Cb a, Assembly – Viking Pump TSM153: N-R 333/4333 User Manual

Page 7

c

B

a

SECTION TSM 153

ISSUE

D

PAGE 7 OF 16

ASSEMBLY

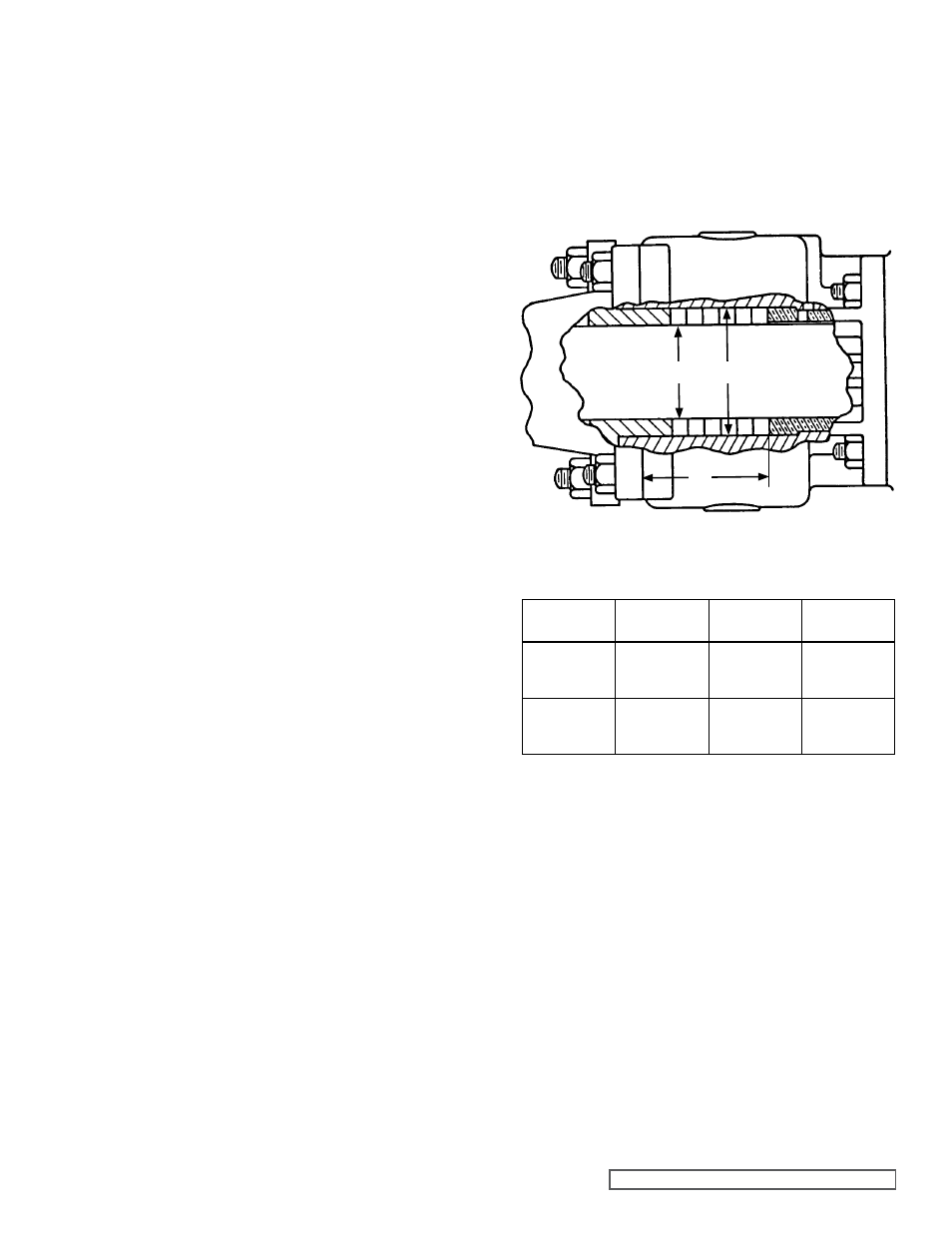

FIgURE 8

STUFFINg BOX DIMENSIONS

1. Install rotor bearing sleeve and gasket on casing. Coat

both sides of gasket with thread sealant (pipe dope) and

quickly install gasket and rotor bearing sleeve on casing.

Place a support under rotor bearing sleeve to prevent

casing and rotor bearing sleeve from tilting down while

rotor is being installed.

2. Check casing to be sure drain plug has been removed.

3. Carefully check shaft, remove any burrs or rough surfaces

to avoid damaging rotor bearing sleeve bushing while

installing rotor and shaft into casing. Coat inner diameter

of rotor bearing sleeve bushing and shaft with a thin coat

of non-detergent SAE 30 weight oil.

Support weight of rotor with a hoist. A cable sling can be

used around shaft, or around rotor teeth, to carry weight

of part while being assembled into casing.

Place end of rotor shaft through casing, into bushing

slowly turn rotor from right to left while pushing into

casing. When shaft first protrudes from stuffing box,

stop pushing. Check to see if large diameter of shaft has

protruded far enough into rotor bearing sleeve to permit

installing packing rings.

Use packing suitable for liquid being pumped. Lubricate

packing rings with oil, grease or graphite to aid assembly.

Packing ring joints should be staggered from one side

of shaft to the other. A length of pipe will help set each

packing ring.

4. Place packing gland and inner end cap (spanner wrench

holes on side next to packing gland) with lip seal (lip

facing away from packing gland) over end of shaft.

5. Push rotor far into casing as far as it will go.

6. Prior to installing head, coat casing face with thread

sealant (pipe dope) and place a new .015” head gasket

on mounting studs. Coat dry side of gasket with thread

sealant (pipe dope) and prepare to mount head on idler

assembly.

Pump head and casing were marked before disassembly

to ensure proper reassembly. If not, be sure idler pin,

which is offset in pump head, is positioned toward and

equal distance between port connections to allow for

proper flow of liquid through pump. Place head on pump,

slightly tilting top of head away from casing until crescent

enters inside diameter of rotor. Rotate idler on idler pin

until idler teeth mesh with rotor teeth. Raise head until

face of head is parallel with face of casing and work into

position. Care must be taken to avoid damaging head

gasket. Fasten head to casing with nuts and tighten

evenly.

If relief valve was not removed from head, install on

head with adjusting screw cap pointed toward such port.

Refer to Figure 2, page 2. For PRESSURE RELIEF

INSTRUCTIONS, REFER TO PAgE 14.

7. Push rotor back against head.

8. Install drain plug in casing.

9. Pack pump with new packing. Refer to Figure 8. Models

N and R333 have 6 rings of packing.

10. Install thrust bearing housing on end of rotor ring sleeve

and tighten nuts and capscrews securely. It is not

necessary to use gasket between these parts.

PUMP

MODEL

A

(INCH)

B

(INCH)

C

(INCH)

N333

4.625”

4.688”

3.438”

R333

4.625”

4.688”

3.438”