Create a controlled material, Example non-preset material setup – Great Plains VARIABLE RATE KIT Operator Manual User Manual

Page 16

16

Air Drill Variable Rate Kit

Great Plains Mfg., Inc.

166-263M

6/23/2010

Create a Controlled Material

Re-define at least one material. Otherwise, create at

least one material. Some key steps:

80. Type must be set to GRAN SEED CONTROL or

GRAN FERT CONTROL.

81. Select or Disable: Preset Method

If using preset method, select initial rate increments

that are only a few percent, so as to have fine con-

trol of the meter scale indicator. These can be

changed to coarser increments after calibration.

82. Density must be accurately entered.

83. Enter the Cal Const if one is available for your seed

type. This value does not affect the calibration pro-

cess, and is replaced during calibration, but is use-

ful for comparison. The calibration constant

developed during calibration should be similar to the

chart number.

84. Set Variable Cal Const if one is available for your

seed. This is from a list of names pre-programmed

into the monitor software. It is usually not the same

name as the material name setup on page 15. In

this example, “Wheat 2S”, the “2S” refers to the

(factory standard) “2 star” meter flute configuration.

Pick a seed constant closest to yours in terms of

physical seed characteristics and meter flute config-

uration.

If a suitable Variable Cal Const is available, the sys-

tem can more accurately compensate for manual

calibration cranking speeds that differ from field

rate.

If no suitable Variable Cal Const is available, crank

at an rpm near field speed at step 92.

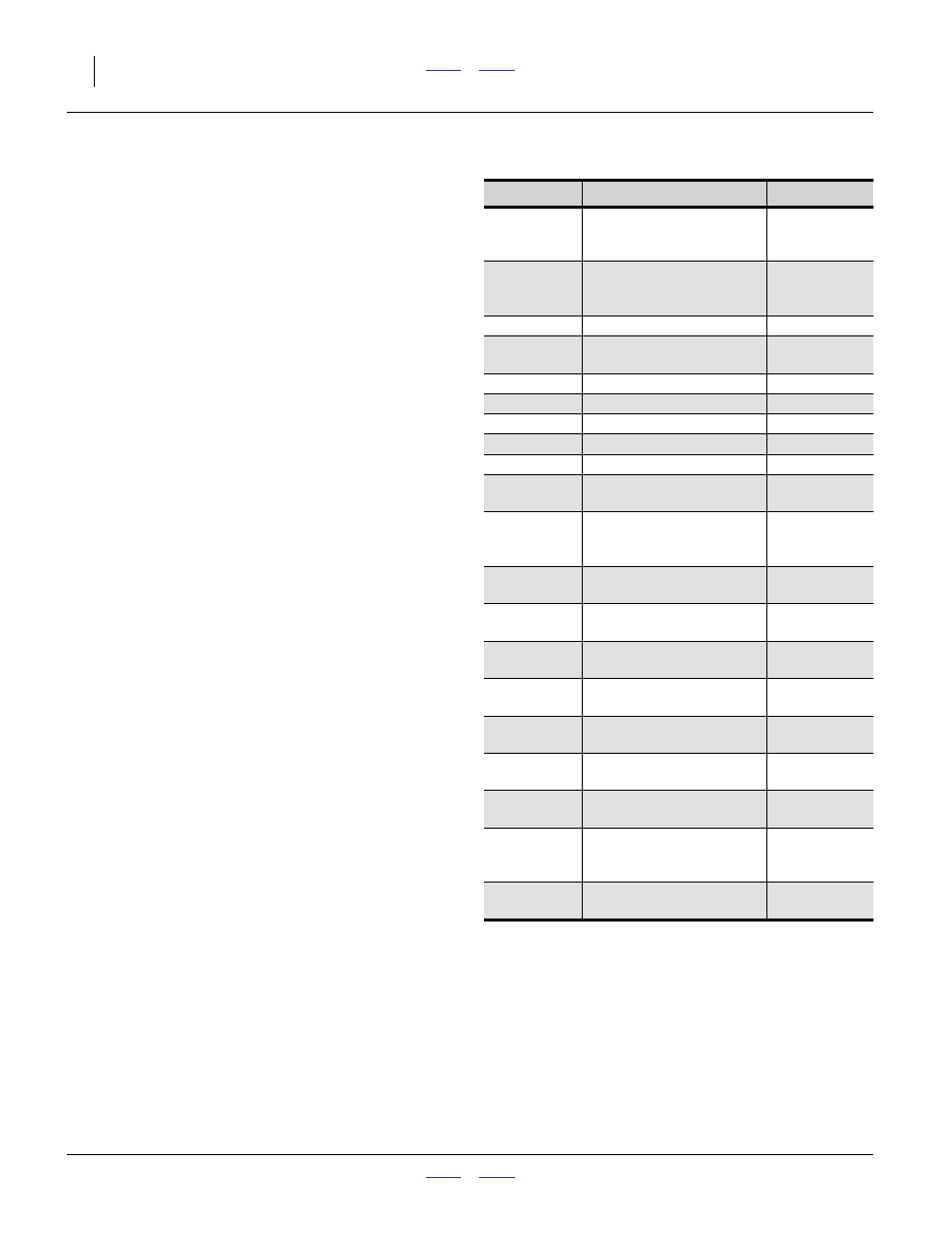

Example Non-Preset Material Setup:

1-16

CH Wheat HRW

Comment

CHANNEL

1 or 2

Per meter

being config-

ured

Type

GRAN SEED CONTROL

or

GRAN FERT CONTROL

Must be one

of these

Units

Lb/ac with Rev/ac

Example

Preset

Method

Disabled

Example

Target Rate

60.0

LB/AC

Example

Max Rate

78.0

LB/AC

Upper + limit

Min Rate

48.0

LB/AC

Lower - limit

Inc/Dec %

1.0

%

Example

Density

60.00

LBS/BU

Example

#Towers

5

Per Imple-

ment

Cal Const

77591

Optional: Use

nearest chart

value

Variable Cal

Const

Optional

Shaft RPM

Low 10

High 50

RPM

Prod Level

Alarm

0

LBS

Seeds per

Pound

3000

S/LB

Example

High Pop

Alarm

20.0

%

Example

Low Pop

Alarm

20.0

%

Example

ROW

WIDTH

__

IN

Or use Auto-

Update Width

ON(-)/

OFF(X)

PATTERN

-------------------------

(unless tramline in use)

Row Fail

Rate

2 / 1

S/SEC

See ACC

manual