Disassembly assembly, Thrust bearing adjustment – Viking Pump TSM153: N-R 333/4333 User Manual

Page 14

SECTION TSM 153

ISSUE

D

PAGE 14 OF 16

SHAFT

DISASSEMBLY

ASSEMBLY

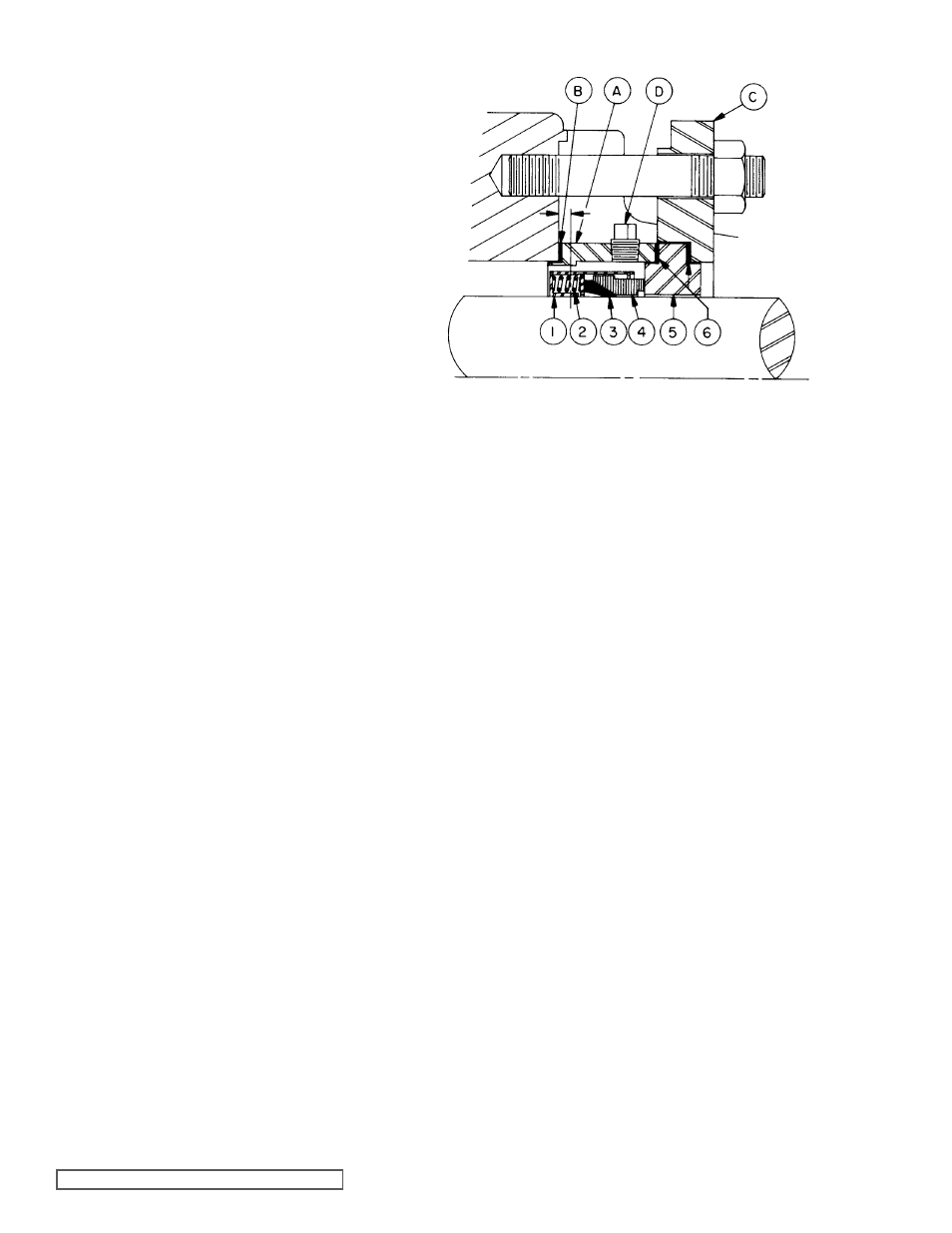

FIgURE 18

1. Disassemble pump per steps 1 thru 10 on page 9, under

MECHANICAL SEAL DISASSEMBLY.

2. Remove seal plate nuts from studs and remove seal

plate, gaskets and stationary seat.

3. If pump is equipped with a flush line, disconnect from

packing box extension.

4. Remove packing box extension and gasket.

5. Loosen set screws in mechanical seal retainer cartridge

and remove from rotor shaft. Refer to figure 18.

1. Reassemble pump per steps 1 thru 9 on pages 11 & 12,

under

Assembly, Standard Mechanical Seal. Step 1

(deburring shaft) is very critical prior to seal assembly.

2. A tapered seal installation sleeve for N & R size pumps

is available, at no extra cost, from Viking Pump.

3. Coat large diameter of shaft, tapered sleeve, and inside

diameter of seal with non-detergent SAE 30 weight oil.

4. Place tapered installation sleeve (if on hand) and install

seal on shaft over tapered sleeve. Position seal on shaft

inside rotor bearing sleeve bore with end of seal located.

19 inch inside machined face of rotor bearing sleeve.

Refer to Figure 18.

5. Tighten all seal drive set screws securely to shaft.

6. Remove tapered installation sleeve.

7. Place gasket on packing box extension and install

extension with machined pilot inside rotor bearing sleeve

bore.

8. Place seat gasket over shoulder of stationary seal seat

and insert set into seal plate. Place remaining seat

gasket over shoulder of polished surface of stationary

seat.

Refer to Figure 18.

9. Place seal plate with stationary seat over mounting studs

and push shoulder of stationary seat into packing box

extension, polished face against carbon rotating face.

10. Install nuts on mounting studs and against seal holder.

Tighten nuts evenly so seal plate and stationary seat will

not be distorted when seal is compressed.

11. Reassemble flush line to packing box extension.

AT THIS POINT, FINISH ASSEMBLY PROCEDURES

STARTINg AT STEP 18, page 12.

PTFE Fitted Mechanical Seal Assembly

For Models N-R4333, 4335 & 4337

1. Retainer Cartridge

2. Springs

3. PTFE Shaft Ring (wedge)

4. Rotating Face (washer)

5. Stationary Seal Seat

6. Seat Gaskets

Seal Mounting Parts

A. Packing box extension

B. Packing box extension gasket

C. Seal plate

D. Flush openings

THRUST BEARINg ADJUSTMENT

Use spanner wrench (provided with pump) and turn outer

end cap until rotor is tight against head and rotor shaft cannot

be turned.

With pencil or chalk, make reference mark on bearing housing

and outer end cap. Back off outer end cap approximately

4 holes. One hole is equivalent to .005” end of clearance.

Tighten inner end cap. Check rotor to determine if it turns

freely in the casing. If not, make further adjustment until rotor

does turn in casing.

Standard catalogue pumps require the following end

clearance settings; N, 015”, R, .020” minimum. Pumps built

for viscous liquid or high temperatures service may require

extra end clearance. Consult factory.

Lock both end caps securely in position with end cap locks

and screws.