Disassembly – Viking Pump TSM153: N-R 333/4333 User Manual

Page 10

SECTION TSM 153

ISSUE

D

PAGE 10 OF 16

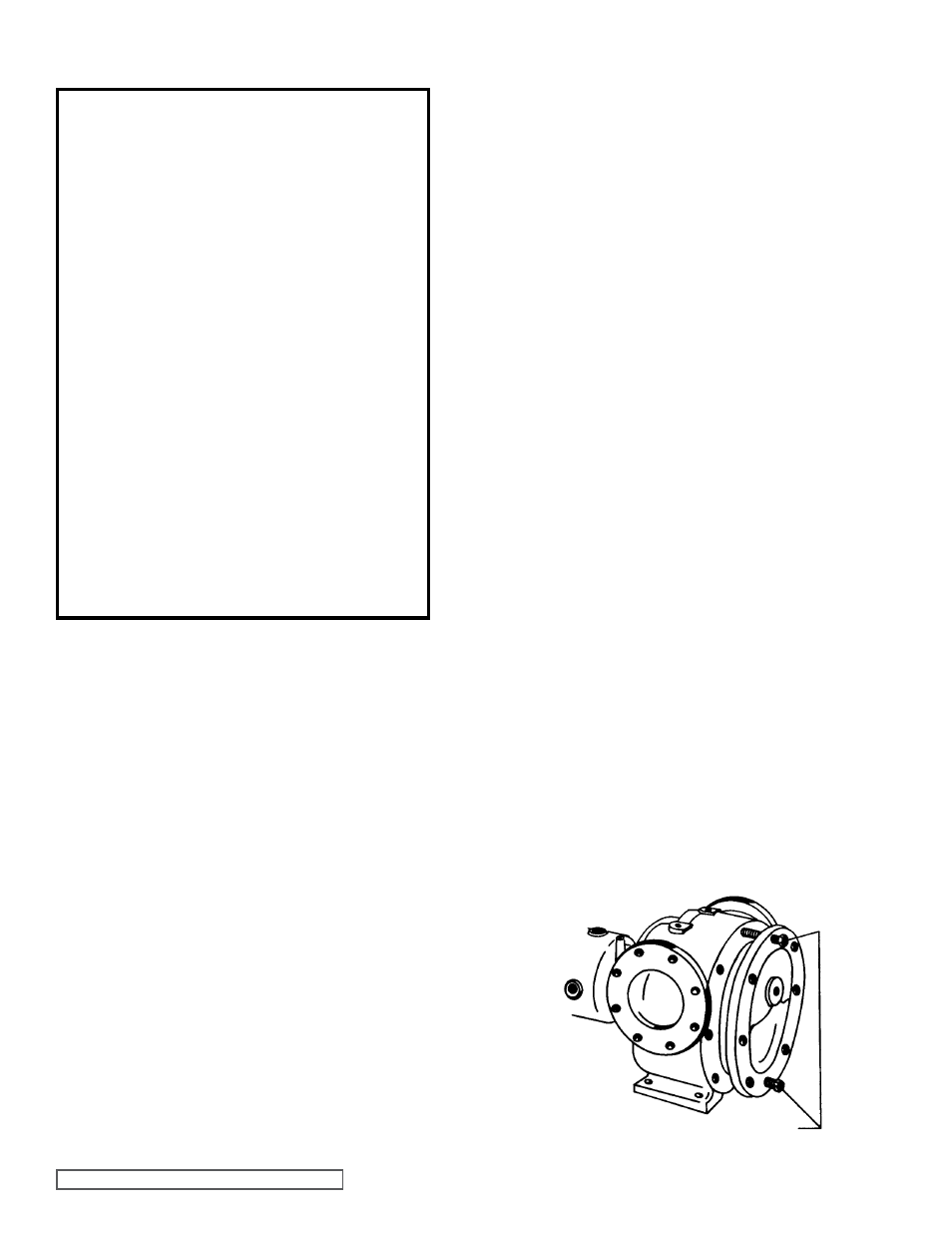

JACKSCREWS

DISASSEMBLY

DANgER !

Before opening any Viking pump liquid

chamber (pumping chamber, reservoir,

relief valve adjusting cap fitting, etc.)

Be sure:

1. That any pressure in the chamber has

been completely vented through the

suction or discharge lines or other

appropriate openings or connections.

2. That the driving means (motor,

turbine, engine, etc.) has been “locked

out” or made non-operational so that

it cannot be started while work is

being done on pump.

3. That you know what liquid the

pump has been handling and the

precautions necessary to safely

handle the liquid. Obtain a material

safety data sheet (MSDS) for the

liquid to be sure these precautions

are understood.

Failure to follow above listed

precautionary measures may result in

serious injury or death.

FIgURE 11

1. Mark head and casing before disassembly to ensure

proper reassembly. The idler pin, which is offset in pump

head, must be positioned toward and equal distance

between port connections to allow for proper flow of

liquid through pump.

It is not necessary to remove relief valve to take head

off pump; however, removing removing relief valve

will lessen total weight of part. Do not use chain or

cable around relief valve body to support head during

removal.

Remove nuts from head. Jackscrews should be used to

back head away from casing.

Refer to figure 11. Proper

size and length of jackscrews for pump size are shown

in

figure 12. The use of a hoist to support head will

facilitate its removal.

Back head away from casing, Remove head from pump.

Do not allow idler to fall from idler pin. To prevent this, Tilt

top of head back when removing.

2. Remove head gasket, idler and bushing assembly.

3. To remove rotor, loosen set collar behind mechanical

seal. Through the one inch jacket connection on top of

rotor bearing sleeve, remove 0.25” socket head pipe

plug.

Through the same hole loosen the 0.313” socket head

setscrews which lock collar to shaft. Rotate shaft to be

sure all setscrews have been loosened.

Refer to figure

10, page 8, items 16 and 17, for pipe plug to remove the

setscrews to loosen.

4. Remove casing drain plug to break vacuum between

back of rotor and casing. Remove any deposit of material

from exposed portion of shaft between seal plate and

thrust bearing assembly.

5. Insert

length of hardwood or brass through port opening

between rotor teeth to keep shaft from turning.

6. Bend up tang on lockwasher and with a spanner wrench,

remove locknut and lockwasher from shaft.

Refer to

figure 13.

7. Remove length of hardwood or brass bar from port

opening.

8. Cushion end of shaft with a hardwood block or piece of

brass and drive rotor out of casing being careful to avoid

damaging rotor bearing sleeve bushing.

Support weight of rotor with a hoist. A cable sling can be

used around shaft, or around rotor teeth to carry weight

of part.

9. Loosen end cap lockscrews, disengage end cap locks

and with a spanner wrench, remove end caps. Examine

lipseal and replace if worn.

Remove roller bearings.

10. Remove nuts and capscrews and take off thrust bearing

housing.

11. Remove nuts holding seal plate and remove seal plate.

The stationary seal seat can be removed from seal

plate and rotating portion of seal from rotor bearing

sleeve, remove spring and set collar from bottom of seal

chamber.

12. Check rotor bearing sleeve bushing while rotor bearing

sleeve is mounted on casing. If worn bushing must be

replaced.

Disconnect flush line and remove rotor bearing sleeve

from casing.

A press must be used to remove old bushing. If bushing

has a shoulder on stuffing box end, it must be pressed

out mechanical seal end of rotor bearing sleeve.

Carbon graphite bushings are standard for Model 4333

pumps. To replace carbon graphite bushings,

refer to

INSTALLATION CARBON gRAPHITE BUSHINgS,

page 14.