Assembly – Viking Pump TSM153: N-R 333/4333 User Manual

Page 12

SECTION TSM 153

ISSUE

D

PAGE 12 OF 16

INLET

OR

SUCTION

OUTLET

OR

SUCTION

RELIEF

VALVE

ADJUSTINg

SCREW

ASSEMBLY

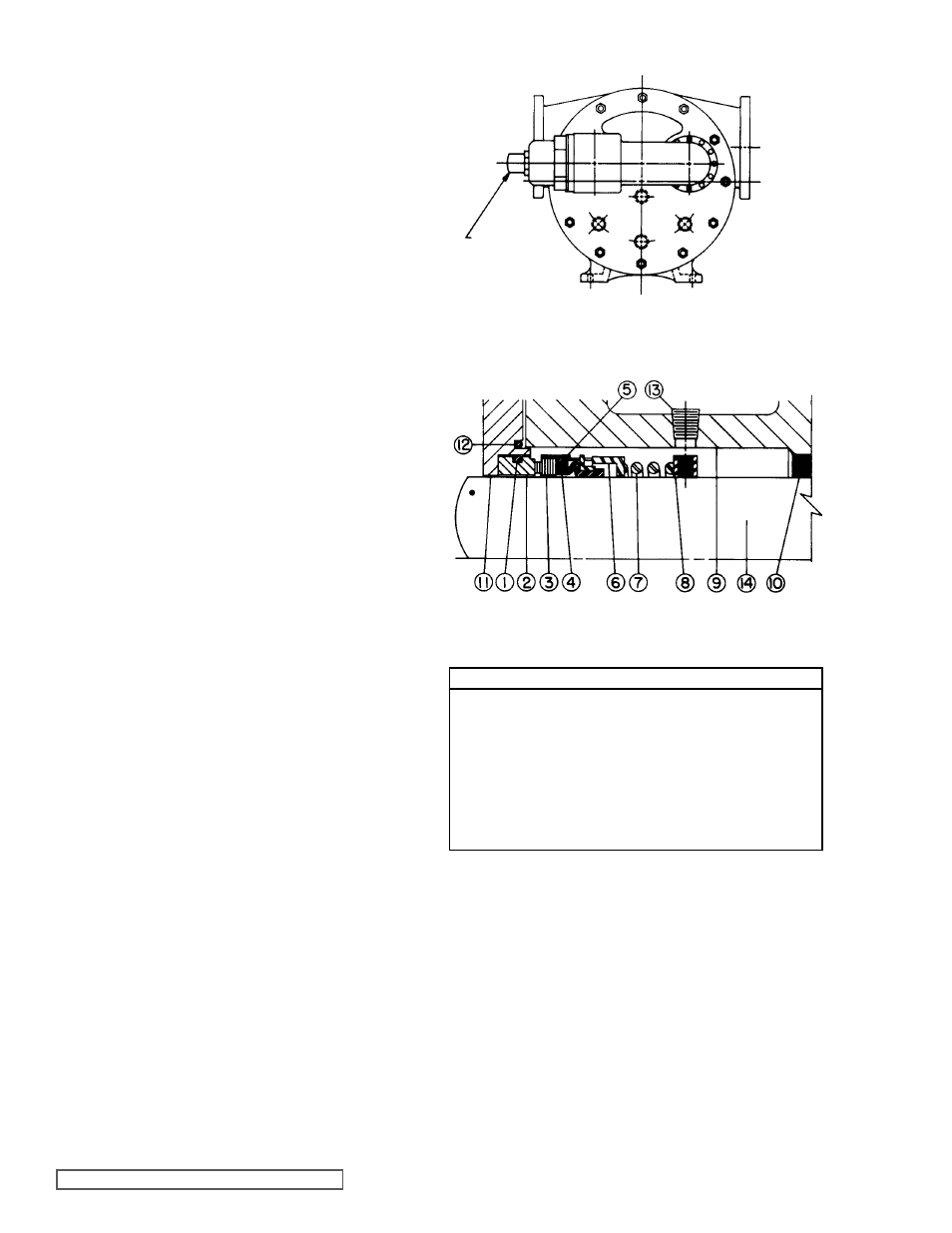

FIgURE 15

FIgURE 16

MECHANICAL SEAL

Standard Mechanical Seal (Synthetic Rubber Bellows Type)

Prepare all parts for reassembly ahead of time. Pack roller

bearings with multi-purpose grease, NLGI # 2 and have all

new gaskets on hand.

Be especially careful to keep mechanical seal parts clean.

Minute dirt particles especially on seal fences, will cause

leakage. Never touch seal fences with anything except clean

hands or clean cloth.

Once rotating position of mechanical seal is installed on

rotor shaft, it is necessary to assemble parts as quickly as

possible to ensure seal does not stick to shaft in the wrong

axial position. The seal should be expected to stick to shaft

after several minutes setting time.

1. Deburr threads on rotor shaft with a fine file and place a

layer of tape over threads to protect rotor bearing sleeve

bushing during assembly. Gently radius leading edge of

largest diameter on shaft (.03 inch is sufficient to aid in

seal installation). Smooth radius with crocus cloth. Polish

rotor shaft from leading edge through mechanical seal

area with crocus cloth. Any scratches left on shaft in seal

area will provide leakage paths under mechanical seal.

2. Install rotor bearing sleeve and gasket on casing. Coat

both sides of gasket with thread sealant (pipe dope) and

quickly install gasket and rotor bearing on casing. Place

a support under rotor bearing sleeve to prevent casing

and rotor bearing sleeve from tilting down while rotor is

being installed.

3. Check casing to be sure drain plug has been removed.

4. Coat inner diameter of rotor bearing sleeve bushing with

a thin coat of non-detergent SAE30 weight oil.

Support weight of rotor with a hoist. A cable sling can be

used around shaft, or around rotor teeth, to carry weight

of part while being assembled into casing.

Place end of rotor shaft through casing into bushing. Do

not allow any portion of shaft to strike bushing. A carbon

graphite bushing can be severely damaged if struck.

Slowly turn rotor from right to left while pushing into

casing. Push rotor as far into casing as it will go.

5. Prior to installing head, coat casing face with thread

sealant (pipe dope) and place new .015 inch head gasket

on mounting studs. Coat dry side of gasket with thread

sealant (pipe dope) and prepare to mount the head and

idler assembly.

6. Pump head and casing were marked before disassembly

to ensure proper reassembly. If not, be sure idler pin,

which is off set in pump head, is positioned toward an

equal distance between port connections to allow for an

even flow of liquid through pump.

Place head on pump, slightly tilting top of head back

away from casing until crescent enters inside diameter of

rotor. Rotate idler on idler pin until idler teeth mesh with

rotor teeth. Raise head until face of head is parallel with

face of casing and then work into position. Care must be

taken to avoid damaging head gasket. Fasten head to

casing with head nuts and tighten evenly.

If relief valve was removed from head, install on head

with adjusting screw cap pointed toward suction port.

Refer to figure 19 for PRESSURE RELIEF VALVE

INSTRUCTIONS, page 14.

LIST OF PARTS

1. O-Ring Seat Gasket

8. Set Collar with Setscrews

2. Stationary Seat

9. Rotor Bearing Sleeve

3. Rotating Face (Washer) 10. Rotor Bearing Sleeve Bushing

4. Bellows

11. Seal Holder Plate

5. Metal Parts

(Retainer, drive band)

12. O-Ring Gasket for seal

holder plate

6. Spring Adapter

13. Pipe Plug

7. Spring

14. Shaft

Note:

Items 1 through 7 comprise the complete mechanical seal.

7. Push rotor back against head.

8. Install drain plug in casing.

9. Wipe shaft clean in seal area and thoroughly coat with

non-detergent SAE 30 weight oil.

Before installing parts contained in the mechanical seal,

refer to figure 20 to become familiar with part name and

location in rotor bearing sleeve.

10. Install set collar on shaft in rotor bearing sleeve directly

under tapped access hole. Center line of collar set

screws (5/16” socket head) must line up with center line

of access hole. Rotate shaft and tighten all setscrews.

Replace pipe plug in seal access hole.