Viking Pump TSM153: N-R 333/4333 User Manual

Page 6

SECTION TSM 153

ISSUE

D

PAGE 6 OF 16

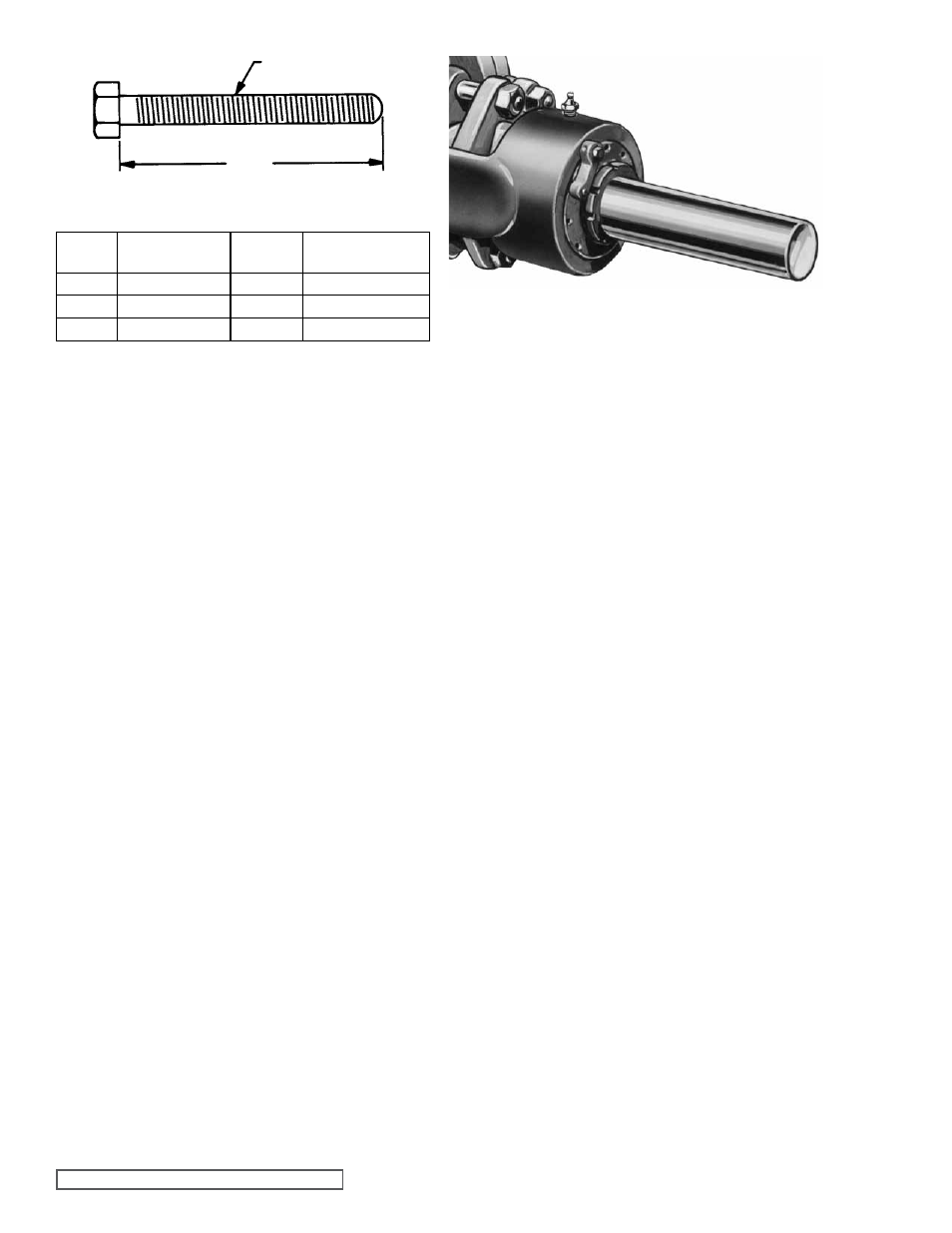

THREAD SIZE

a

MINIMUM LENgTH OF JACK SCREWS

FIgURE 6

FIgURE 7

LOCKWASHER WITH TANg

LOCKNUT

PUMP

SIZE

NO. SCREWS

USED

a

THREAD SIZE

(INCH)

N

2

4.00

0.50” - 13 NC

R

2

4.50

0.63” - 11 NC

P

3

5.00

0.50” - 13 NC

2. Remove head gasket, idler and bushing assembly.

3. Remove pipe plug from drain hole in casing, this breaks

vacuum behind rotor.

4. Remove packing gland nuts and slide gland out of rotor

bearing sleeve.

5. Insert length of hard wood or brass bar through port

opening between rotor teeth to keep shaft from turning.

6. Bend up tang on lock washer and with a spanner wrench;

remove locknut and lockwasher from shaft.

Refer to

figure 7.

7. Remove length of hardwood or brass bar from port

opening.

8. Cushion end of shaft with a hardwood block or piece of

block and drive rotor out of casing, being careful to avoid

damaging rotor bearing sleeve bushing. Support weight

of rotor with a hoist. A cable sling can be used around

shaft, or around rotor teeth, to carry weight of part.

9. Loosen end cap lockscrews, disengage end cap locks

and with a spanner wrench remove end caps. Remove

roller bearings.

10. Remove nuts and capscrews and take off thrust bearing

housing. Remove packing from rotor bearing sleeve.

11. Check rotor bearing sleeve bushing while rotor bearing

sleeve is mounted on casing. If worn, bushing must be

replaced.

Disconnect suck back line and remove rotor bearing

sleeve from casing. A press must be used to remove

old bushing. If bushing has a shoulder on the stuffing

box end, it must be pressed out packing end of rotor

bearing sleeve. If bushing is carbon graphite,

refer to

INSTALLATION OF CARBON gRAPHITE BUSHINgS,

page 14

12. Clean all parts thoroughly and examine for wear and

damage. Check idler bushing and idler pin, replace if

necessary.

If idler pin is to be replaced, oil must be installed facing

center of crescent head.

If lipseals need replacement, press in end cap with lip

facing end of shaft.

If idler bushing is to be replaced, a press must be used to

remove old bushing and install new. Bushing position after

being pressed in should be flush with face of idler. For

carbon graphite idler bushing,

refer to INSTALLATION

OF CARBON gRAPHITE BUSHINgS, page 14.

Wash anti-friction bearings (roller bearings) in clean

solvent. Blow out bearings with compressed air. Do

not allow bearings to spin; turn bearing slowly by

hand. Spinning bearings will damage race and rollers.

Make sure bearings are clean, then lubricate with non-

detergent SAE 30 weight oil and check for roughness.

Roughness can be determined by turning outer race

by hand.

CAUTION: do not intermix inner and outer

races for roller bearings. Replace bearings if they have

roughness.

Examine casing for wear. Check condition of casing

at seal area (surface between suction and discharge

port). If surface is in good condition, casing need not be

replaced.

When making major repairs, such as replacement of a

rotor, it is usually considered advisable to install a new

head and idler. When making minor repairs, where only

an idler bushing and idler pin are required, other new

parts are usually not necessary.