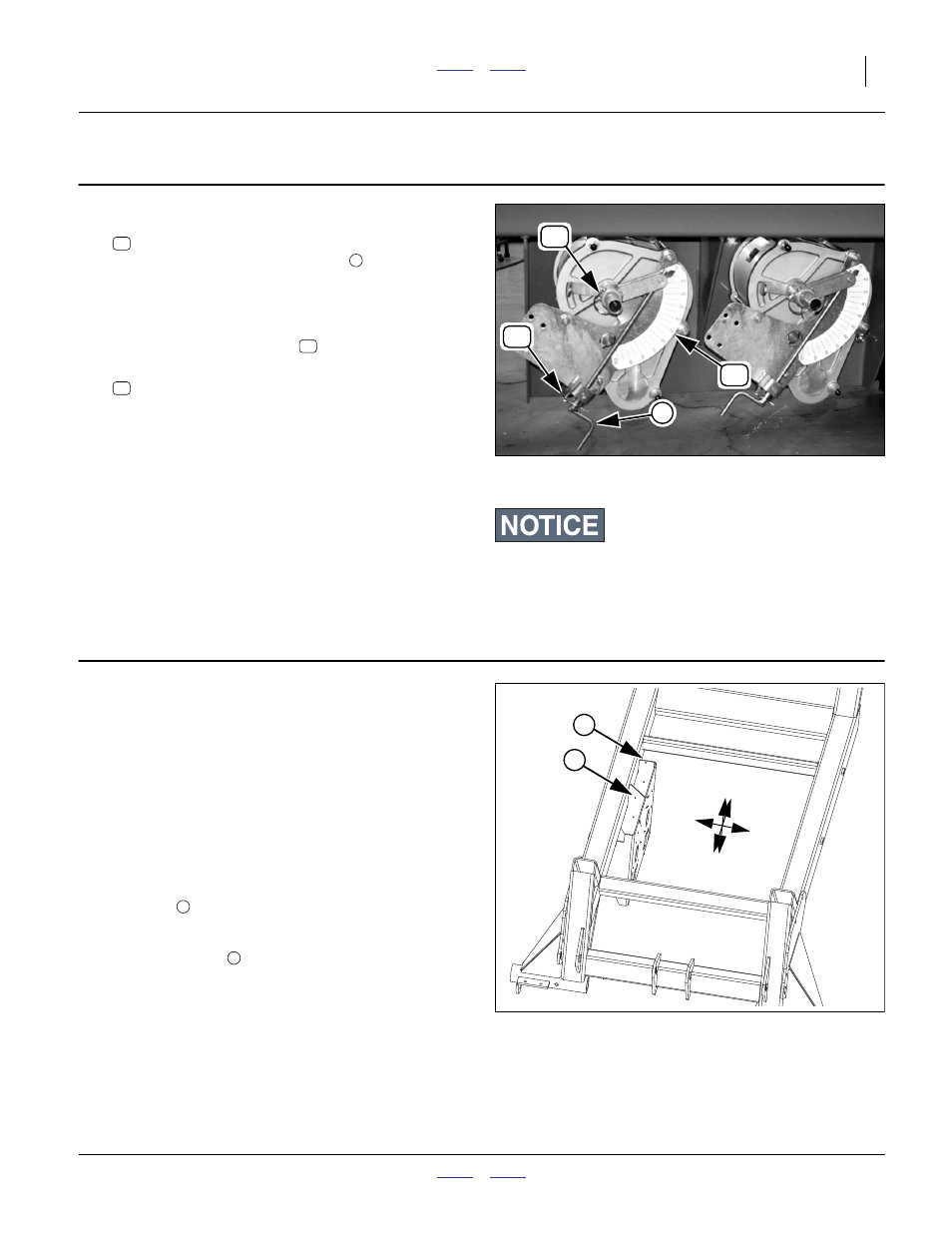

Prepare Meters

Refer to Figure 4

18. At a variable rate gearbox, remove the:

805-032C PIN HAIR COTTER .148 WIRE

then use the existing control crank

actuator to set

the indicator to 0 on the 0-100 scale. This prevents

the jackscrew from obscuring the scale.

Adjust the final crank handle position to fully down,

and re-insert the cotter pin

.

19. Remove and save the:

805-065C PIN WIRE RETAINING 1/4 X 1 3/4

This pin is re-used at step 41 to couple the new con-

trol arm to the gearbox control shaft.

Note: Removing this pin de-couples the gearbox control

shaft from the manual adjustment system. If it is

ever necessary to revert to manual control, move

the pin back to the manual arm.

20. Repeat step 18 and step 19 for the other meter.

Prepare ADC Driver Mounts

If your implement is an NTA607HD, NTA907HD,

NTA2007HD or NTA3007HD, continue at step 24 on

page 7.

On older ADC2350/B carts, the mounting holes for the

actuator driver modules may not be present, and must be

drilled. Newer ADC2350 carts, all NTA607/2007HD and

all NTA3007/907HD drills have holes present.

Refer to Figure 5

21. Locate the mounting holes on the ADC2350/B air

cart. These are 0.28x0.38in (7.1x95mm) slotted

holes 5.84in (14.8cm) apart.

One pair

is located on the forward break of the

gearbox mount plate.

The second pair

are located on the brace plate at

the center of the gearbox mount plate.

If these holes are present, continue at to step 24 on

page 7.

Equipment Damage Risk:

Never operate the meters with pins in both the manual/crank

arm and the linear actuator arm.

Figure 4

Existing (Manual) Meters

26306

3

50

52

51

52

52

51

Figure 5

ADC Driver Mounting Holes

29508

U

D

F

B

R

L

4

5

4

5