Calibrate, Example calibration screen, Calibrate speed sensor – Great Plains VARIABLE RATE KIT Operator Manual User Manual

Page 18: Calibrate material, Pm near field speed at step 92

18

Air Drill Variable Rate Kit

Great Plains Mfg., Inc.

166-263M

6/23/2010

Calibrate

Calibrate Speed Sensor

88. Perform a Calibrate Ground Speed.

Calibrate Material

Perform a calibration. The procedure is similar to that for

crank-set operations.

89. Consult the Seed Rate manual (167-085B) for (the

approximate) manually-set rate for your material.

90. Check that final Range gear pairing is the same on:

• the chart,

• the meter, and

• the Meter gear Range in the Channel Setup.

91. Enter the calibration screen.

At this time, the linear actuator becomes active. The

scale indicator moves to approximately mid-scale,

then stops.

Pointing to a specific value is not required, but

needs to be in the range 30

° to 95°. Great Plains

recommends using a scale setting that is close to

your expected target rate.

Use the Inc+/Dec- softkeys on the monitor console

to adjust the indicator to the target rate, or at least to

within the 30

°-95° range.

92. Manually crank the meter for at least the number of

turns shown in the instruction of the Seed Rate

Manual for

1

⁄

10

ha or

1

⁄

10

ac.

The exact number of revolutions, cranking rate

b

,

and precise starting and stopping handle angles are

not critical, as the system reads meter revolutions

accurately, and can compensate for shaft speed,

seed size and partial turns.

What matters is getting a large sample, to reduce

errors and increase confidence in the calibration.

Note: By calibrating at the target rate, and for

1

⁄

10

ha, you

establish a comfort level that the drill is set up cor-

rectly, in particular, that you are in the correct gear

Range for the desired application rate.

93. Weigh the dispensed material and enter it in the

menu. The monitor computes a Calibration Con-

stant for this material. Save this result.

b. If no “Variable Cal Const” was selected at step 84, crank at for most accurate results:

ADC2350/B, NTA907/3007HD: 2 to 2

1

⁄

2

revolutions per second

NTA607/2007HD: 1 to 1

3

⁄

4

revolutions per second

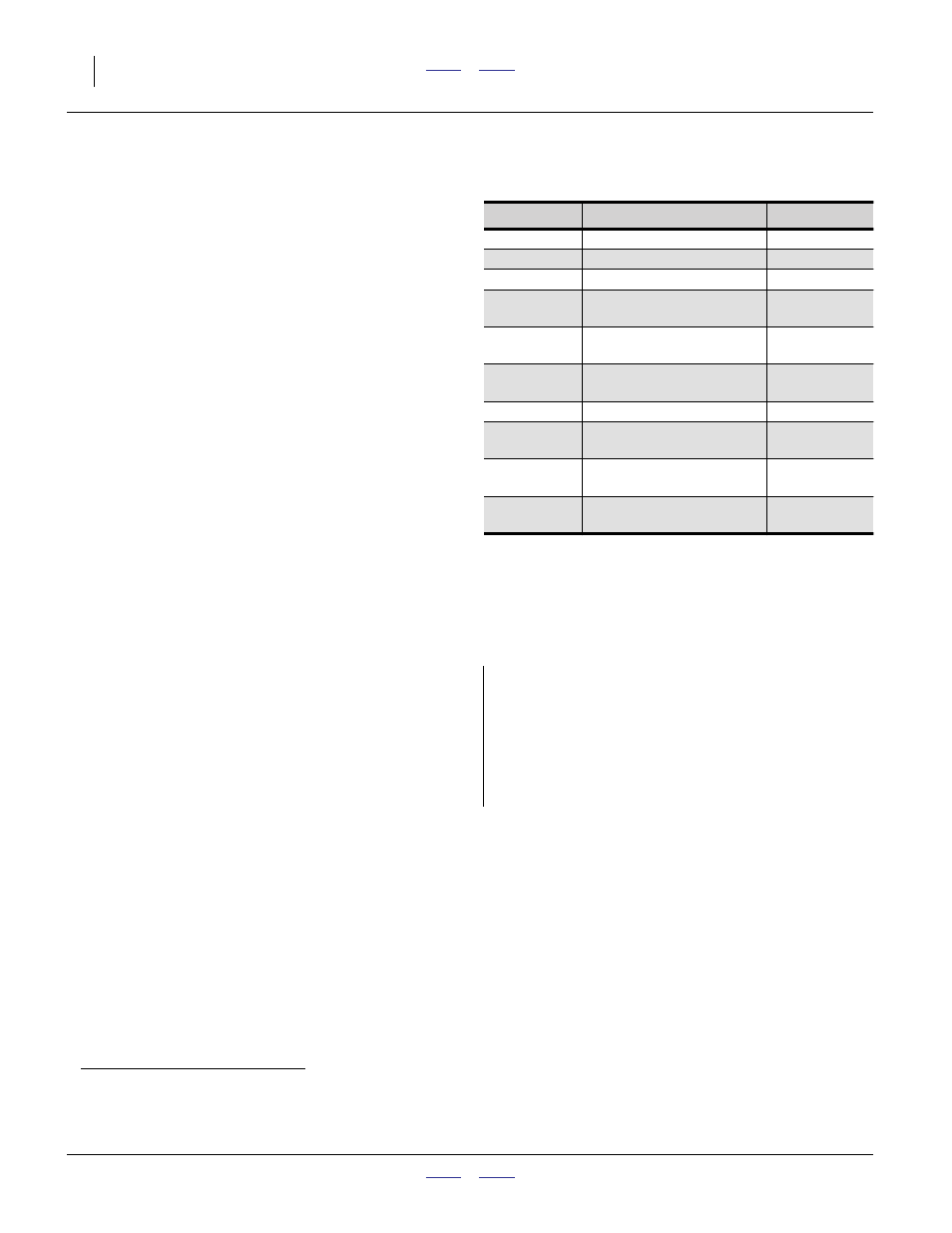

Example Calibration Screen:

Parameter

Value

Comment

CHANNEL

1

Example

material

Example

Density

60.0

LB/BU

Example

Calibration

Constant

PUL/FT

From chart

Target Meter

rpm

20

RPM

Example

# Meter

Revs

30

REV

Example

Pulse Count 0

PUL

Pre-Cal.

New Calib

Const

______

PUL/FT

Total #

Towers

5

Per Imple-

ment

Amount

Dispensed

______

LBS

From Scale

Example:

ADC2350B cart and NTA3510 drill

Wheat, 2-star meter, single seed hopper in use

High Range at gearbox

Target rate of 133 kg/ha would be a scale setting of:

50

° (from Seed Rate manual charts)

A sample size of

1

⁄

10

ha requires crank:

77 turns (from Seed Rate manual instructions)